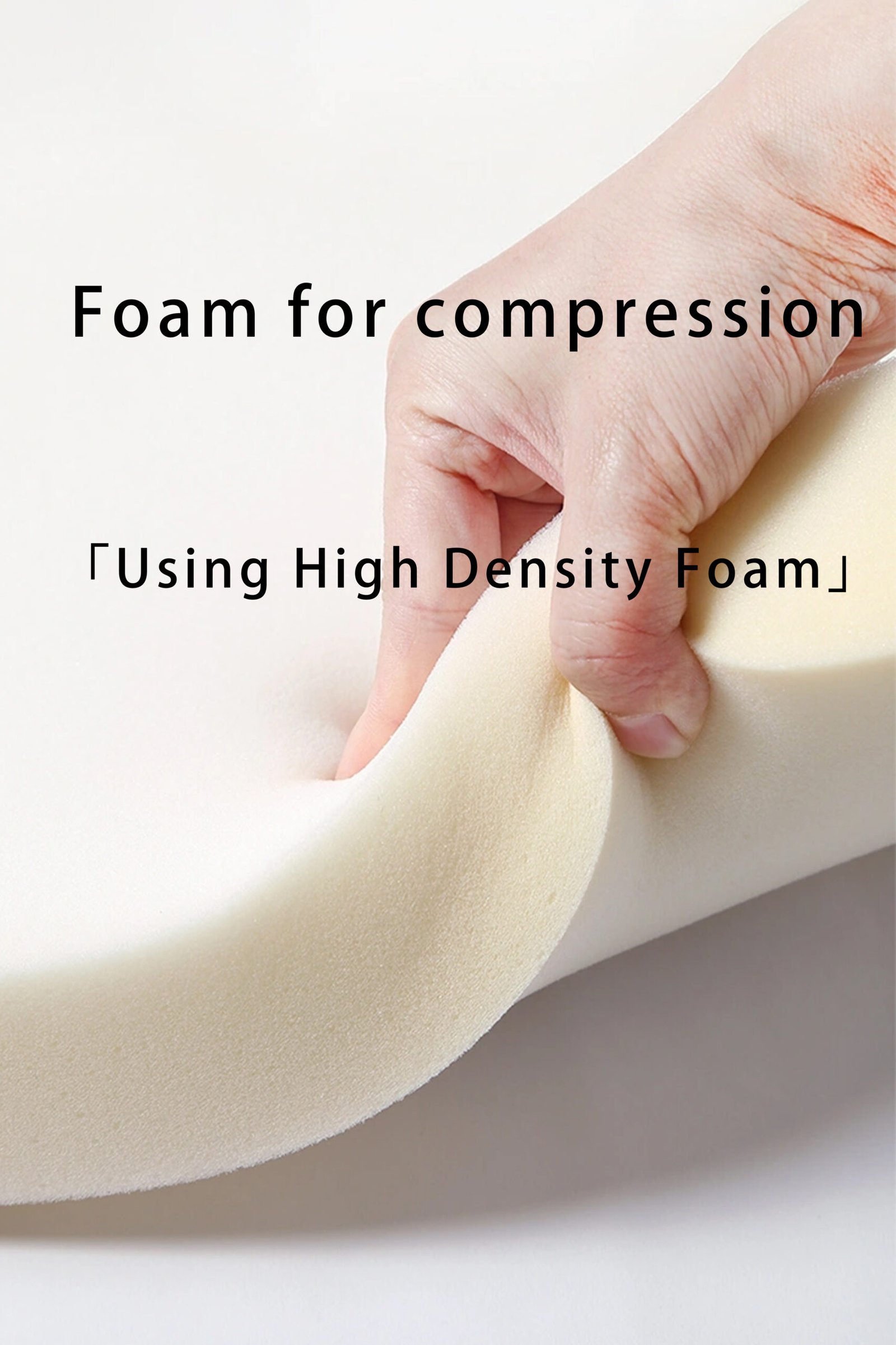

We all judge a sofa by how it looks and feels. But have you ever wondered what's underneath the cushions?

The frame material of a compression sofa is what gives it strength, shape, and long-term durability. Most use hardwood, engineered wood, metal, or plastic composites.

The wrong frame means a wobbly sofa that sags in a year. Below, I’ll break down the most common materials used in compression sofas—and how to choose the one that fits your lifestyle best.

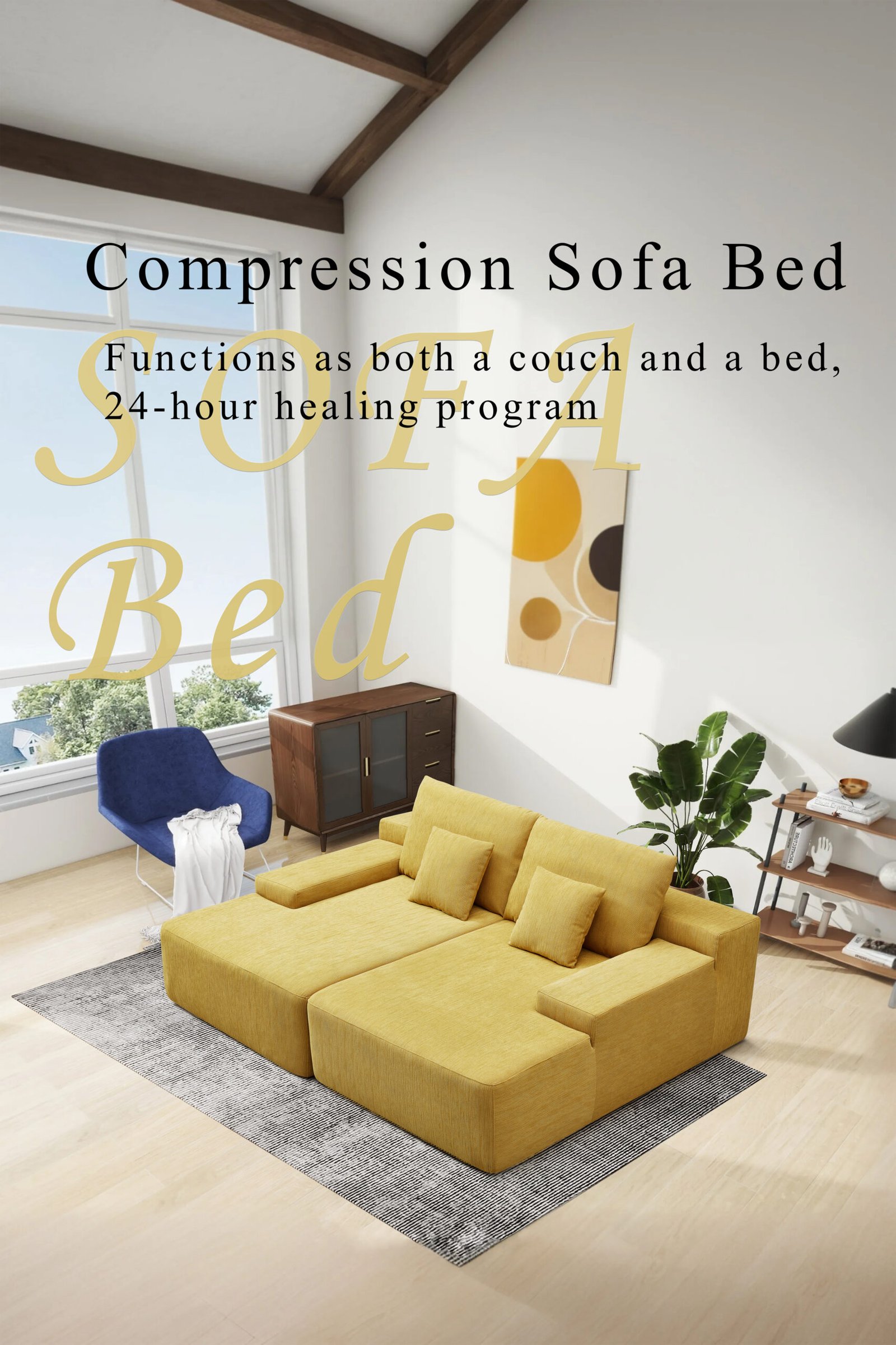

Why Does Frame Material Matter in a Compression Sofa?

Looks fade, cushions compress—but the frame is the foundation. And in compression sofas, it matters even more.

Frame material affects strength, weight, mobility, and lifespan. A strong frame keeps your sofa sturdy through daily use, compressions, moves, and reassembly.

Compression sofas are unique. They're designed to be vacuum-packed or folded, shipped in boxes, and later expanded into full-size sofas. This transformation process puts a lot of pressure on the frame. It needs to:

- Withstand heavy loads

- Bounce back after compression

- Handle frequent reconfiguration or movement

- Stay lightweight for easier delivery and setup

Now let’s look at the four major frame materials used—and what each one brings to the table.

Is Hardwood a Good Frame Material?

If you want a sofa that lasts 10+ years, hardwood is the gold standard.

Yes, hardwood frames offer maximum durability, strong joints, and a premium feel. They’re common in high-end compressed sofas.

Common Hardwood Types

- Oak – heavy, durable, and highly resistant to wear

- Maple – smooth grain, dense, and slightly lighter

- Birch – fine texture, high strength-to-weight ratio

| Property | Hardwood Frame Benefit |

|---|---|

| Strength | Excellent load-bearing |

| Aesthetic | Natural wood finish |

| Weight | Heavier than other types |

| Cost | Higher upfront investment |

I've installed oak-framed compression sofas for clients who host guests weekly. Years later, their sofas still look and feel new—no squeaks, no wobbles.

Downside? Hardwood frames are heavier, which can be inconvenient if you move often.

What About Engineered Wood?

Not every home needs hardwood—and not every budget can stretch for it.

Engineered wood frames like plywood and MDF are affordable, flexible, and common in mid-range compression sofas.

Engineered Wood Types

- Plywood – made from cross-layered wood sheets, very strong

- MDF (Medium Density Fiberboard) – smoother, denser, but not as durable

| Feature | Plywood | MDF |

|---|---|---|

| Strength | Medium-High | Medium |

| Moisture Resistance | Moderate | Low |

| Weight | Lighter than hardwood | Moderate |

| Cost | Mid-range | Budget-friendly |

Plywood is surprisingly strong for its weight. We've used it in models where the client needs something lightweight yet solid.

Pro tip: MDF can swell if exposed to moisture. If you live in a humid place, stick to plywood or sealed materials.

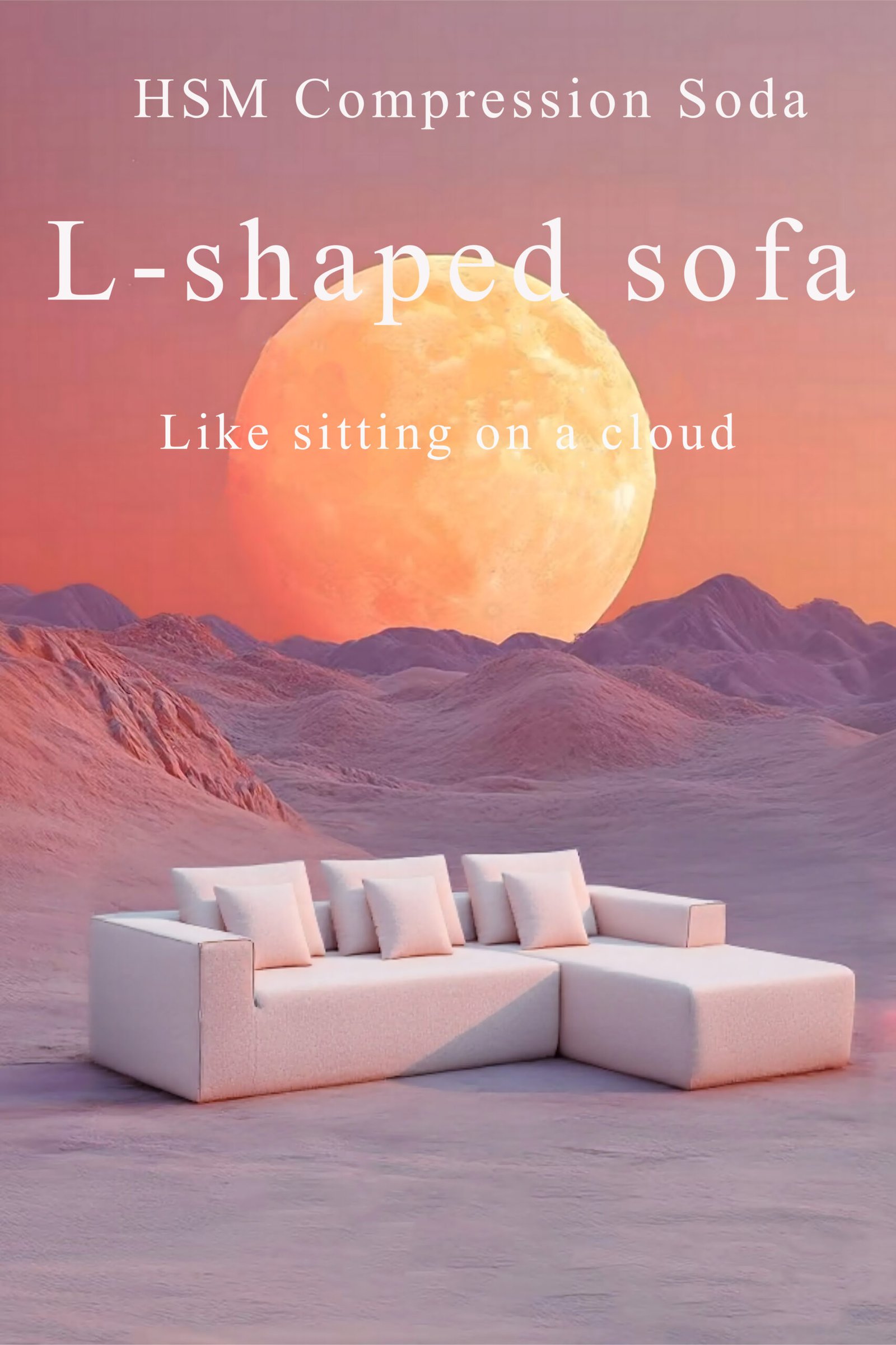

Is Metal Used in Sofa Frames?

If durability and weight are your priorities, you’ll want to consider a metal frame.

Yes, steel or aluminum frames are often used in compression sofas that need extra strength and easy portability.

Two Common Metals

- Steel – strongest option, ideal for heavy-use or commercial spaces

- Aluminum – lighter, corrosion-resistant, and good for modular frames

| Feature | Steel Frame | Aluminum Frame |

|---|---|---|

| Strength | Very High | Medium-High |

| Weight | Heavier | Light |

| Rust Resistance | Needs coating | Naturally resistant |

| Cost | Medium-High | High |

Metal frames are great for customers who move often or use the sofa in high-traffic areas. I’ve installed aluminum-framed compressed sofas in showrooms—they still feel brand-new even after hundreds of test sits.

The only thing to watch for is noise or rust. Always check that your sofa has treated, coated metal parts.

What Are Plastic Composite Frames?

Want something lightweight, affordable, and easy to handle?

Plastic composite frames are used in budget compression sofas for quick setup and low maintenance. They're mold-resistant and lightweight.

Pros and Cons of Plastic Frames

| Feature | Performance |

|---|---|

| Cost | Very Low |

| Durability | Low to Medium |

| Eco-Friendliness | Usually low |

| Weight | Very light |

Some customers prefer plastic if the sofa is short-term or for occasional use. For example, I helped a client furnish a rental property with plastic-frame sofas—they were easy to install and budget-friendly.

But I don’t recommend plastic frames for heavy daily use. They can creak, bend, or break under pressure.

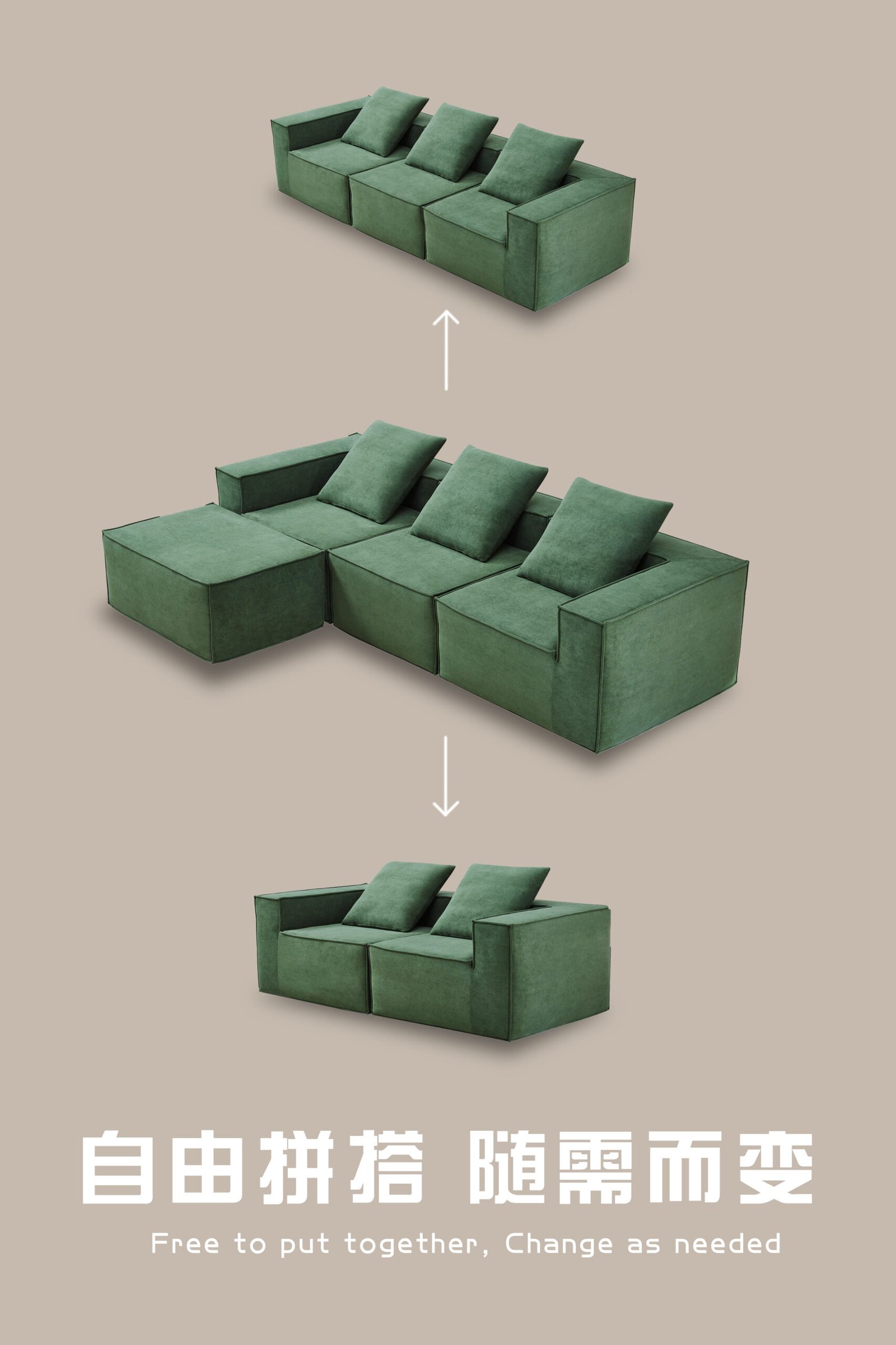

Frame Construction: Why It’s Not Just the Material

Material matters, but how it’s assembled matters just as much.

Good frames use strong joinery: corner blocks, dowels, or mortise-and-tenon joints. Weak glue or nails? Red flag.

Signs of Strong Frame Construction

- Reinforced corners

- Screws + glue (not just one)

- Metal brackets at stress points

- Solid, even base without wobble

At HSM, we always reinforce our frame joints—especially for roll-pack models—because the unpacking process adds extra pressure at the seams.

Summary Comparison Table

| Material | Durability | Weight | Cost | Best Use Case |

|---|---|---|---|---|

| Hardwood | ★★★★★ | Heavy | $$$$ | Long-term, premium sofa |

| Plywood | ★★★★☆ | Medium | $$$ | Balanced value + strength |

| MDF | ★★★☆☆ | Medium | $$ | Budget-friendly decor |

| Steel | ★★★★★ | Heavy | $$$ | High-use, heavy-duty setups |

| Aluminum | ★★★★☆ | Light | $$$$ | Modern, mobile interiors |

| Plastic Composite | ★★☆☆☆ | Very Light | $ | Short-term or rental units |

Conclusion

The frame is the heart of your compression sofa. Choose the right material—and your sofa won’t just look good, it’ll last.