Struggling with delays or uncertain timelines when sourcing compressed sofas? You're not alone. Lead time is a crucial factor that affects pricing, inventory, and customer satisfaction.

Compressed sofa suppliers typically require 30–60 days for production and delivery, depending on material availability, order volume, factory capacity, and shipping logistics.

Let’s break down why—and how you can better plan around it.

What defines the lead time for compressed sofa suppliers?

Lead time isn’t just the number of days between order and delivery. It’s a chain of events.

The total lead time includes raw material procurement, production, compression and packaging, quality checks, and transportation.

Typical stages:

| Stage | Time Range |

|---|---|

| Raw material sourcing | 5–10 days |

| Sofa production | 10–20 days |

| Compression & packaging | 2–5 days |

| Quality inspection | 2–4 days |

| Freight booking & shipping | 10–25 days (sea) |

So, the full process generally spans 30 to 60 days, but varies based on region and supplier type.

Do lead times vary by supplier type?

Yes. Lead time flexibility depends heavily on whether you're working with a manufacturer, trading company, or ready-stock wholesaler.

Breakdown:

| Supplier Type | Lead Time (Typical) | Notes |

|---|---|---|

| Manufacturer | 30–60 days | Depends on capacity and customization |

| Trading Company | 40–70 days | Adds procurement time, slower response |

| Ready-stock Dealer | 3–10 days | Limited SKUs, but fastest fulfillment |

For custom or bulk orders, factories usually need at least 45 days for proper planning and QA.

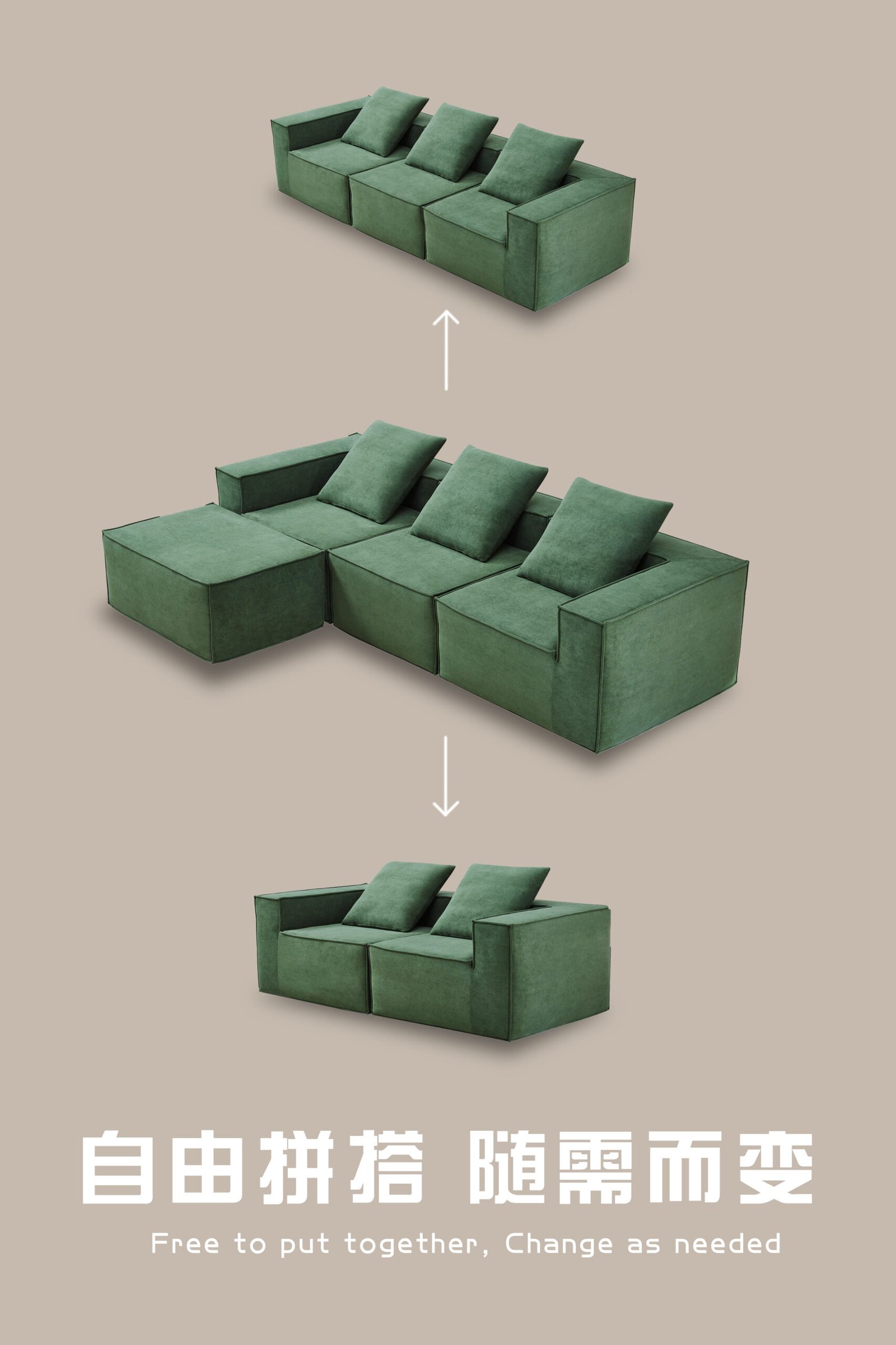

How does order size affect lead time?

Bigger orders = longer lead times. That’s because:

- More raw material is needed

- Production must be scheduled and batched

- Compression and packaging take more time

- Freight logistics must be scaled to match volume

Rule of thumb:

- MOQ (Minimum Order Quantity): 30–35 days

- Standard bulk order (1–2 containers): 45–55 days

- Large volume (3+ containers): 60+ days

If you're ordering for a seasonal promotion or retail chain, start discussions at least 2 months in advance.

What role does raw material availability play?

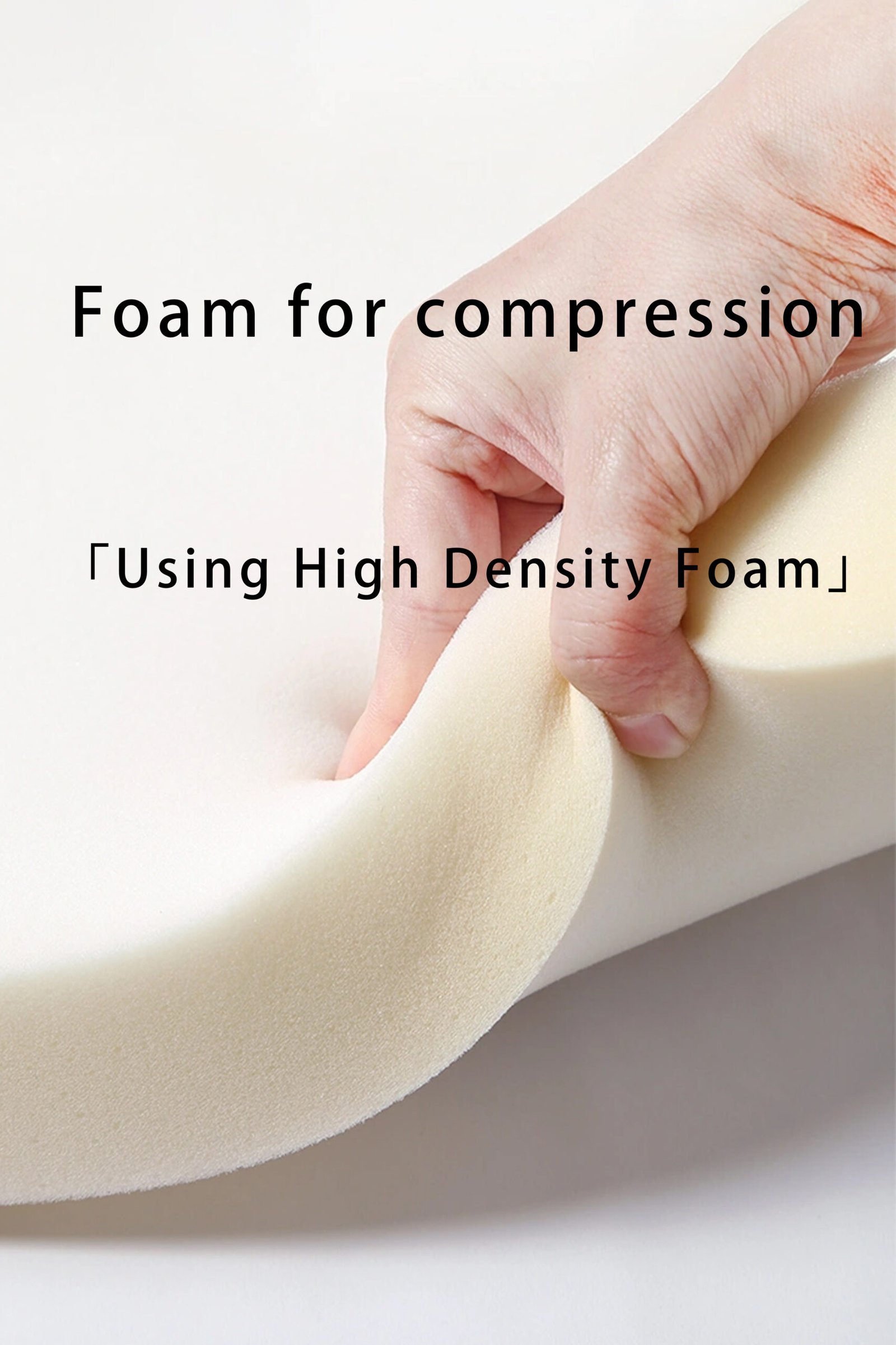

No fabric, no foam = no sofa.

Raw material delays are one of the biggest causes of extended lead times.

Common disruptions:

- High-density foam shortages

- Steel frame supplier delays

- Imported fabric or eco-leather customs holdups

How top suppliers mitigate this:

- Long-term material supplier contracts

- Buffer inventory in peak season

- Material forecasts tied to historical data

Always ask your supplier if they keep stock of key components.

What about shipping and customs?

Even if your sofa is packed and ready, shipping can add unexpected delays.

International shipping from Asia to North America or Europe can take 15–25 days by sea, plus 3–5 days for customs clearance.

Additional delays may include:

- Port congestion

- Container shortages

- Strikes or customs inspections

- Incorrect HS codes on declaration forms

If you're in a time-sensitive business, consider air freight for small batches, although it's costlier.

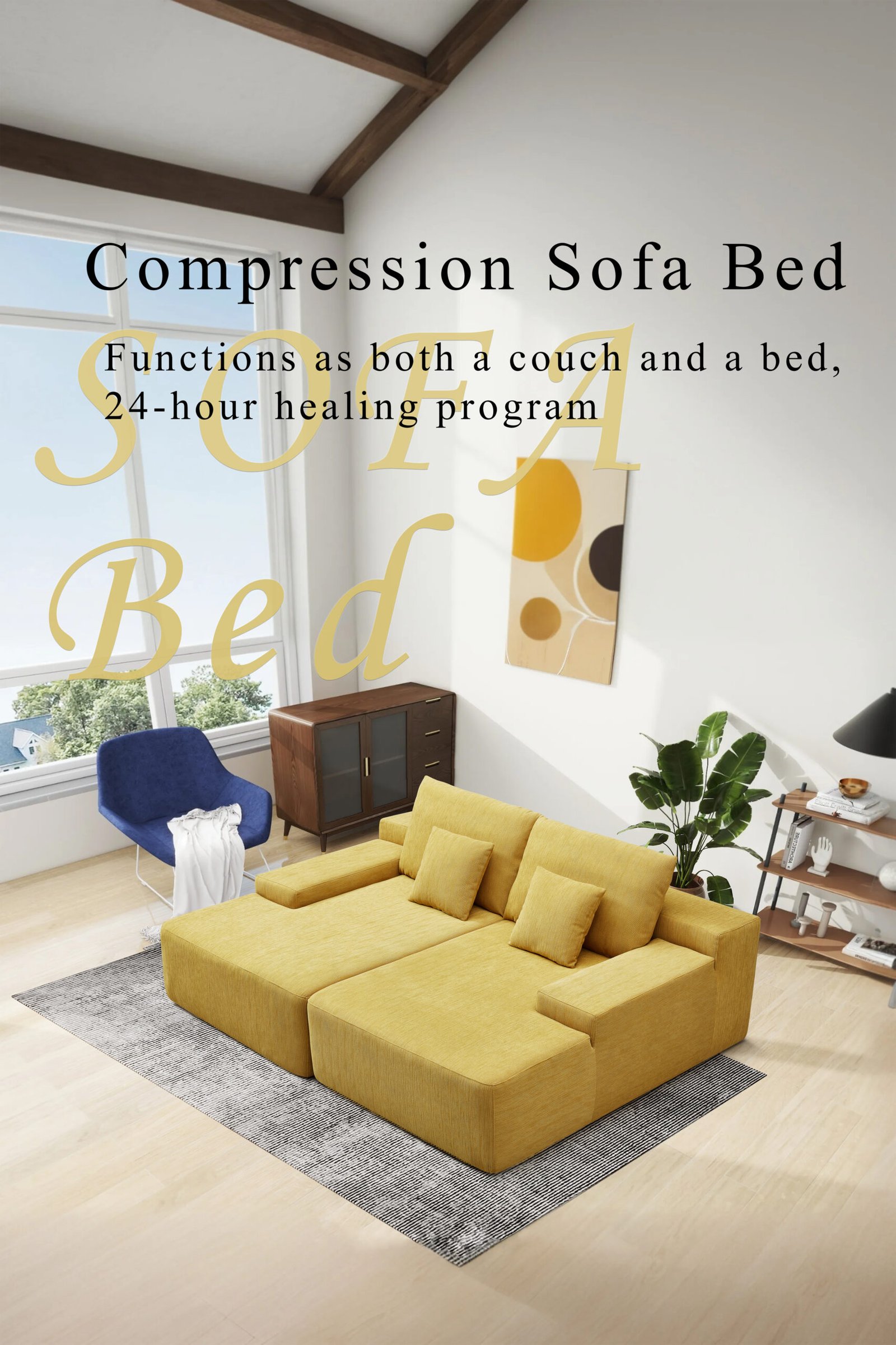

Can compressed sofas be pre-stocked?

Yes—some suppliers maintain ready-to-ship stock for fast-moving SKUs.

These models are usually neutral in style and color, designed for quick dispatch.

Benefits:

- 3–10 day delivery

- Minimal MOQ

- Ideal for small dropshippers or urgent restocks

Drawbacks:

- Limited design and fabric options

- Less room for branding or customization

Ask your supplier if they offer “hot-sale” ready models and set up a replenishment system.

How does peak season affect lead times?

From September to December, factory schedules are tight.

Q4 is peak season due to holiday demand, Black Friday, and Chinese New Year stock-ups.

What to expect:

- Lead times jump from 30–40 to 50–70 days

- Production slots book up fast

- Freight costs surge

- Risk of stockouts increases

If you rely on seasonal promotions, plan your inventory 3 months early, or work with suppliers offering guaranteed delivery slots.

How do quality control and inspections affect lead time?

Inspections protect your business—but they also add time.

Factories that follow ISO or third-party QC protocols usually spend 3–5 days on inspection, testing, and final approval.

If issues arise (like stitching defects or packaging damage), sofas may need rework or re-compression, extending timelines by another week.

To speed things up:

- Approve a pre-shipment sample early

- Use standardized QC checklists

- Communicate tolerances clearly

- Work with suppliers who welcome third-party audits

How can communication improve lead time predictability?

Many lead time issues come down to poor coordination.

Clear, consistent communication reduces mistakes, accelerates scheduling, and allows suppliers to allocate resources better.

Tips:

- Share forecasted volumes at least 1–2 months ahead

- Use shared calendars or production trackers

- Confirm deadlines with written PO terms

- Avoid last-minute changes to fabric or packaging

Suppliers love clients who communicate like partners.

Conclusion

Compressed sofa suppliers generally operate on a 30–60 day lead time cycle, shaped by material flow, production capacity, inspection time, and global shipping dynamics. With clear planning and proactive communication, you can manage lead time variability and deliver better value to your end customers.