In the evolving landscape of furniture packaging, compressed sofa packaging has become a popular method to reduce shipping costs and improve logistics efficiency. A critical aspect of this packaging method is the closure system, which ensures the sofa remains securely compressed and protected during transportation and storage. This article explores the common closure types used in compressed sofa packaging, their features, advantages, and how to select the most appropriate closure for your product. We will also include a detailed comparison table to help manufacturers and distributors make informed decisions.

Understanding Compressed Sofa Packaging

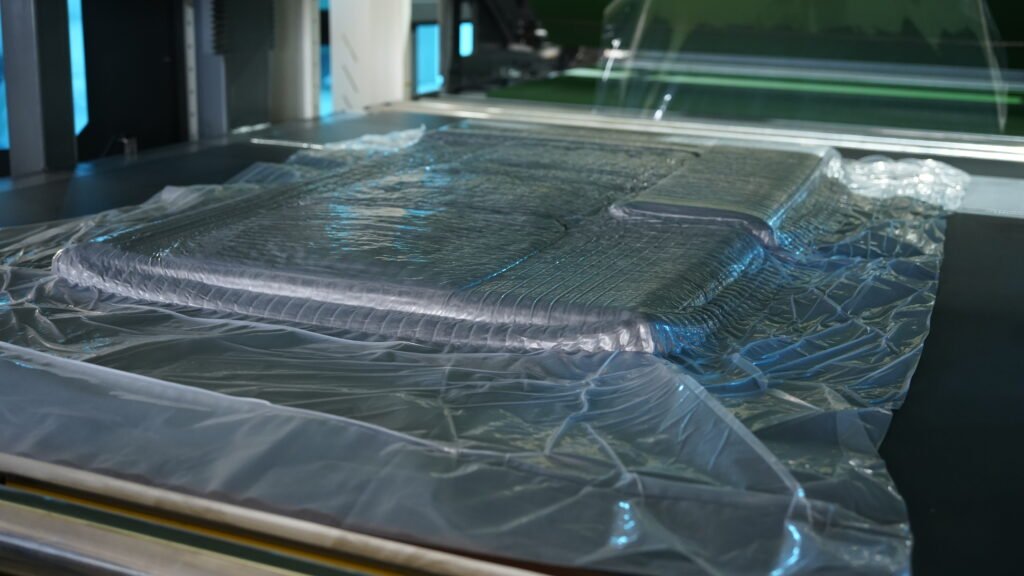

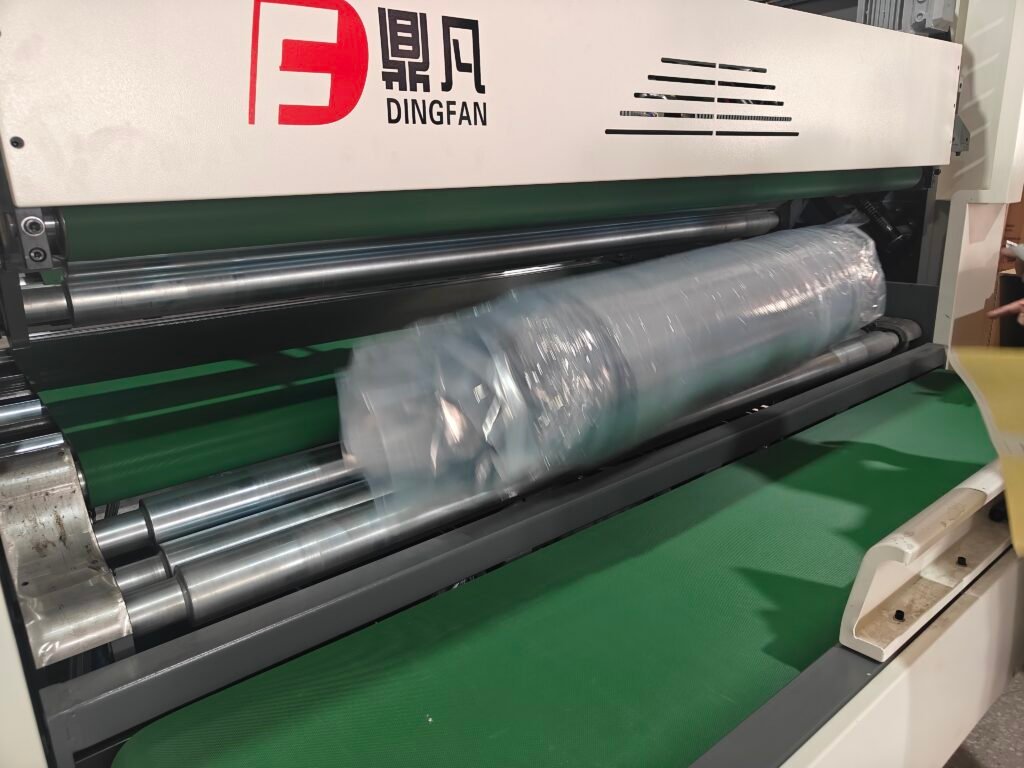

Compressed sofa packaging involves compressing the sofa components—such as cushions and frames—into a compact form, often vacuum-sealed or tightly wrapped, to minimize volume. This packaging method not only reduces shipping and storage costs but also protects the product from dust, moisture, and damage.

The closure system in compressed sofa packaging plays a vital role in maintaining the compressed state and ensuring the packaging integrity throughout the supply chain. The choice of closure affects ease of handling, protection level, and customer experience upon unboxing.

Common Closure Types in Compressed Sofa Packaging

1. Zipper Closures

Zipper closures are widely used in compressed furniture packaging due to their convenience and reusability. They consist of interlocking plastic or metal teeth that can be easily opened and closed multiple times.

- Advantages: Easy to use, reusable, provides a secure seal, and allows partial opening for inspection without fully unpacking.

- Applications: Commonly used in vacuum-sealed sofa covers or fabric bags that hold compressed cushions.

2. Heat Seal Closures

Heat sealing involves melting and bonding plastic layers to create an airtight and tamper-evident closure.

- Advantages: Provides a strong, airtight seal that protects against moisture and contaminants, ideal for long-term storage.

- Limitations: Non-reusable; requires cutting to open, which may reduce convenience for consumers.

- Applications: Used in vacuum packaging films or shrink wraps for compressed sofas.

3. Adhesive Tape Closures

Adhesive tapes, including pressure-sensitive tapes or gummed tapes, are often used to seal packaging bags or boxes.

- Advantages: Cost-effective, easy to apply, and compatible with various packaging materials.

- Limitations: May lose adhesion under extreme conditions; not reusable.

- Applications: Used for sealing cardboard boxes or plastic bags containing compressed sofa parts.

4. Snap Lock or Click Lock Closures

These closures use interlocking plastic components that snap together to secure the packaging.

- Advantages: Reusable, secure, and can be operated without tools.

- Applications: Used in rigid plastic packaging or reusable fabric covers.

5. Velcro Closures

Velcro strips provide an easy-to-use, adjustable closure option.

- Advantages: Reusable, adjustable tightness, and user-friendly.

- Limitations: May wear out over time and attract dust.

- Applications: Used in fabric sofa covers or protective wraps.

6. Drawstring Closures

Drawstrings allow tightening of fabric bags or covers by pulling cords.

- Advantages: Simple, adjustable, and reusable.

- Limitations: May not provide airtight sealing.

- Applications: Used in fabric compression bags.

Comparison Table of Common Closure Types in Compressed Sofa Packaging

| Closure Type | Seal Strength | Reusability | Ease of Use | Protection Level | Typical Applications | Cost |

|---|---|---|---|---|---|---|

| Zipper Closure | Medium | High | Very Easy | Moderate | Vacuum bags, fabric covers | Moderate |

| Heat Seal Closure | Very High | No | Moderate (one-time) | Excellent (airtight) | Vacuum films, shrink wraps | Higher |

| Adhesive Tape | Medium | No | Easy | Moderate | Cardboard boxes, plastic bags | Low |

| Snap Lock Closure | High | Yes | Easy | High | Rigid plastic packaging | Moderate-High |

| Velcro Closure | Medium | Yes | Very Easy | Moderate | Fabric covers, protective wraps | Moderate |

| Drawstring Closure | Low-Medium | Yes | Easy | Low-Moderate | Fabric compression bags | Low |

Factors to Consider When Choosing Closure Types for Compressed Sofa Packaging

- Product Protection Needs: For long-distance shipping or storage in humid environments, closures offering airtight and moisture-resistant seals, like heat seals or zipper closures, are preferable.

- Reusability: If customers are expected to reuse the packaging, closures like zippers, Velcro, or snap locks provide convenience and sustainability.

- Cost Efficiency: Adhesive tapes and drawstrings are cost-effective but may compromise on protection and reusability.

- Ease of Handling: Closures that are easy to open and close improve customer experience and reduce damage risk during unpacking.

- Environmental Impact: Consider closures made from recyclable or reusable materials to align with sustainability goals.

Conclusion

Choosing the right closure type for compressed sofa packaging is essential to ensure product integrity, ease of handling, and customer satisfaction. Zipper closures and heat seals are among the most common due to their balance of protection and convenience. However, factors such as cost, reusability, and environmental considerations also influence the choice. By understanding the features and applications of each closure type, manufacturers and distributors can optimize their packaging solutions to meet market demands effectively.

For specialized compressed sofa packaging solutions and expert advice on closure systems, visit our company website at https://modular-sofas.com/.

This article has provided a comprehensive overview of common closure types used in compressed sofa packaging, supported by a detailed comparison table to guide your packaging decisions. If you require further customization or technical specifications, our team is ready to assist you.