Introduction

In today’s highly competitive furniture industry, efficient packaging solutions are essential for manufacturers, wholesalers, and distributors. Compress sofa packaging has become a revolutionary method that significantly reduces shipping costs and storage space while ensuring product protection. This guide is designed specifically for B2B stakeholders—including sofa manufacturers, packaging suppliers, furniture distributors, and logistics providers—looking to optimize their compress sofa packaging strategies in 2024.

What Is Compress Sofa Packaging?

Compress sofa packaging refers to the process of vacuum compressing sofas to reduce their volume for transportation and storage. By tightly packing sofas into compact cartons, businesses can lower freight costs and maximize warehouse space utilization.

For B2B clients, such as bulk buyers, furniture wholesalers, and retailers, this packaging method offers substantial cost savings and simplifies inventory management. Packaging suppliers can provide customized compression packaging solutions tailored to the specific dimensions and materials of sofas.

Key Benefits of Compress Sofa Packaging for B2B Clients

One of the primary advantages of compress sofa packaging is space efficiency. Compressed sofas occupy considerably less volume compared to traditionally packaged sofas, allowing more units to be shipped per container and reducing warehousing expenses.

Cost reduction is another major benefit, as smaller package sizes lead to lower freight charges. From a sustainability perspective, using less packaging material and minimizing transportation volume aligns with corporate environmental goals.

Additionally, advanced cushioning materials combined with vacuum sealing protect sofas from moisture, dust, and deformation during transit. The modular packaging design also facilitates easy assembly and reconfiguration upon delivery.

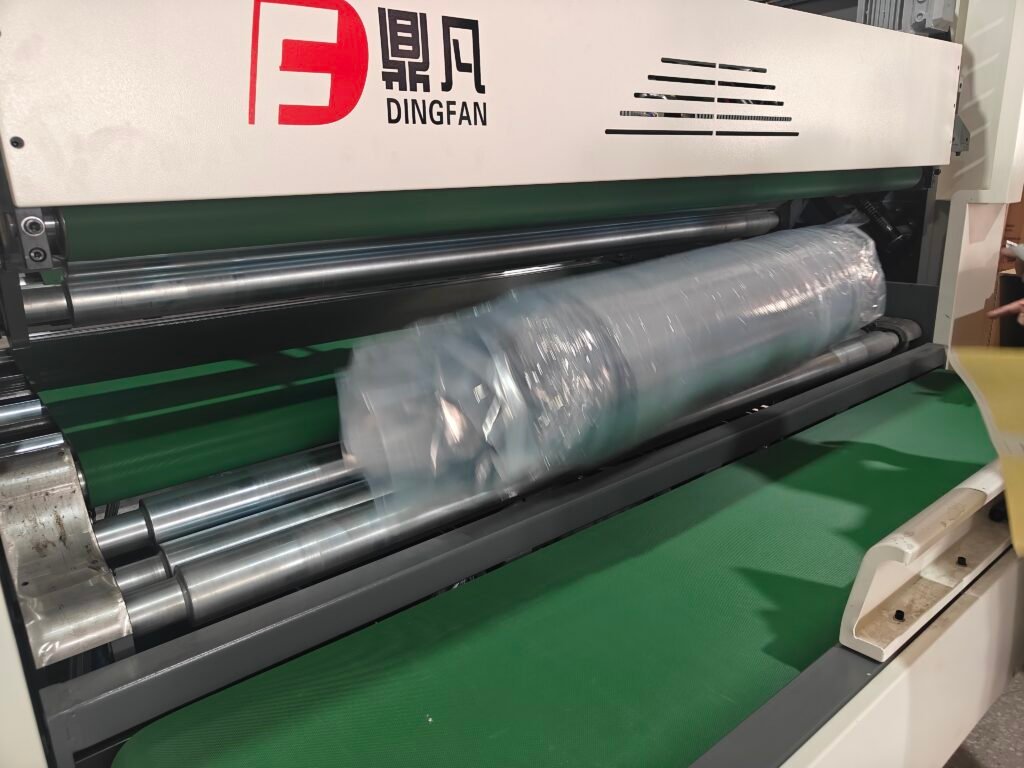

Materials and Technologies Used in Compress Sofa Packaging

Common materials include durable, puncture-resistant vacuum-sealable plastic films, high-density foam inserts for cushioning, and corrugated fiberboard cartons custom-sized to the compressed sofa dimensions. Industrial vacuum sealers and custom tooling ensure consistent packaging quality.

Packaging Design Considerations for Compress Sofas

Effective packaging design must balance product protection, ease of handling, and brand presentation. Primary packaging consists of the compressed sofa wrapped in vacuum film with protective foam layers. Secondary packaging involves corrugated cartons precisely sized to the compressed dimensions. Tertiary packaging includes pallets and shrink wrap for bulk shipments to distributors or retailers.

For B2B customers, packaging should enable efficient unpacking and assembly while minimizing the risk of damage during transportation.

Customization and Branding Opportunities in Compress Sofa Packaging

Custom printing on cartons—such as logos, product details, and handling instructions—helps reinforce brand identity. Using recyclable or biodegradable materials appeals to environmentally conscious business buyers.

Clear labeling with SKU numbers, batch codes, and assembly guides improves supply chain traceability and operational efficiency.

Logistics and Supply Chain Impact

Compressed packaging reduces loading and unloading times and optimizes warehouse space utilization. Shipping efficiency is improved by increasing the number of units per container, which lowers per-unit transportation costs.

Inventory management is streamlined, making stock handling easier for distributors and retailers.

Choosing the Right Packaging Supplier for Compress Sofas

When selecting a packaging supplier, look for companies experienced in custom packaging solutions for furniture. Verify their capabilities in vacuum packaging technology and corrugated carton manufacturing.

Prioritize suppliers offering bulk order discounts, fast lead times, and environmentally friendly materials. Relevant keywords for sourcing suppliers include “compress sofa packaging supplier,” “furniture packaging manufacturer,” “bulk sofa packaging solutions,” and “custom corrugated cartons for sofas.”

Future Trends in Compress Sofa Packaging

The adoption of smart packaging technologies—such as QR codes for assembly instructions and product authentication—is increasing. The development of biodegradable compression films is gaining momentum to reduce environmental impact.

Modular packaging designs that support multiple sofa configurations will continue to enhance flexibility and customer satisfaction.

Conclusion

Compress sofa packaging is transforming the furniture supply chain by delivering cost-effective, space-saving, and protective solutions tailored for B2B clients. By partnering with specialized packaging suppliers and leveraging innovative materials and designs, manufacturers and distributors can improve operational efficiency and meet growing market demands in 2024 and beyond.