Tired of saggy cushions that flatten in weeks? High-resilience foam might be the upgrade your sofa—and your back—deserves.

High-resilience foam uses advanced polyurethane chemistry to provide long-lasting support, excellent elasticity, and superior comfort in sofas.

Let’s unpack what makes this material the gold standard in sofa construction—and why it's a must-know for furniture buyers.

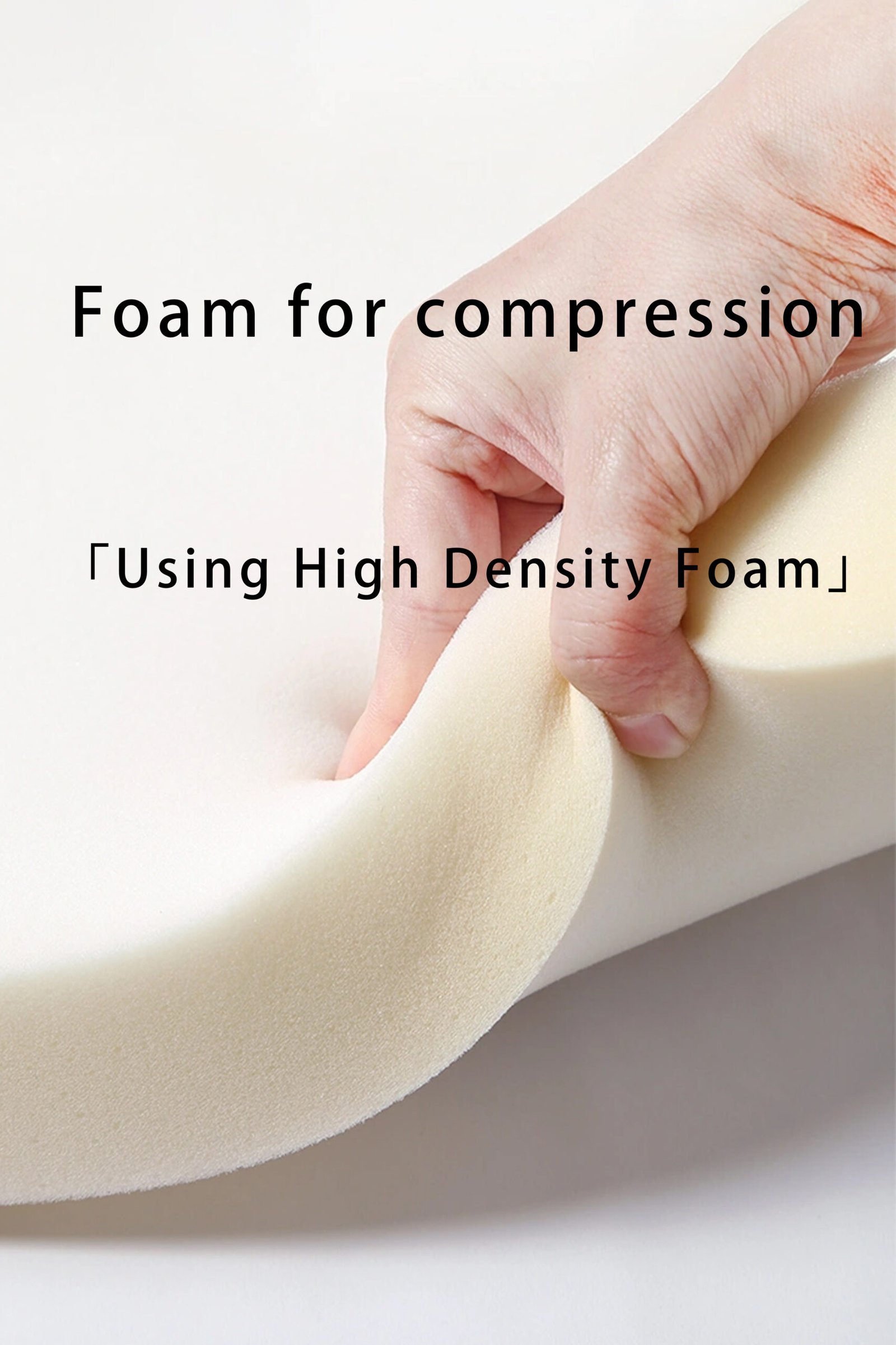

What is high-resilience (HR) foam?

Ever sat on a cushion that bounces back immediately when you get up? That’s the HR foam effect.

High-resilience foam is a type of polyurethane foam with a unique open-cell structure that offers exceptional spring-back, durability, and support.

Unlike basic foam, HR foam is made with:

- Higher-quality polyols: for elasticity and strength

- Precise chemical ratios: for consistent cell formation

- Additives like surfactants and catalysts: to optimize resilience and lifespan

💡 Think of it like memory foam’s bouncier, longer-lasting cousin—but with less sink and more support.

How is HR foam made?

HR foam manufacturing is a science-led process with multiple stages:

- Mixing the ingredients: Polyols + diisocyanates + additives

- Chemical reaction: A controlled exothermic reaction creates the foam

- Foaming and expansion: The mixture expands with gas formation

- Curing: The foam sets and strengthens over hours or days

- Cutting and shaping: Final forms are sliced for sofa use

This detailed process ensures:

- Uniform cell structure

- High elasticity

- Stable density and shape

⚙️ Good HR foam = tight quality control from chemistry to cutting table.

What makes HR foam different from other foams?

Let’s compare with the most common options:

| Foam Type | Density | Bounce-back | Comfort Level | Lifespan |

|---|---|---|---|---|

| Standard PU Foam | Low–Medium | Poor | Basic | 1–2 yrs |

| Memory Foam | Medium–High | Slow | Sinking feel | 3–5 yrs |

| HR Foam | Medium–High | Excellent | Responsive | 5–10 yrs |

🛋️ HR foam blends the support of memory foam with the responsiveness of latex—perfect for active seating like sofas.

How does HR foam improve comfort?

Comfort isn't just about softness. It's about pressure distribution, support, and breathability.

High-resilience foam excels by adapting to your body while holding its shape over time.

Here’s how:

- Conforms to body weight—but not too much

- Evenly distributes pressure—no pressure points

- Bounces back fast—no lingering indentations

- Promotes airflow—thanks to open-cell structure

✅ Result: A “just-right” feel that supports the back, hips, and shoulders without sagging.

Why does HR foam last longer?

It’s all about structure.

HR foam has a higher internal strength than regular polyurethane foam. That means:

- Fewer broken cells over time

- Less permanent sagging

- Better shape retention

- Consistent feel even after years of use

🏆 Sofas made with HR foam can last up to 10 years with daily use.

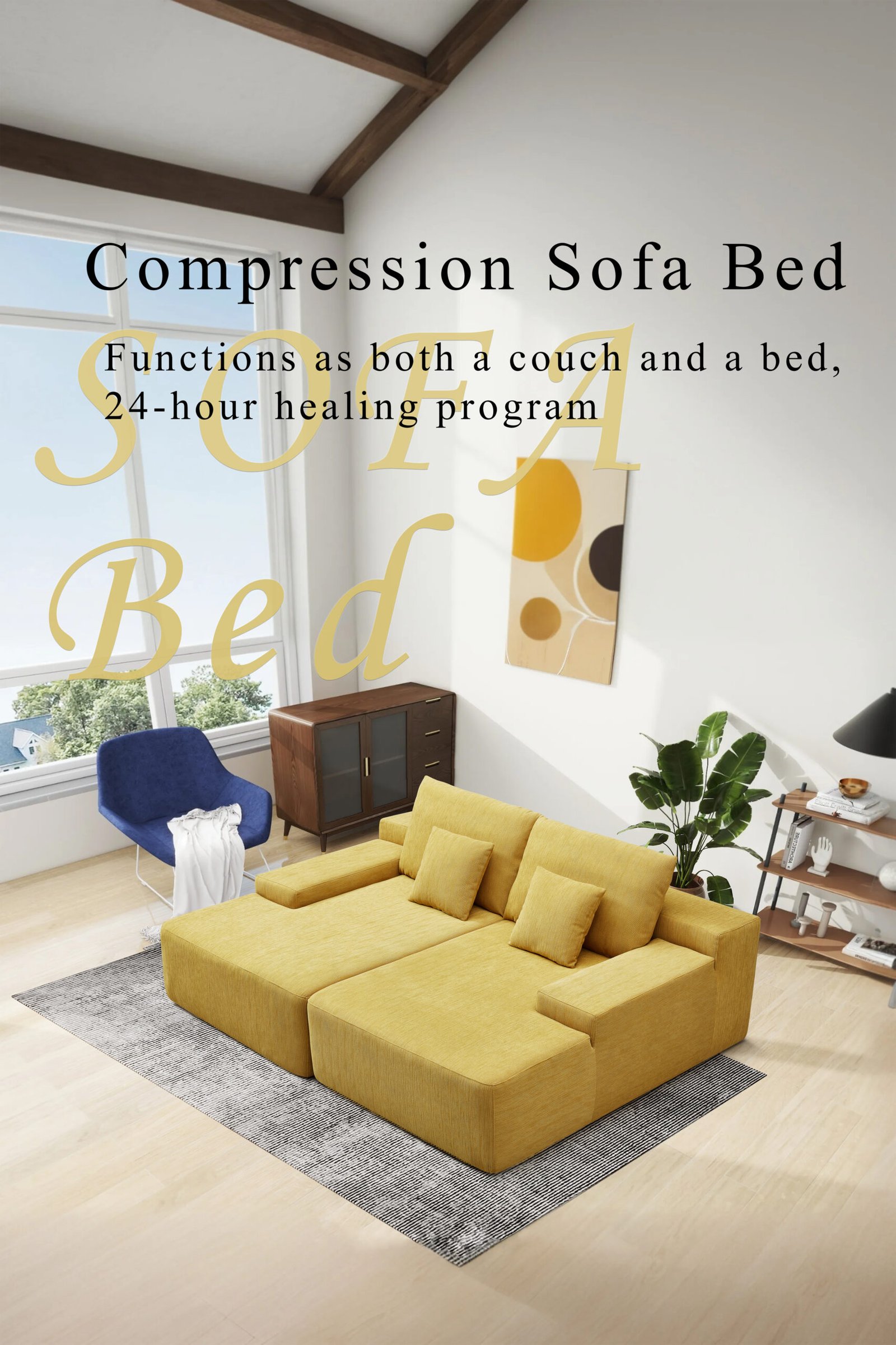

Is HR foam good for compressed sofas?

Yes—and here’s why.

Compressed sofas need foam that can be flattened, shipped, then expand back without damage. HR foam is ideal.

- Resilient under compression

- Returns to shape fast after unboxing

- Resists deformation and wrinkles

- Handles temperature and humidity changes well

🚚 That’s why top compressed sofa brands often rely on HR foam—it’s built to bounce back.

Is HR foam eco-friendly?

Traditional polyurethane foams aren’t biodegradable—but the industry is evolving.

Some eco-conscious improvements include:

- Bio-based polyols (e.g., from soy or castor oil)

- CertiPUR-US® certified foam: low-VOC and no harmful chemicals

- Foam recycling programs to reduce landfill waste

🌍 If sustainability matters, ask your sofa supplier about foam certifications.

How can you tell if a sofa has HR foam?

It’s not always advertised up front—but you can ask.

Look for:

- CertiPUR-US® or HR foam label

- Density rating: HR foam usually 1.8 lb/ft³ and up

- High indentation load deflection (ILD) for firm, supportive feel

- Long warranty (5+ years) for seat cushions

🔍 If a sofa is suspiciously cheap, it’s probably not using HR foam.

Conclusion

High-resilience foam combines chemistry, engineering, and comfort science to deliver seating that lasts. If you're shopping for a compressed sofa—or any sofa, really—HR foam is a smart upgrade that your future self (and spine) will thank you for.