Want to reduce shipping emissions, cut packaging waste, and still offer stylish sofas? Compressed sofa suppliers are quietly reshaping the furniture industry—one vacuum-packed carton at a time.

Compressed sofa suppliers reduce environmental impact through efficient packaging, low-carbon logistics, eco-friendly materials, and circular design strategies that support sustainability at every stage of the supply chain.

Here's how they're doing it—and why it matters.

What makes compressed sofas environmentally friendly?

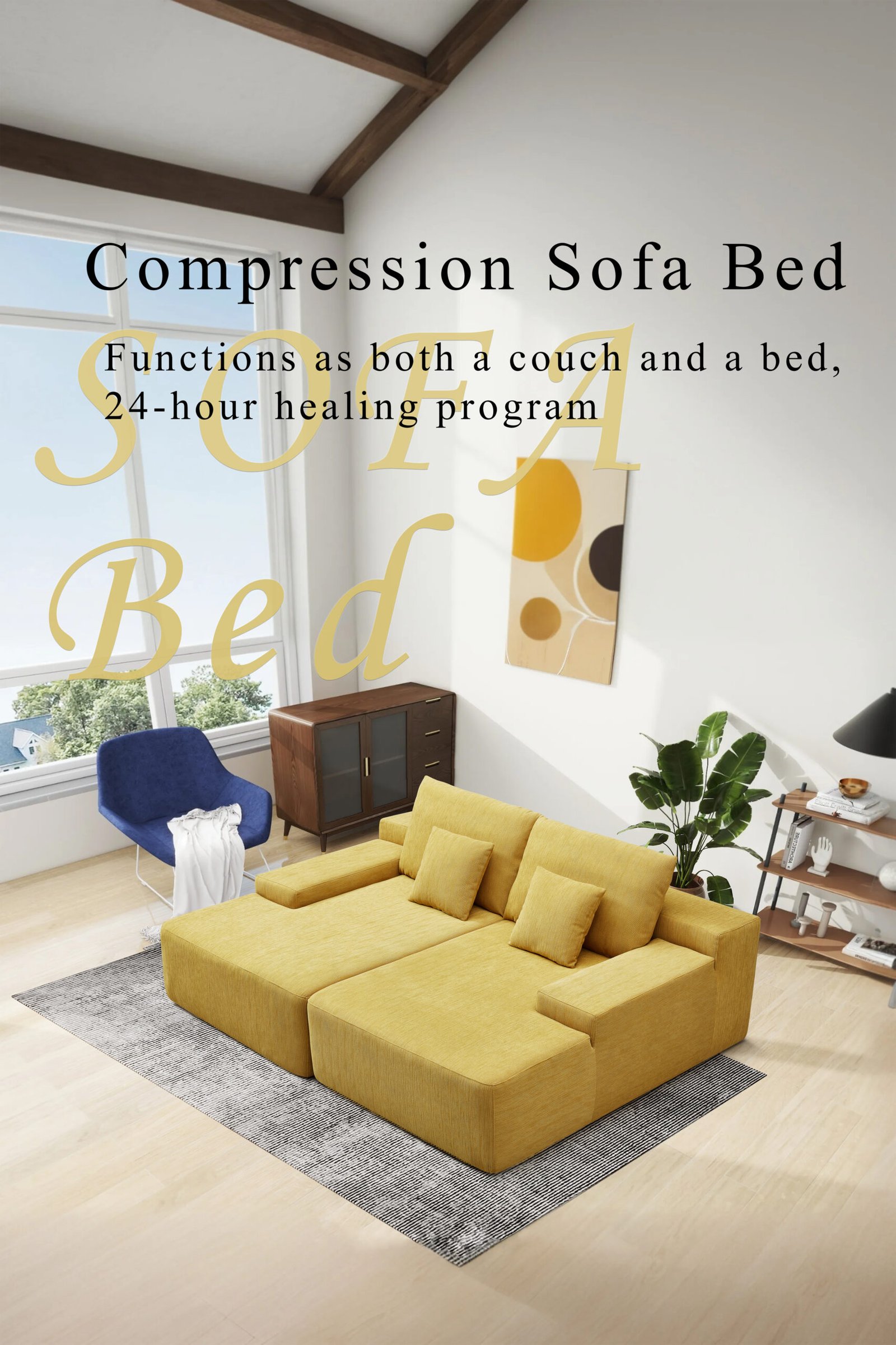

Sofas are typically heavy, bulky, and difficult to transport. Compressed sofas challenge all of that—and in doing so, they drastically shrink their environmental footprint.

Compressed sofas help the planet by using less packaging, requiring fewer shipping trips, and embracing energy-efficient production methods.

Here are the core reasons:

- Smaller volume = fewer trucks = fewer CO₂ emissions

- Vacuum packaging reduces need for bubble wrap or foam

- Lighter weight = less fuel used per unit

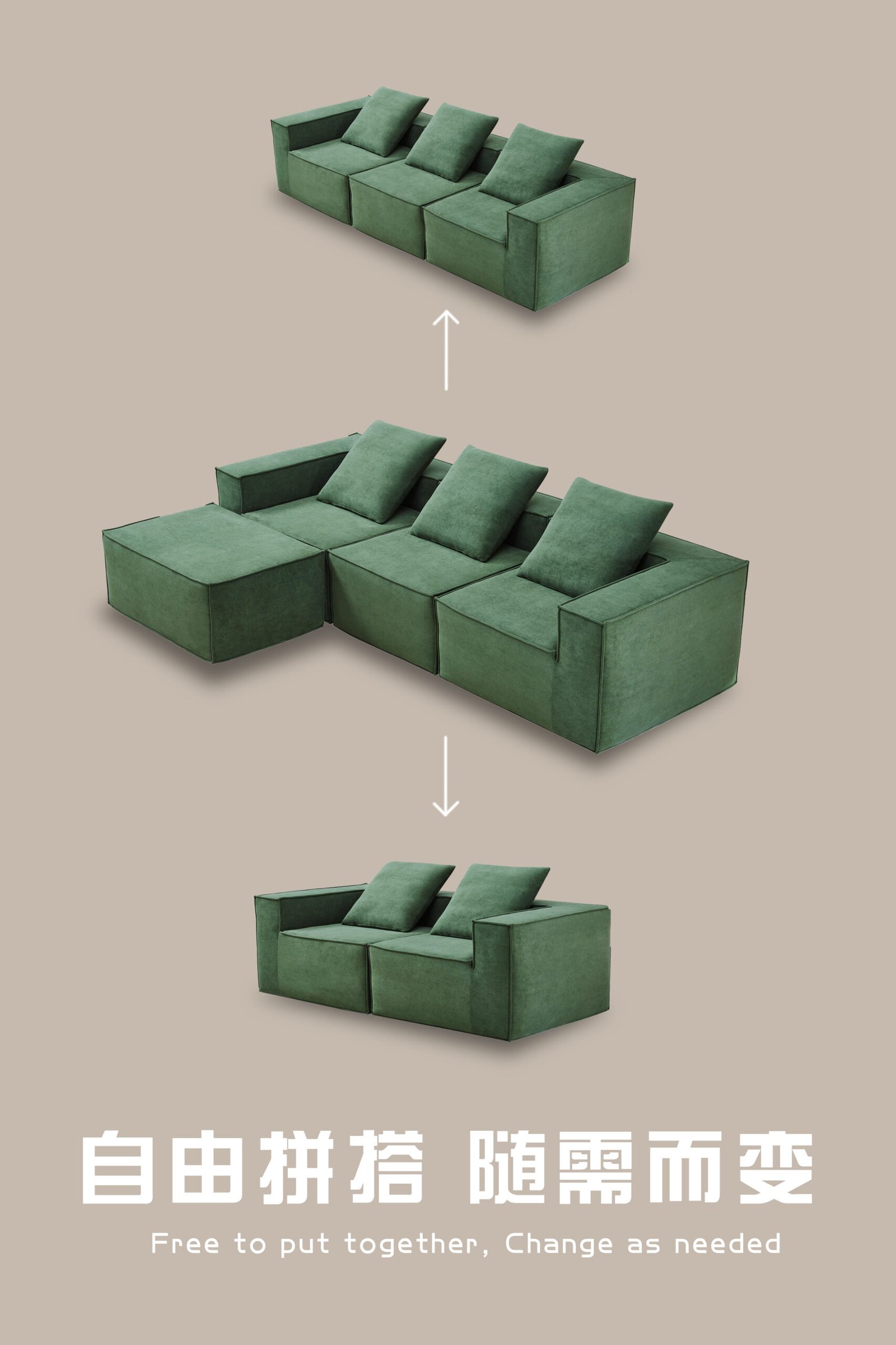

- Modular construction = less waste at end-of-life

These benefits aren't theoretical. They’re measurable.

How is the manufacturing process more sustainable?

The sustainability story begins in the factory.

Compressed sofa suppliers use lean production, automated machinery, and responsible sourcing to minimize waste and energy use.

Typical sustainability features in production:

- Low-emission adhesives

- Water-based finishes instead of solvent-based

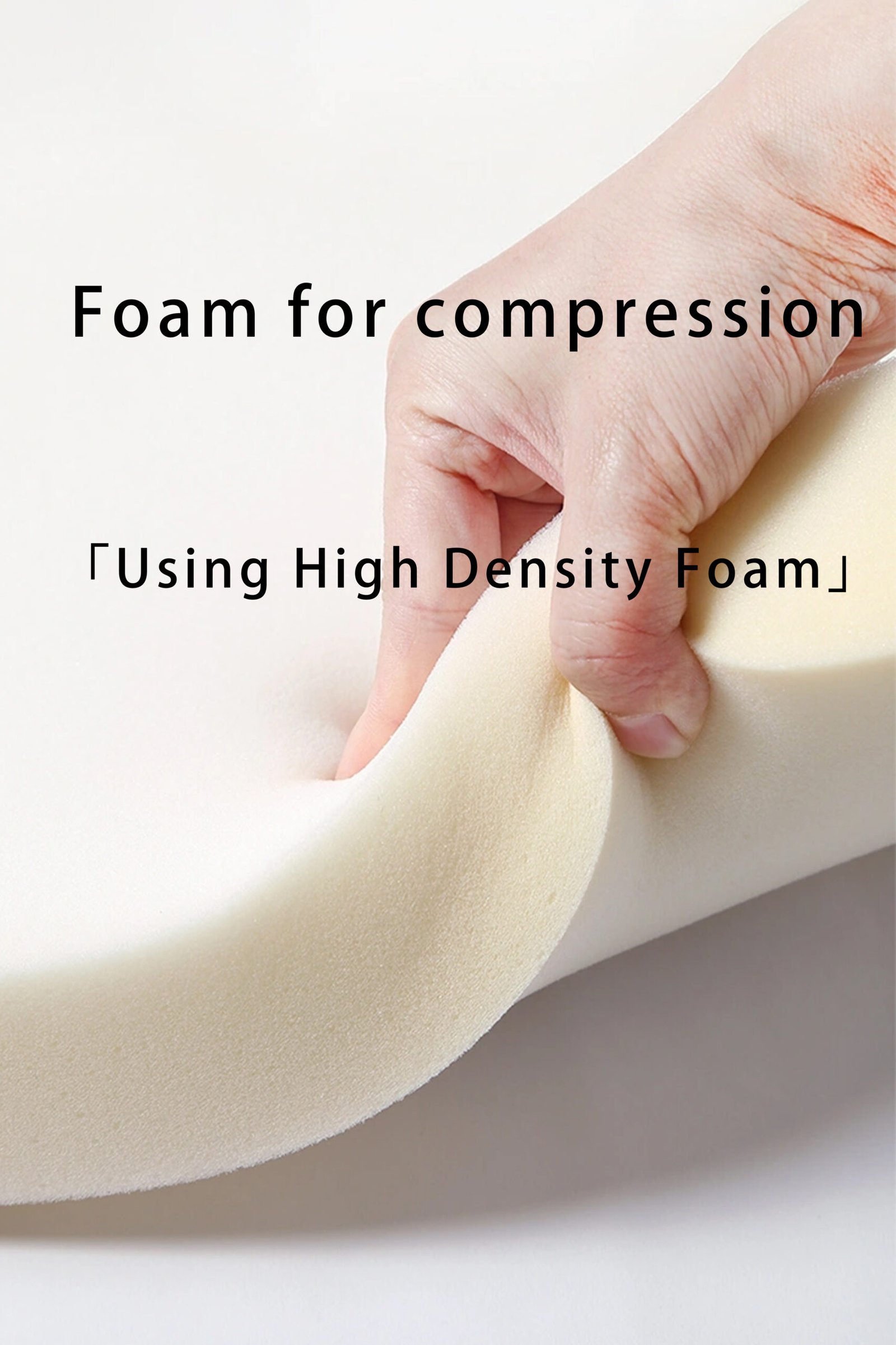

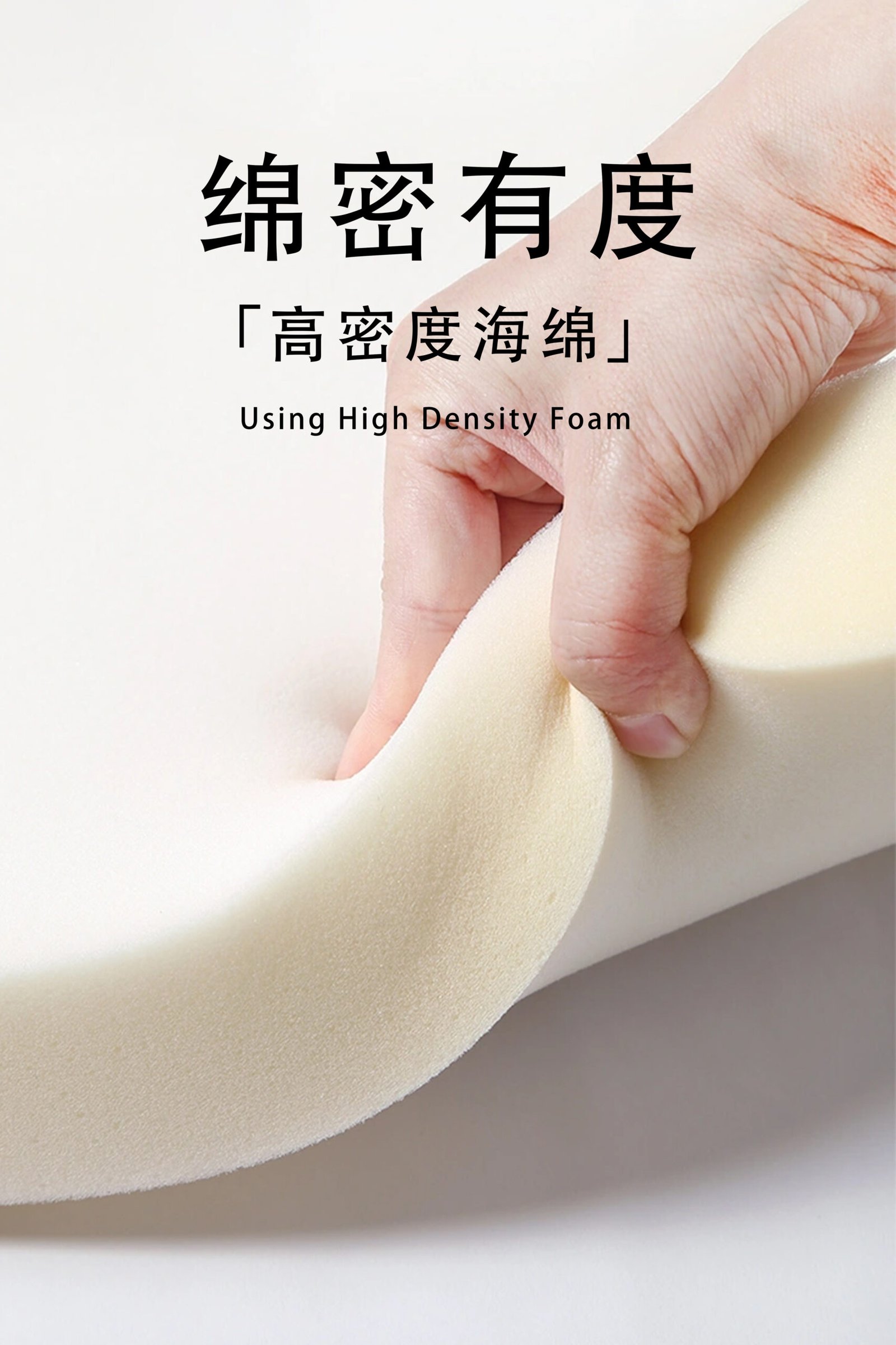

- High-density, recyclable polyurethane foam

- Sustainable wood sources (FSC-certified)

- Leftover fabric and foam scraps recycled or repurposed

And many factories are transitioning to solar-powered operations or other renewable energy to reduce grid dependency.

How does compression reduce carbon emissions?

Compression isn’t just a space-saving gimmick—it’s an environmental win.

Compressed sofas reduce their transport volume by up to 70%, which means fewer containers, fewer trucks, and significantly lower CO₂ emissions per unit.

Let’s look at the math:

| Transport Metric | Traditional Sofa | Compressed Sofa |

|---|---|---|

| Units per 40HQ container | 80–100 pcs | 220–280 pcs |

| Avg CO₂ emissions per sofa | 4.2 kg | 1.5–1.8 kg |

| Packaging material per unit | 2.5 kg | 0.8–1.2 kg |

In bulk logistics, even small changes like this create massive impact.

What about packaging waste?

Sofas used to come in layers of foam, cardboard, plastic, and wood framing. Not anymore.

Compressed sofa packaging uses recyclable materials and minimalist designs that reduce waste and improve recyclability.

Common materials used:

- Reinforced recycled cardboard (FSC-certified)

- LDPE shrink wrap (recyclable in many regions)

- No metal staples or wood frames

- Plant-based ink for labels and branding

Some brands now offer returnable or reusable packaging systems, especially for B2B deliveries.

Are compressed sofas built to last?

Yes—and durability is part of what makes them green.

Longer-lasting sofas reduce total environmental cost by requiring fewer replacements and minimizing landfill contribution.

Features that support longevity:

- High-resilience foam that retains shape after compression

- Strong modular frames made of birch or steel

- Washable and replaceable slipcovers

- Easy-to-repair components

Some suppliers even design their products for disassembly and recycling, supporting circular economy goals.

Can compressed sofas be recycled?

Absolutely, if they’re built the right way.

Many compressed sofa components are recyclable—including frames, foam, and fabric—especially when designed with circularity in mind.

Recyclable elements:

| Component | Material | Recyclability |

|---|---|---|

| Frame | Steel / plywood | High (steel), Medium (wood) |

| Foam | PU / memory foam | Limited but increasing (check local) |

| Upholstery | Polyester or linen blends | Depends on content |

| Packaging | Cardboard, LDPE, PET | Highly recyclable |

The key? Clear labeling and modular design that allows separation at end-of-life.

What sustainability certifications do suppliers follow?

Compressed sofa suppliers with green goals often follow international standards.

Common certifications:

- OEKO-TEX®: Safe textiles with no harmful chemicals

- FSC®: Responsibly harvested wood

- REACH: EU chemical compliance

- ISO 14001: Environmental management system

- GRS: Global Recycled Standard (for foam or fabric)

These certifications help suppliers prove their commitment—and help customers make informed choices.

How aware are consumers of these benefits?

Eco-friendly furniture used to be niche. That’s changing.

Buyers—especially younger and urban customers—now seek out sustainable furniture with low environmental impact and transparent supply chains.

They ask:

- Is this sofa made from recycled materials?

- Is it certified or labeled as eco-friendly?

- How long will it last before I need to replace it?

Suppliers who communicate their green practices clearly build trust and drive loyalty.

Are there real-world examples?

Yes—brands across Europe, North America, and Asia are now showcasing their sustainability practices.

For instance:

- A Canadian brand ships compressed sofas in fully recyclable packaging with net-zero shipping offsets

- A Chinese manufacturer uses solar power and FSC wood to fulfill bulk orders sustainably

- An EU distributor offers carbon-neutral shipping and modular recyclable sofas across 20+ countries

These case studies show the real impact compressed sofas are already making.

Conclusion

Compressed sofa suppliers are proving that convenience and sustainability can go hand in hand. From efficient shipping to recyclable packaging and circular design, these suppliers are leading the green furniture movement—one smartly packed sofa at a time.