One compresses for delivery. The other manufactures to order. But what really separates compressed sofa suppliers from OEM factories?

Compressed sofa suppliers focus on mass production, compression tech, and logistics efficiency, while OEM factories specialize in customization, brand services, and design execution.

If you’re sourcing sofas, knowing the difference can save you time, money—and headaches.

What exactly is a compressed sofa supplier?

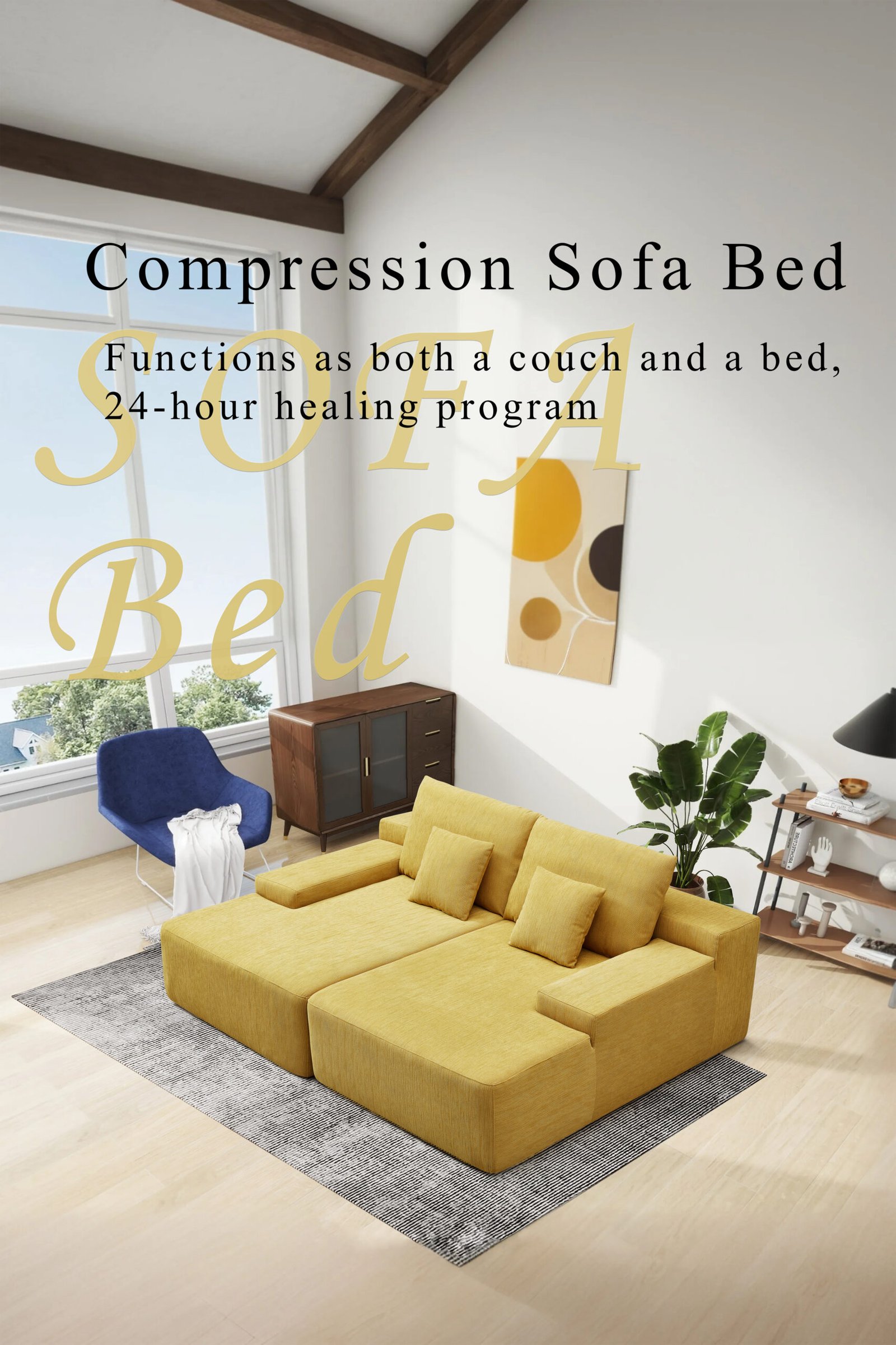

Ever seen a full-size sofa pop out of a small box?

That’s the magic of a compressed sofa supplier—they manufacture sofas designed for vacuum-packing and flat-pack logistics.

Their core features:

- Produce in bulk

- Use compression machinery

- Focus on shipping efficiency

- Sell under their own brand or white-label

Compressed sofa suppliers are ideal for e-commerce sellers and retailers who want ready-to-ship, space-saving furniture.

What does an OEM factory do?

OEM means "original equipment manufacturer"—but in furniture, it really means “custom builder behind the scenes.”

OEM factories make furniture based on a client's design, specs, and brand requirements.

Key roles:

- Don’t own their brand

- Produce under other brand names

- Follow buyer-provided drawings, materials, and sizes

- Flexible MOQs and custom processes

If you’re a brand or designer needing control over every detail—OEM is the route.

How do their production processes differ?

Compressed sofa suppliers: Efficiency first.

- Standardized models

- Fast assembly lines

- Compression packaging after QC

- Stock ready-to-ship inventory

OEM factories: Customization first.

- Make-to-order workflows

- Custom materials and parts

- Prototyping and sample approval

- Variable lead times depending on design

| Step | Compressed Sofa Supplier | OEM Factory |

|---|---|---|

| Production Model | Batch production | Make-to-order |

| Compression Required? | Yes | Usually no |

| Customization Level | Low to medium | High |

| Lead Time | Shorter | Longer (design-based) |

Who delivers better product quality?

That depends on what you value: speed or control.

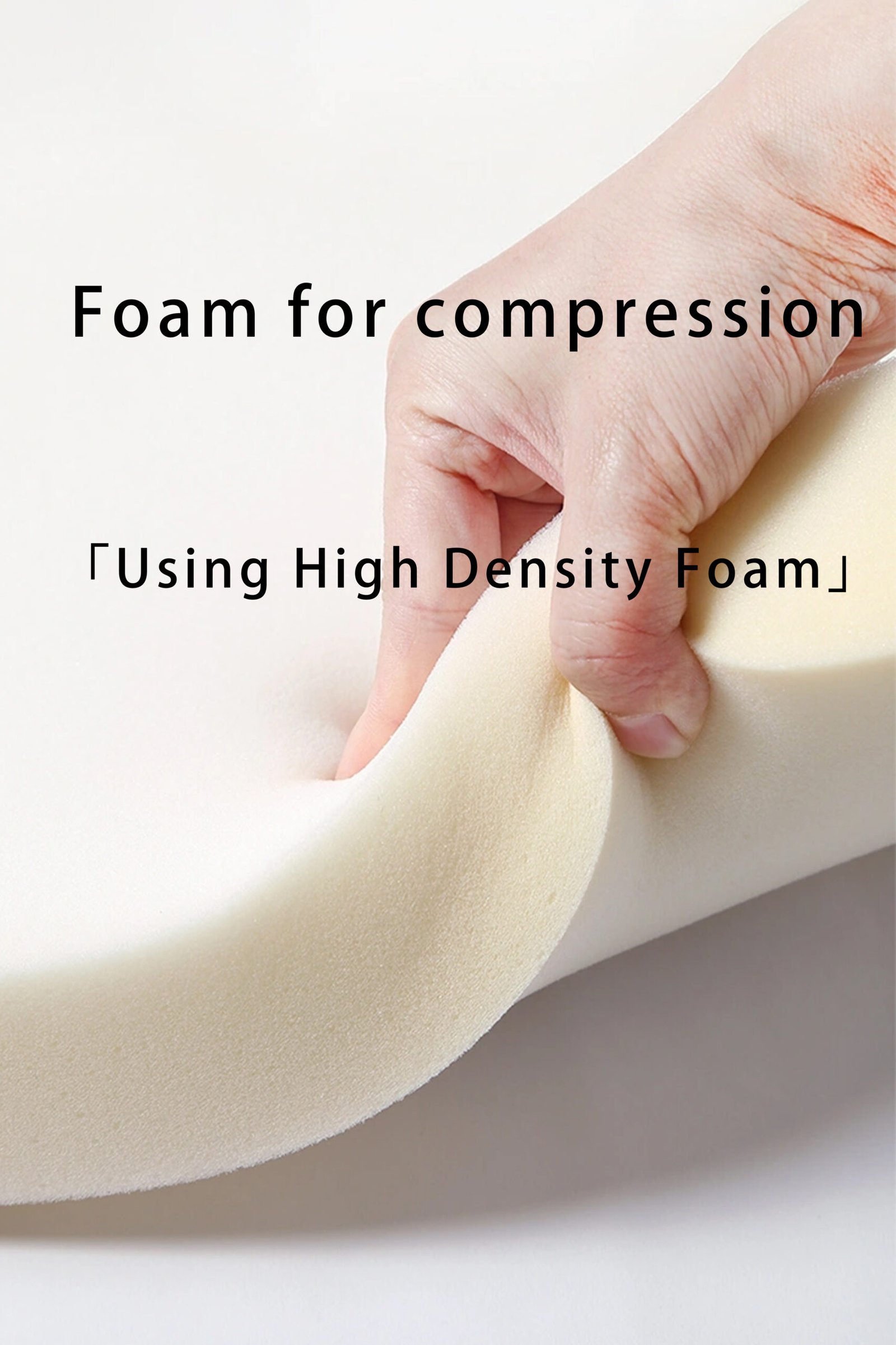

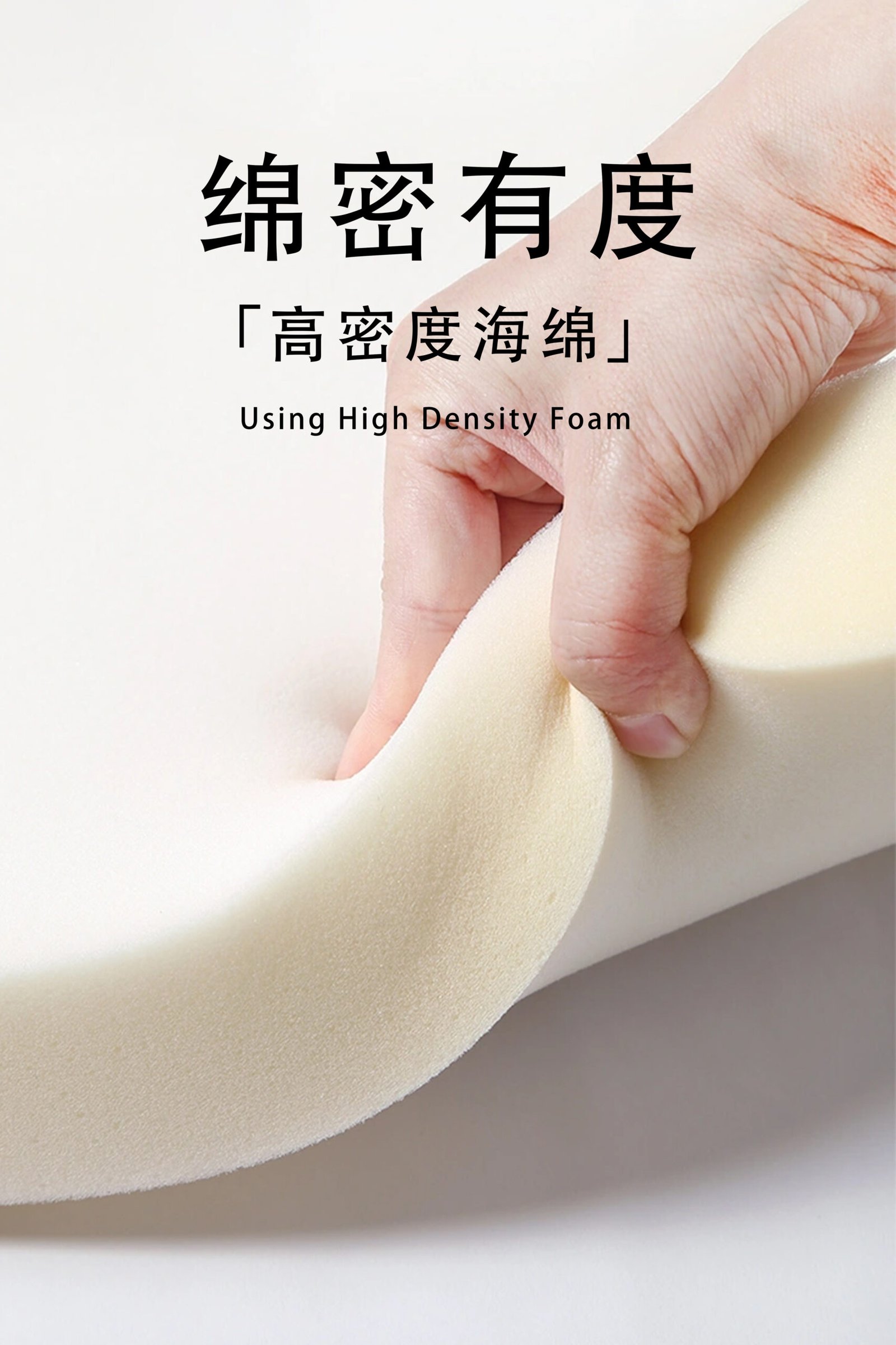

Compressed sofa suppliers focus on durability through compression cycles, standardized comfort, and efficient materials.

- Tested for compression resilience

- Designed for quick setup

- Quality tuned for logistics

OEM factories prioritize precision, high-grade materials, and brand-specific detailing.

- Fit-and-finish tailored to brand specs

- QA tied to client’s SOP

- Wider range of component options

Which one offers better design flexibility?

Need a sofa that matches your brand’s aesthetic exactly?

OEM factories are unmatched in flexibility.

They follow your blueprint, not theirs.

- You choose fabric, filling, frame

- They support new shapes, stitch types, custom mechanisms

- Custom logos, labels, packaging available

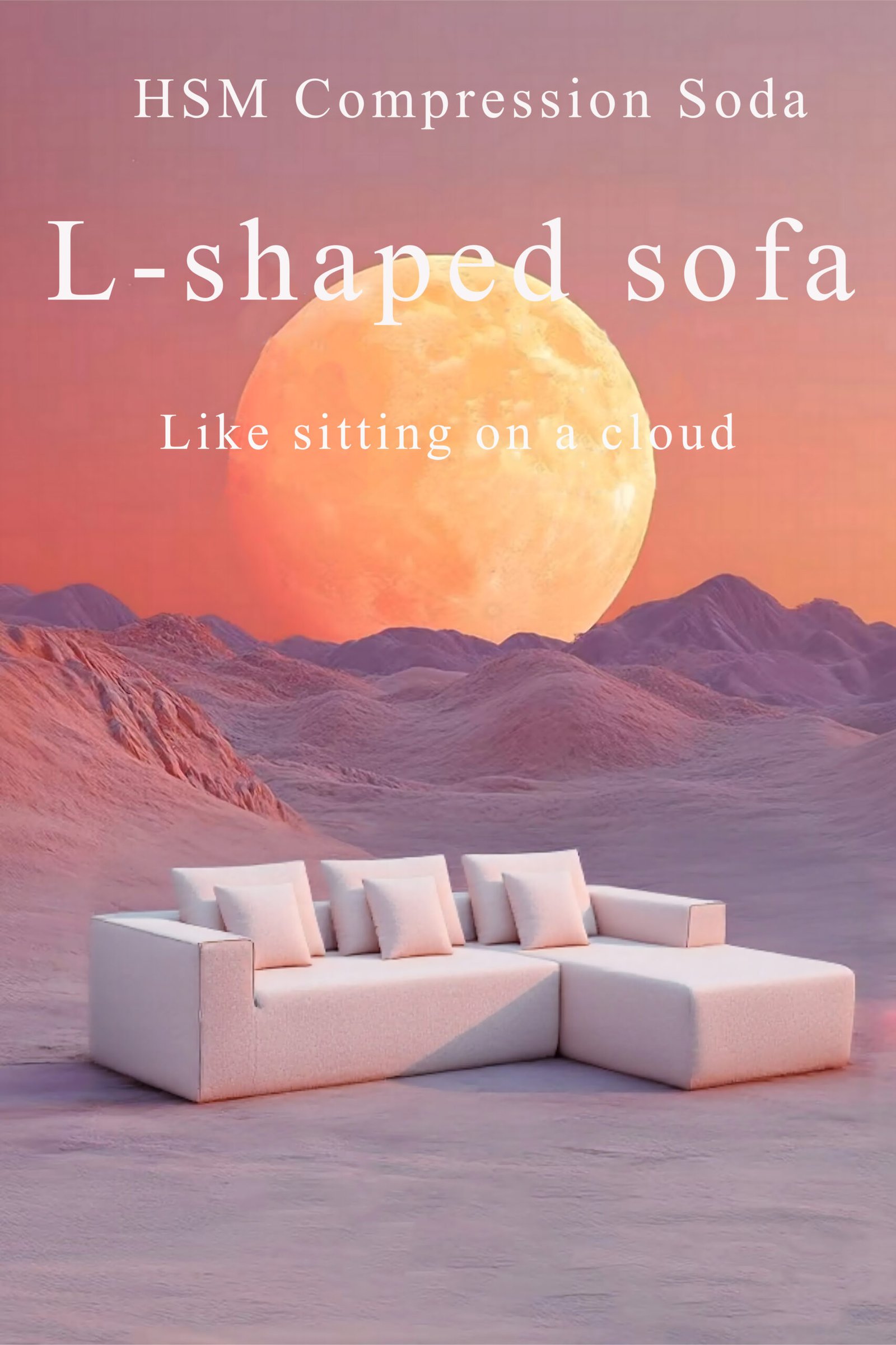

Compressed sofa suppliers innovate within limits.

They focus on:

- Compressible structures

- Lightweight modular frames

- Fold-flat backrests or pop-up cushions

Ideal if you want trendy, ready-to-ship designs—without going full custom.

What about pricing?

Compressed sofa suppliers win on unit price and shipping efficiency.

- Less packaging waste

- Lower freight cost per unit

- Ready to scale fast

OEM factories charge more—but you pay for precision.

- Custom R&D and sampling fees

- Longer production cycles

- Higher MOQs for rare materials

If you're building a brand, that premium may be worth it.

How do their logistics and services compare?

Compressed sofa suppliers are logistics pros.

- Products pack into 1/3 of traditional volume

- Often stock items for faster turnaround

- Ideal for cross-border e-commerce

OEM factories focus on long-term coordination.

- Factory-to-warehouse or factory-to-store shipping

- More touchpoints during production

- Requires deeper supply chain planning

If time-to-market matters? Compressed wins. If customization matters? OEM wins.

Who do they sell to?

Compressed sofa suppliers sell to:

- Amazon/FBA sellers

- Offline retailers with tight warehouse space

- Small brands looking to private label

OEM factories sell to:

- Established furniture brands

- Designers creating signature collections

- Wholesalers needing exclusive products

Which one is more sustainable?

Compressed sofa suppliers often use:

- Less packaging

- Lower transport emissions

- Recycled materials

OEM factories depend on the client’s specs—so sustainability is possible, but not guaranteed.

If you're eco-focused, compressed sofa suppliers may have a more built-in advantage due to shipping efficiency.

So which one should you choose?

Choose compressed sofa suppliers if you need:

- Fast delivery

- Affordable, trendy sofas

- Ready-to-sell inventory

Choose OEM factories if you want:

- Unique, custom-built products

- Full control over design

- A brand-defining product line

Conclusion

Compressed sofa suppliers and OEM factories serve different needs in the furniture ecosystem. One excels in scalable logistics. The other in tailored craftsmanship. The right one? Depends on what your business needs most.