Poor product quality leads to high return rates, bad reviews, and damaged brand trust—especially in e-commerce.

Compressed sofa suppliers must implement strict quality control standards across materials, production, compression, and delivery to ensure durability, safety, and consistency.

In this article, I’ll walk you through how we at HEYAN manage every step of sofa production to meet—and exceed—quality benchmarks.

Why are quality control standards critical for compressed sofas?

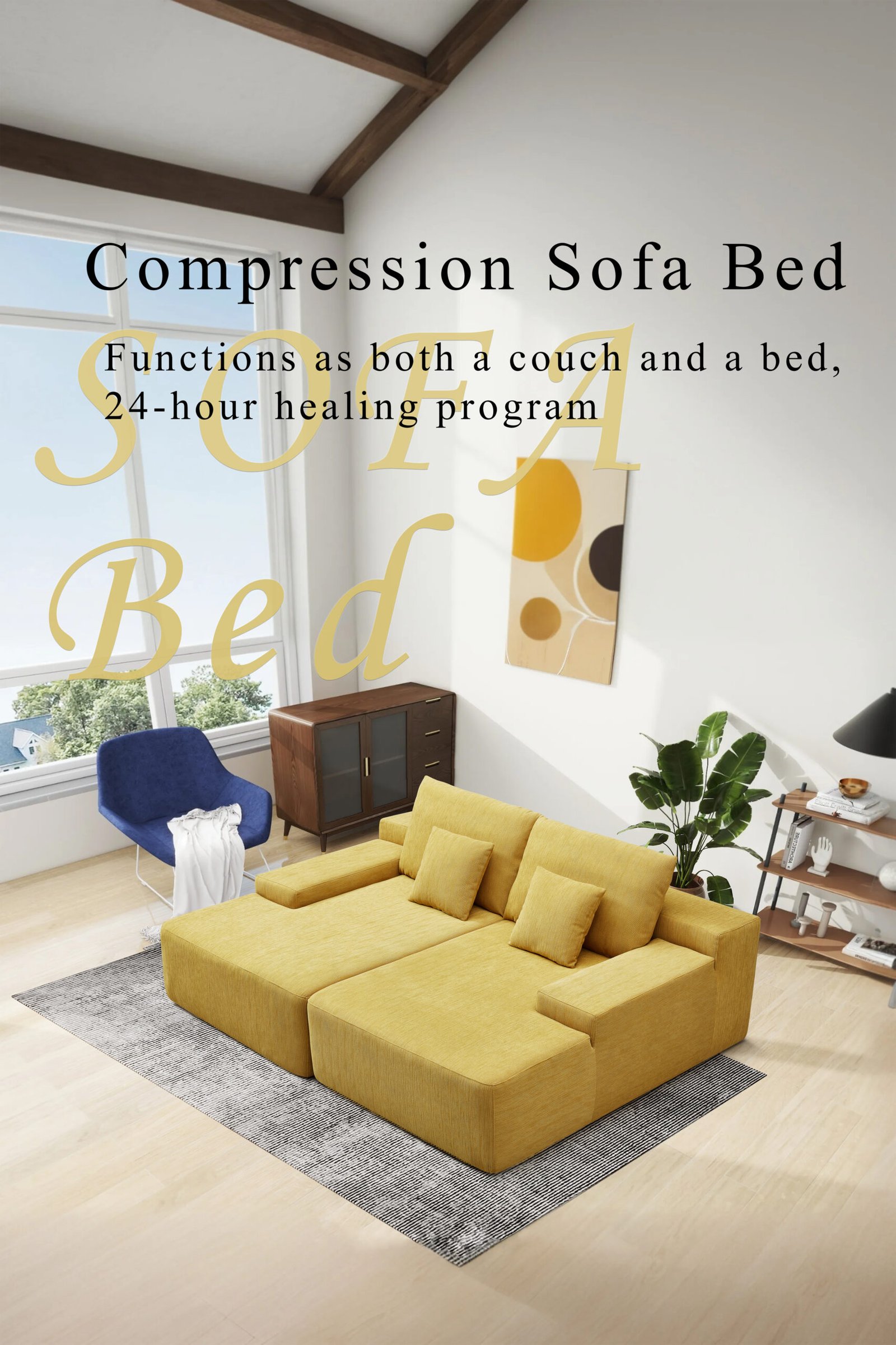

A compressed sofa isn’t just furniture—it’s an engineering product that must bounce back from intense packaging pressure and still look showroom-ready.

Without strict quality control, sofas can arrive misshapen, saggy, or broken—hurting your reputation and driving up costs.

At HSM, we treat quality control as part of our brand promise. It's how we’ve kept a 1.2% return rate over the last 3 years.

Key Impacts of Quality Control:

- Reduces refund & warranty claims

- Builds customer trust and brand loyalty

- Lowers repair and return logistics costs

- Improves resale value and repeat business

What raw materials are tested—and how?

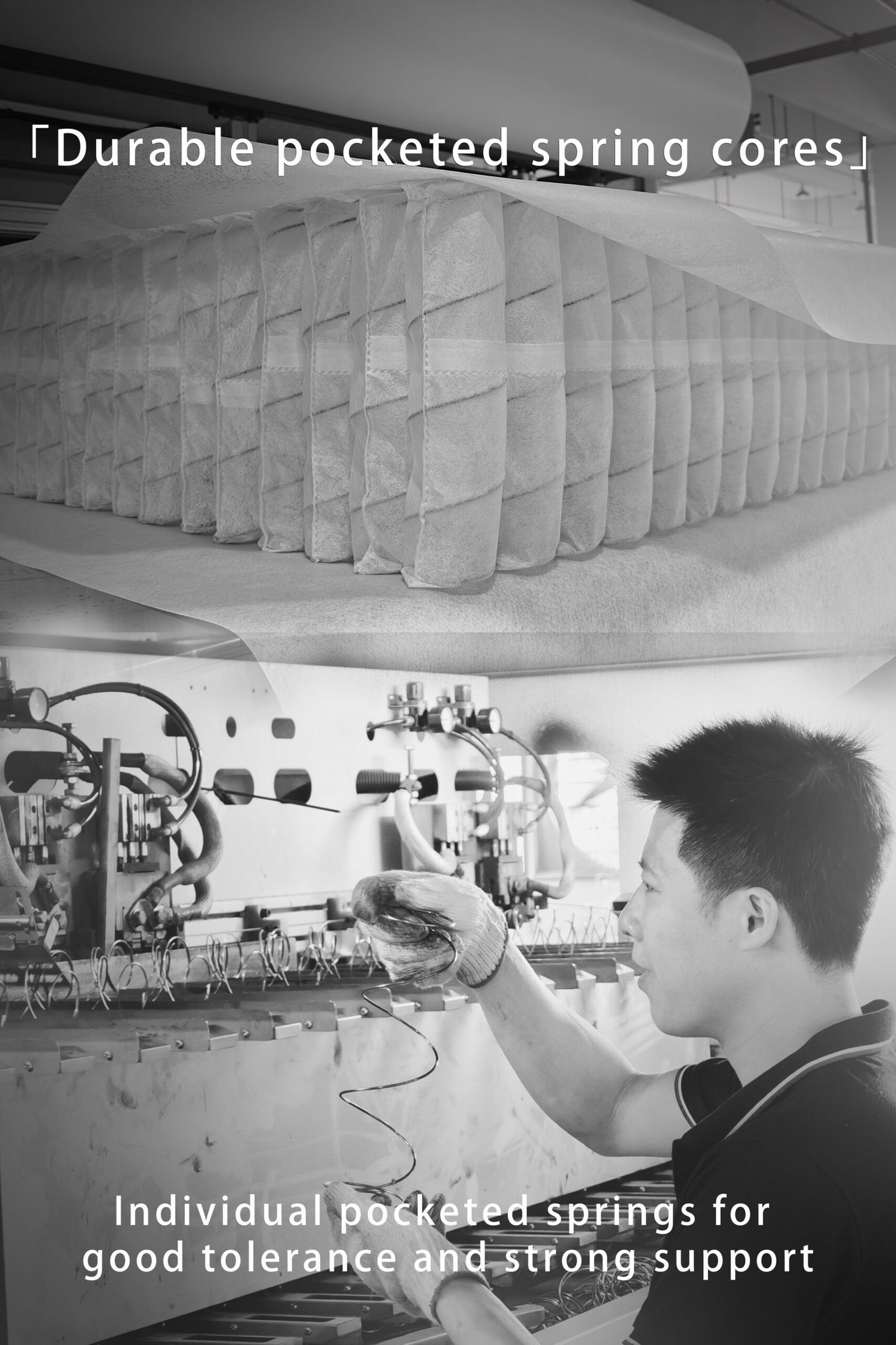

Every sofa starts with materials. If your foam, fabric, or frame is inconsistent, nothing else matters.

Top suppliers conduct rigorous incoming inspections on all foam, fabric, wood, and hardware before production.

Our Material Testing Includes:

| Material | Test Type | Standard |

|---|---|---|

| Foam | Density & rebound rate | ≥30kg/m³, ≥95% shape recovery |

| Fabric | Abrasion & tear test | ≥20,000 Martindale cycles |

| Wood | Moisture & strength | ≤12% moisture, FSC-certified |

| Staples/Glues | Toxicity & hold | RoHS, ISO 10993 pass |

We use calibrated machines for each test and keep batch records for at least 24 months for traceability.

How do suppliers ensure quality during production?

Mistakes during cutting, stitching, or assembly can cause visible flaws or structural weaknesses.

We use in-line inspections at every stage—from frame joining to final packaging.

Production Checkpoints:

- Cutting Stage: Tolerances of ±1mm on panels

- Foam Gluing: Tested for even adhesion and rebound

- Stitching: Thread strength & alignment inspection

- Frame Assembly: Load-bearing stress checks

- Pre-Packaging: 8-point visual and mechanical inspection

Only passed units go to compression. Failed units are flagged, repaired, or rejected based on severity.

What are the compression-specific QC requirements?

Compression is what makes these sofas unique—but also where most damage happens if not handled correctly.

Suppliers must manage pressure, sealing, and packing dimensions carefully to protect product integrity.

Compression Process Standards:

| Step | Requirement |

|---|---|

| Compression Ratio | 3:1 to 5:1 (varies by model) |

| Pressure Control | Max 2.5 PSI for foam |

| Wrapping Film | Triple-layer, anti-puncture, UV proof |

| Box Load Test | ≥300kg vertical stacking resistance |

We test every lot for decompression performance—ensuring 95% shape recovery within 24 hours.

How are finished products tested?

Final product testing ensures that what leaves the factory holds up to real-world use—and customer expectations.

Every batch goes through simulated use testing, decompression evaluation, and durability trials.

Key Tests We Run:

- Drop Test (ISTA 2A): Simulates courier mishandling

- Recovery Test: Measures post-decompression shape and firmness

- Load Test: 150kg static weight for 24 hours

- Fabric Resistance: UV fade and stain repellency

We log all results digitally and link them to the batch number for post-sale tracking and audits.

Who performs these checks—and how are they trained?

Having standards means nothing if your team can’t enforce them.

All QC staff at HEYAN undergo a 2-week onboarding program + monthly skill refreshers.

Training Focus Areas:

- Tool usage (calipers, gauges, rebound testers)

- ISO 9001 documentation protocols

- Common product faults and detection

- Cross-department collaboration (production + QC)

We also reward staff for early detection of quality issues, creating a proactive quality culture.

What tools and software support QC?

From manual calipers to digital dashboards, quality tools matter.

Top suppliers integrate hardware testing tools with digital record-keeping for full traceability.

Essential QC Tools:

| Tool | Function |

|---|---|

| Digital Caliper | Component measurement |

| Rebound Tester | Foam resilience check |

| Moisture Meter | Wood moisture control |

| Pressure Chamber | Compression simulation |

| QC Dashboard | Batch-level defect tracking |

All data is uploaded to our ERP system, linked to barcode labels on each product.

How do suppliers handle feedback and returns?

What happens after the sofa is delivered matters just as much as what happens before.

A closed-loop QC system includes feedback collection, defect analysis, and corrective action tracking.

We collect post-sale feedback through:

- Customer service reports

- Amazon/Shopify reviews

- Distributor return logs

If a defect rate exceeds 2% on any SKU, it triggers a supplier-side RCA (Root Cause Analysis) and corrective action with revised SOPs.

Are QC standards updated regularly?

Market expectations evolve—so should your standards.

At HEYAN, we update our internal QC benchmarks every 6 months based on product upgrades, materials, and shipping methods.

We also benchmark against global standards like:

- ISO 9001 (quality systems)

- EN 12520 (domestic seating durability)

- ASTM D3574 (foam compression)

- REACH & RoHS (chemical safety)

Continuous improvement isn’t optional—it’s survival.

Conclusion

The best compressed sofa suppliers treat quality as a system, not just a checklist.