More packaging? More waste? Not with compressed sofas. This innovation is reshaping the furniture industry's carbon footprint.

Compressed sofa suppliers lead sustainability by reducing emissions, minimizing waste, using eco-friendly materials, and educating consumers on greener living.

In our factory, we don’t just compress sofas—we compress the environmental cost of making and moving them.

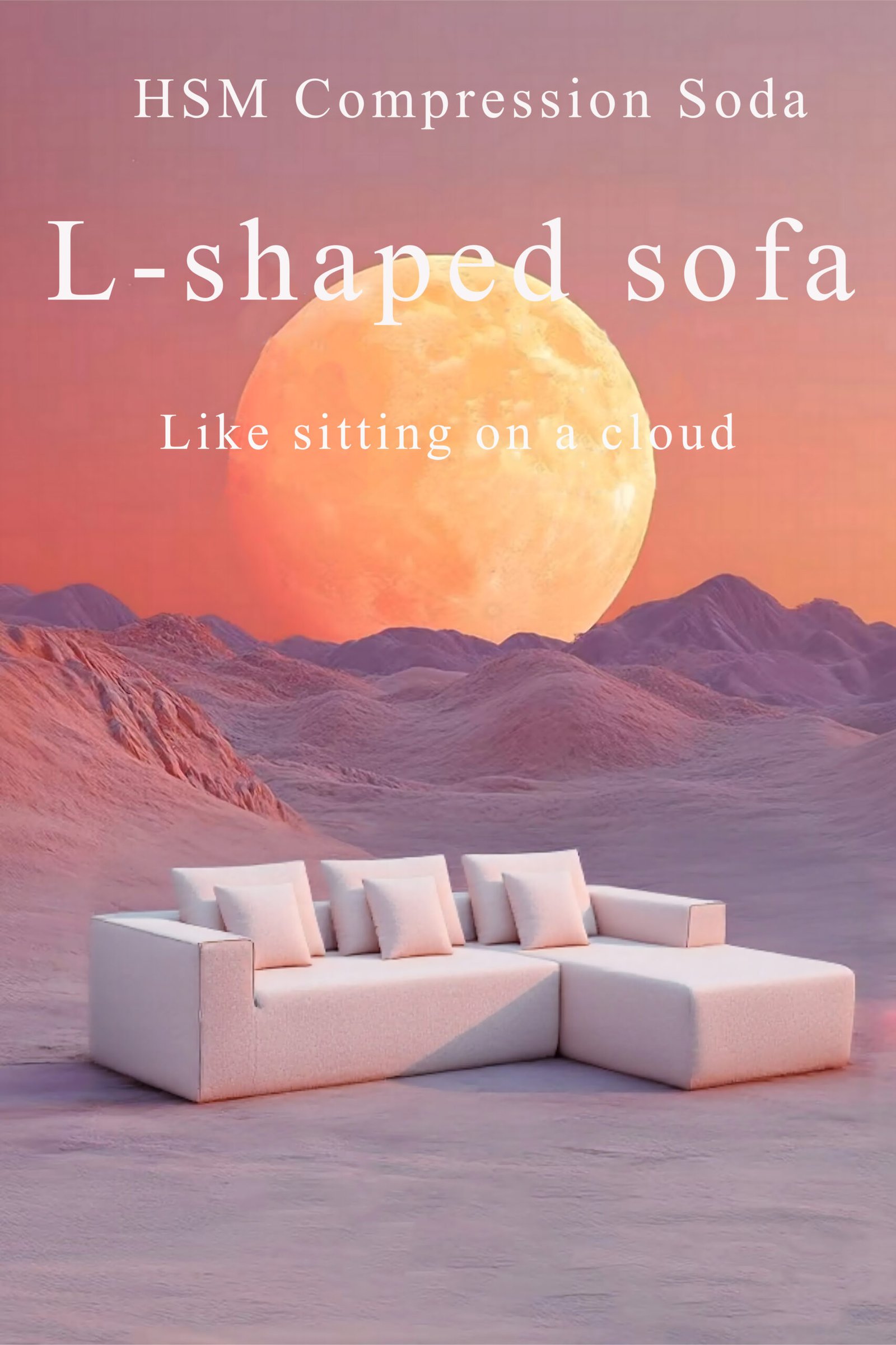

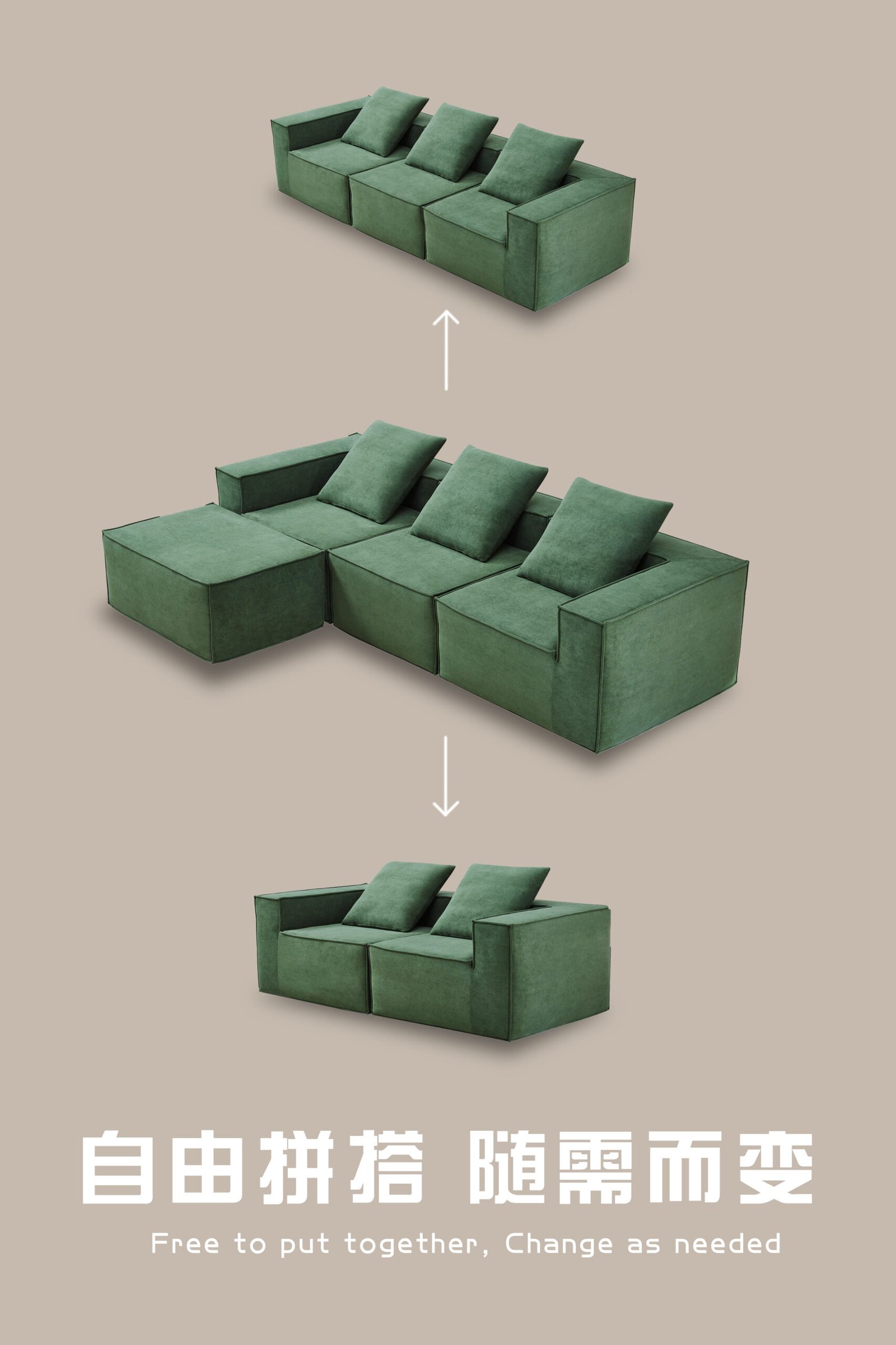

What makes compressed sofas different from traditional furniture?

Traditional sofas are bulky, heavy, and hard to ship sustainably.

Compressed sofas are flat-packed and vacuum-sealed for efficient delivery, cutting down packaging waste and carbon emissions.

They require fewer trucks, fewer raw materials, and less space in warehouses.

Key Differences

| Feature | Traditional Sofa | Compressed Sofa |

|---|---|---|

| Packaging | Large, rigid | Flat-packed, vacuum-sealed |

| Transport Efficiency | Low – bulky and heavy | High – 3x more units per truck |

| Assembly | Pre-assembled | Tool-free DIY setup |

| Shipping Cost | Higher | Lower due to compact packaging |

Why is traditional furniture so unsustainable?

Wood waste, plastic wraps, diesel trucks—these are part of every traditional sofa’s lifecycle.

The old way of making and moving furniture results in high emissions, deforestation, and landfill waste.

- High emissions from inefficient freight

- Excessive raw material use, including non-renewable woods

- Limited recyclability, leading to landfill overflow

This is the gap compressed sofa suppliers are trying to close.

What sustainable materials do compressed sofa suppliers use?

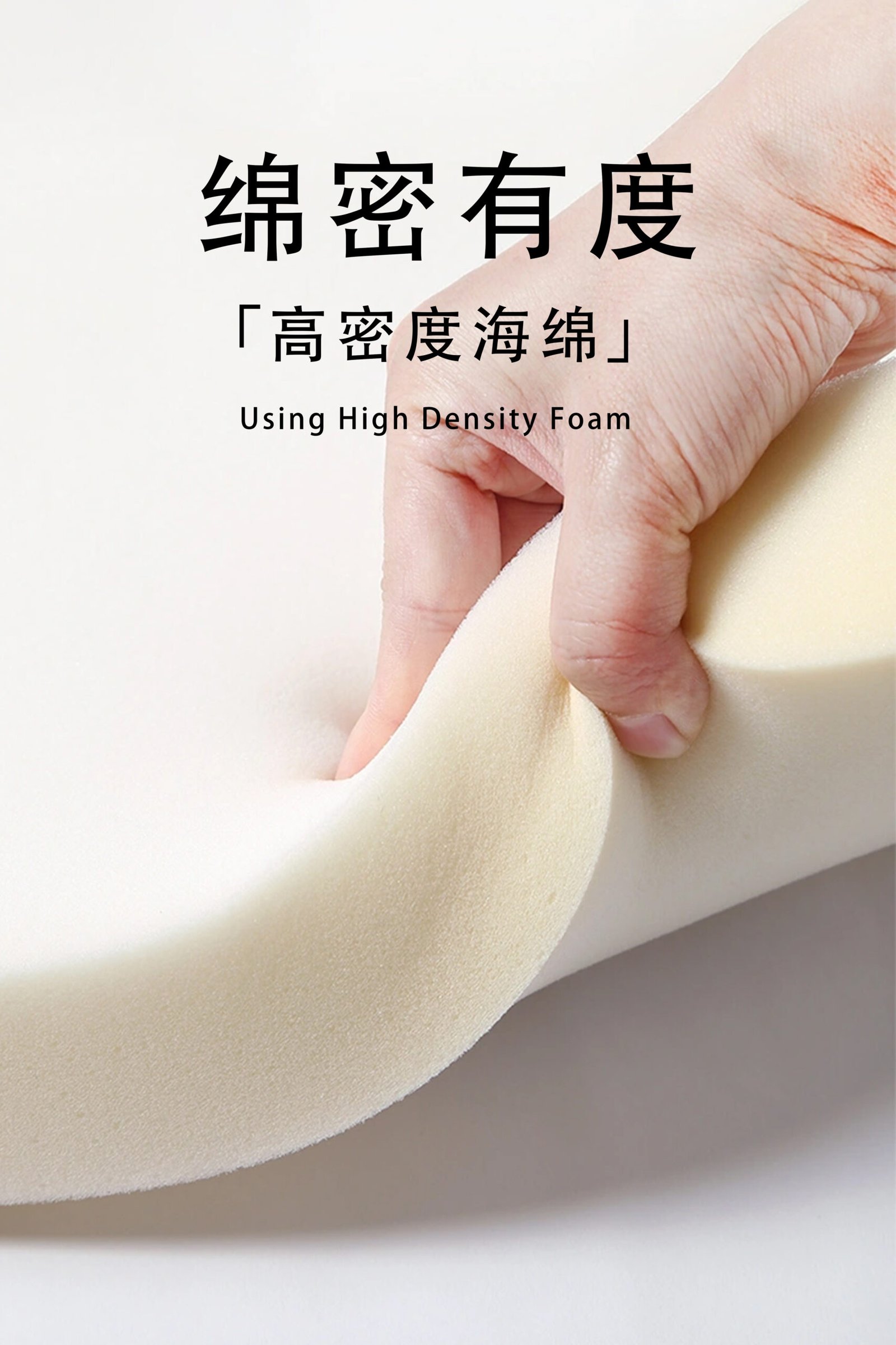

Not all foam is created equal. Not all fabric has to be new.

Suppliers now use recycled PET fabrics, FSC-certified wood, biodegradable packaging, and water-based adhesives.

Common Sustainable Materials

| Material | Description |

|---|---|

| Recycled polyester | Made from old plastic bottles |

| FSC-certified plywood | Wood from responsibly managed forests |

| Biodegradable wrap | Cornstarch-based, breaks down in months |

| Non-toxic glue | Water-based, formaldehyde-free adhesives |

Our most popular fabric now comes from post-consumer plastic—and it’s just as soft.

How do suppliers cut waste in the factory?

Every cut counts.

Factories use automated fabric-cutting machines and CNC wood cutters to minimize offcuts, and they recycle foam trimmings into new seat cores.

- Smart layout algorithms optimize cutting

- Scrap foam is shredded and reused

- Water-saving dye processes for fabric finishing

- Solar-powered workshops in select regions

These efficiencies aren’t just good for the planet—they reduce costs, too.

How does compact packaging help the environment?

One compressed sofa takes up 1/3 the space of a traditional one.

That means three times as many sofas per container, less fuel burned per mile, and fewer delivery trips needed.

- Up to 75% fewer emissions per unit delivered

- Lower shipping costs—passed to consumers

- Less protective plastic needed

At HSM, we fit 60+ sofas in one container. A traditional shipment might fit 20.

Are compressed sofas built to last?

Fast to unpack doesn’t mean fast to break.

Suppliers design for longevity—modular systems, replaceable covers, and upgraded frames for 5+ year durability.

- Removable, washable covers

- Bolt-free joints for easy repairs

- Replaceable seat cores to reduce waste

We offer spare part kits instead of full replacements—less cost, less waste.

How do compressed sofa suppliers support local economies?

Think global, source local.

By using local fabrics, nearby foam plants, and regional factories, suppliers cut shipping emissions and support local jobs.

- Local sourcing = fewer transport miles

- More skilled jobs in regional hubs

- Faster production turnaround

Our newest model uses 80% Chinese-made components—all from within 200km of our factory.

How do suppliers educate consumers?

It’s not sustainable if the customer doesn’t know how to recycle it.

Suppliers provide care guides, recycling instructions, and certifications to help customers make greener decisions.

- QR codes linking to disposal instructions

- Labels showing CO₂ savings vs. traditional models

- Email newsletters on sofa lifecycle care

We even added an assembly video that reminds customers where to recycle the box.

What certifications show a sofa is sustainable?

Sustainability isn’t a claim—it’s a certificate.

Compressed sofa suppliers follow strict standards: FSC, OEKO-TEX, CertiPUR-US, and ISO 14001.

Common Certifications

| Certification | What It Covers |

|---|---|

| FSC | Responsible wood sourcing |

| CertiPUR-US | Low-emission foam |

| OEKO-TEX Standard 100 | Safe textiles free from harmful substances |

| ISO 14001 | Environmental management systems |

We ensure every foam block is CertiPUR-US certified—no VOCs, no guilt.

What’s next for sustainability in sofas?

The sofa of the future will be circular, digital, and carbon-aware.

Expect more recycled content, digital twins for reuse tracking, and disassembly-focused design.

- Sofa take-back programs for upcycling

- Bio-resins for frame bonding

- QR-code-based repair parts ordering

- Modular sofa credits in carbon offset plans

The next wave is not just less waste—but zero waste.

Conclusion

Compressed sofa suppliers support sustainability at every stage—from recycled fabrics to flat-pack shipping to modular durability. They're not just making smaller sofas. They're making a smaller impact.