Product returns are stressful—for customers and sellers. Mishandling them leads to bad reviews and lost trust.

Compressed sofa suppliers manage returns through clear policies, structured logistics, careful inspections, and responsive customer support.

Done right, a return isn’t a loss—it’s a chance to improve the customer experience and protect your brand.

What kind of return policies do compressed sofa suppliers offer?

If your policy is vague or hard to find, you’ll lose customer confidence—and possibly sales.

Compressed sofa suppliers usually offer 30–90 day return windows, with conditions for repackaging, inspection, and partial refunds depending on product condition.

Common Return Policy Elements

| Policy Component | Typical Practice |

|---|---|

| Return Window | 30–90 days after delivery |

| Condition Requirements | No damage, minimal use, original packaging |

| Restocking Fee | 10–30% if item is opened or lightly used |

| Return Shipping | Often covered if item is defective |

| Proof Required | Photos of defect or delivery damage |

At HSM, we send a PDF return guide with every order—this transparency cuts down on disputes and helps buyers plan ahead.

How do customers initiate a return?

A good return process starts with clear instructions. Confused customers = frustrated reviews.

Buyers usually start a return via email, phone, or an online portal by providing their order number, problem description, and photos.

Step-by-Step Return Request

- Contact support via designated channel

- Submit order ID, delivery date, and photos if required

- Explain issue: defect, mismatch, damage, or dissatisfaction

- Wait for response—usually within 24–48 hours

We always recommend offering a return initiation form with dropdown reasons (e.g. wrong size, damaged on arrival, doesn’t match listing). This makes backend sorting easier.

How do suppliers evaluate and approve return requests?

Not all return requests are valid. But rejecting genuine ones damages trust. Balance is key.

Suppliers assess return claims based on evidence of defects, damages, or mismatch against order specs.

Return Validity Checklist

| Return Reason | What We Check |

|---|---|

| Manufacturing Defect | Close-up photos, production batch data |

| Shipping Damage | Unboxing photos, packaging condition |

| Wrong Product | SKU match, color or size discrepancy |

| Customer Dissatisfaction | Use pattern, evidence of excessive wear |

If a sofa has been used for 6 weeks and smells of pets, we may still accept a return—but with partial refund only.

What happens after a return is approved?

Approval is just the start—getting the sofa back safely is another challenge.

Once approved, suppliers issue prepaid return labels, packaging instructions, and pickup coordination if needed.

What We Provide to the Customer

- Return label (email or print-at-home)

- Compression guide to repackage the sofa

- Pickup schedule (for larger units or bulk orders)

- Support contact in case of shipping issues

Because compressed sofas are bulky, we also provide instructions on how to fold or re-bag the product to protect it during return transit.

How do suppliers manage reverse logistics?

Returned sofas must travel safely—again. That takes planning and coordination.

Suppliers use reverse logistics tools and shipping partners to track and manage the return trip, from customer to warehouse.

Reverse Logistics Key Actions

- Assign tracking number for return

- Monitor return pickup and transit

- Notify warehouse of incoming return

- Route item to inspection area on arrival

Some clients use regional return hubs to reduce international return costs. At HSM, we offer DDP returns to simplify the customer experience in Canada and Europe.

How are returned sofas inspected and processed?

Every returned sofa needs careful inspection before restocking or refunding.

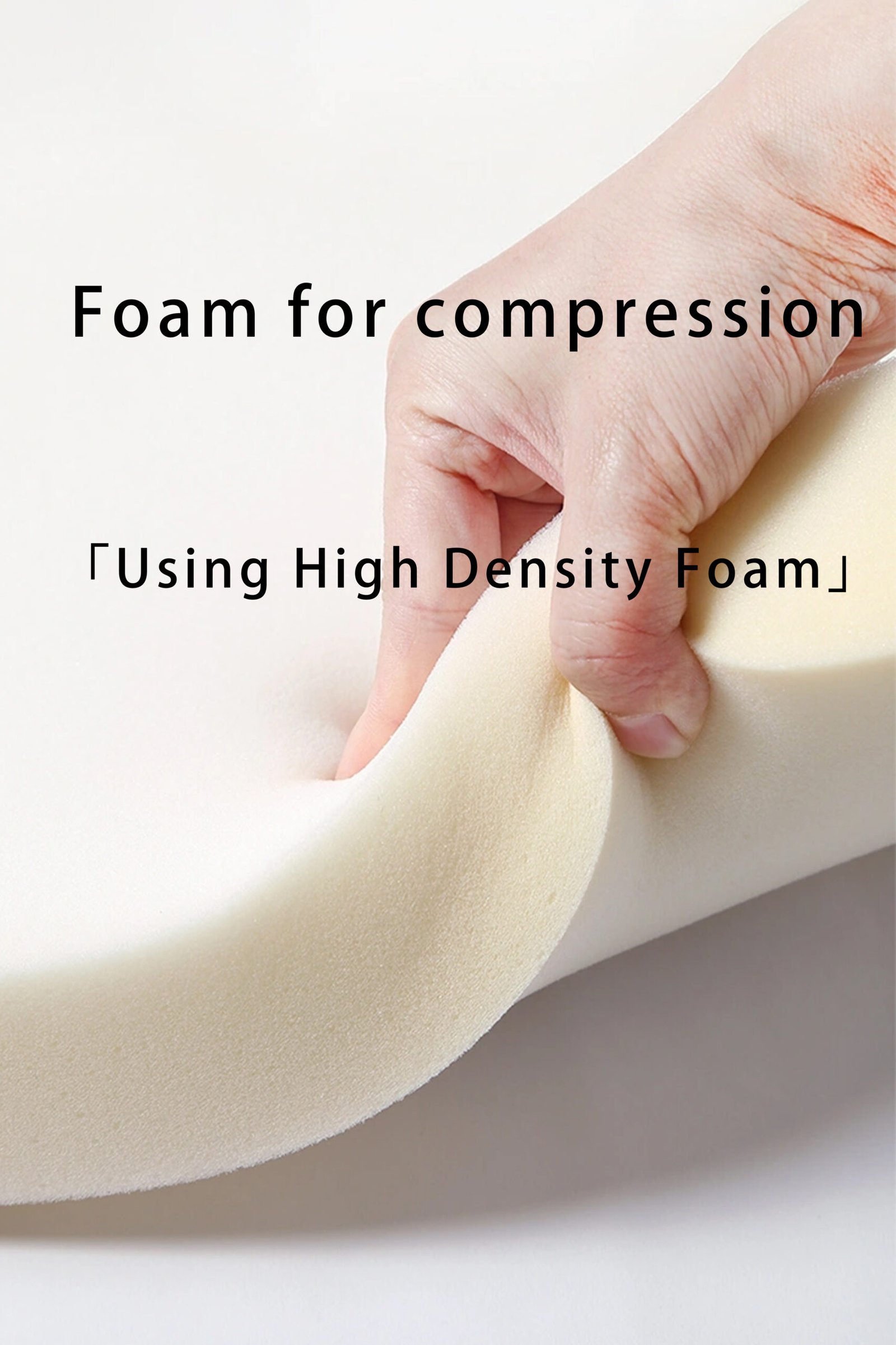

Returned sofas go through a structured inspection—checking frame, fabric, odor, compression integrity, and overall resale potential.

What Our QC Team Checks

| Checkpoint | Details |

|---|---|

| Frame Integrity | No cracks, looseness, or warping |

| Fabric Condition | No stains, pet hair, or tears |

| Foam Compression | Retains original bounce and volume |

| Odor Test | No smoke or mildew smell |

| Packaging Reusability | Is the box or bag intact? |

Items that pass all checks are re-sanitized, vacuum-sealed again, and added to outlet inventory. Damaged ones are either refurbished or scrapped.

How are refunds or exchanges processed?

Refund timing and clarity are key—uncertainty damages reputation.

Suppliers process full or partial refunds within 3–7 business days after product inspection, or offer exchanges based on availability.

Refund Options

| Situation | Refund Type |

|---|---|

| Full product defect | 100% refund including shipping |

| Minor defect, customer keeps | 30–50% partial refund |

| Opened but unused | Refund minus restocking fee |

| Exchange requested | New item shipped with no extra fee |

Clear communication during this stage builds trust. We always send refund confirmation plus tracking for any replacement sent.

How do suppliers use return data to improve?

Every return tells a story—if you’re listening.

Suppliers track return reasons, product types, shipping partners, and buyer segments to reduce future returns.

Metrics We Analyze

- Top 5 return reasons this quarter

- Most returned SKUs by region

- % of issues from shipping vs. production

- Impact of packaging changes on return rate

- Customer satisfaction scores post-return

This helps us refine sofa designs, update packing methods, and even retrain logistics partners if needed.

Conclusion

Compressed sofa suppliers handle returns with a system that balances product protection, customer care, and data-driven improvement—turning a challenge into a brand-building opportunity.