One bad sofa can destroy your brand—but consistency turns buyers into loyal customers.

Compressed sofa suppliers ensure consistent quality by managing materials, standardizing production, using automated testing, and listening closely to customer feedback.

For compressed sofas, maintaining uniform quality is harder than it looks. These products are folded, shipped, expanded—then judged in seconds.

How do raw materials affect sofa quality?

A sofa’s quality starts before production—at the material source.

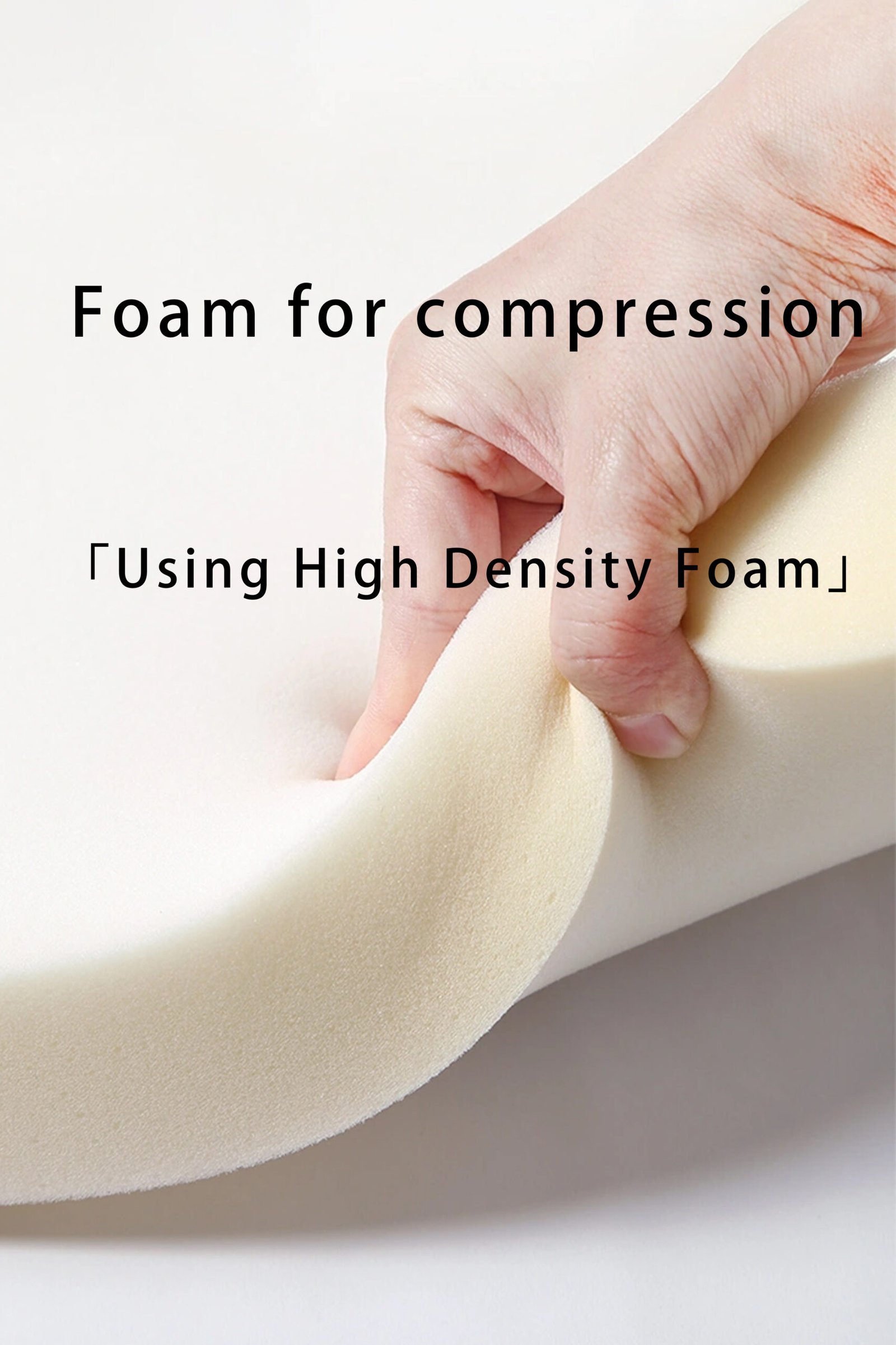

We ensure consistent quality by sourcing only from certified suppliers and setting strict standards for foam, fabric, and frames.

At HSM, every material is evaluated for:

- Durability: Can it withstand compression and still hold shape?

- Safety: Does it meet international standards like CertiPUR-US or OEKO-TEX?

- Performance: Will it pass our repeated fold-unfold tests?

Our top material criteria:

| Material | Quality Checkpoints |

|---|---|

| Foam | Density (≥35kg/m³), resilience |

| Wood/Plywood | FSC-certified, moisture below 12% |

| Fabric | Martindale ≥ 20,000 rubs, colorfast |

| Metal Frames | Rust-resistance, torque-tested joints |

Raw material inspection is our first quality checkpoint. Any lot that fails is sent back.

What supplier vetting process guarantees material quality?

You can’t build quality from weak links.

We run detailed audits on all raw material suppliers—checking their quality control systems, past defect rates, and industry certifications.

Before any supplier joins our chain, they pass:

- Document review: ISO, REACH, GRS, etc.

- Factory audit: Safety, hygiene, machinery quality

- Sample testing: We run performance checks on actual product

Only Grade A vendors enter long-term contracts. We also schedule re-evaluations every 12 months.

This is how we keep the same cushion feel—batch after batch, year after year.

How does technology improve production consistency?

Humans have skill. Machines offer precision.

We integrate automated cutting, stitching, and compression to remove human error and ensure each sofa is built the same way.

Technology used:

| Stage | Tech Involved | Benefit |

|---|---|---|

| Cutting Fabric | CNC auto-cutting | ±0.5mm precision |

| Foam Processing | Horizontal + vertical slicers | Clean edges, no tearing |

| Frame Assembly | Jig-based drill systems | Exact joint spacing |

| Compression & Sealing | Programmable vacuum compressors | Repeatable compression ratio |

This reduces rework, increases batch uniformity, and ensures scale without compromise.

Plus, our machines are IoT-enabled—they alert us when something goes off spec.

How do we handle quality control on the floor?

Spot-checking isn’t enough. We inspect at every step.

Our 5-stage quality control system catches issues before they leave the floor.

HSM Quality Flow:

- Raw Material Check: Moisture, density, load bearing

- Mid-Assembly Inspection: Joint fit, staple alignment

- Upholstery Audit: Seam tightness, stitch count

- Final Product Review: Function, size, aesthetics

- Compression Test: Expansion shape, box integrity

We use barcode scanning to link each sofa’s components to its inspection record. This way, if one part fails—we trace it instantly.

We also maintain AQL 1.5 level inspection for international clients who need strict conformance.

How do employees help maintain consistent quality?

Machines do the repeat work. People make the smart calls.

We train every worker to identify flaws and fix them—not ignore them.

Every new team member goes through a 2-week skill training focused on:

- Identifying material defects

- Operating factory equipment

- Reporting process deviations

- Following safety and hygiene rules

We run monthly workshops on new tools and common failure patterns.

Consistency comes from a team that knows why details matter.

What role does customer feedback play?

You don’t need mystery shoppers when your real buyers leave clues.

We use customer feedback to update designs, packaging, and materials.

How we collect feedback:

- QR-code surveys in every box

- Shopify and Amazon review monitoring

- After-sale emails and B2B interviews

When complaints spike (e.g., “sofa back too low”), we flag the model. Our R&D team runs a redesign sprint within 30 days.

Example:

A major client in Canada flagged repeated zippers breaking during decompression. We switched to YKK zippers factory-wide in response—and complaints dropped to zero.

How do we maintain long-term consistency?

Great quality once is luck. Great quality always is a system.

We build consistency into our process through audits, testing, and data tracking.

Our long-term quality systems include:

- Monthly defect analysis reports

- Quarterly supplier scorecards

- Annual full-process audits

- Customer satisfaction tracking (CSAT score > 92%)

We also review returns weekly to update SOPs and prevent future issues.

Conclusion

Consistent quality in compressed sofas comes from strict sourcing, smart technology, trained staff, and fast feedback loops. At HSM, we don't leave it to chance—we build systems that make every sofa reliable, comfortable, and ready to impress.