Trends shift fast, and what worked last year might lose customers today.

Compressed sofa suppliers adapt by upgrading designs, improving processes, embracing eco-materials, and refining digital marketing to stay competitive in a changing market.

The furniture industry is evolving. Urbanization, sustainability, and e-commerce are rewriting the rules—especially for compressed sofa businesses.

What’s driving changes in market demand?

City living, work-from-home setups, and online shopping have changed how people buy furniture.

Customers now want furniture that saves space, is easy to move, looks modern, and supports sustainable values.

Compressed sofas tick many of these boxes—but suppliers can’t rely on old designs or traditional sales models anymore.

Let’s look at how successful suppliers like us are adapting in real-time.

How do we innovate compressed sofa products?

Every few months, customer expectations shift. A sofa that simply “compresses well” is no longer enough.

Product innovation is key—adding smarter features, using better materials, and making designs more modular and stylish.

We’ve made R&D a priority. That means:

- Using lightweight metal frames to reduce weight without losing durability

- Offering modular add-ons like attachable tables or under-seat storage

- Launching tool-free assembly systems for e-commerce buyers

Here’s how we break it down:

| Innovation Area | What We Did | Result |

|---|---|---|

| Materials | Replaced pine with engineered wood + steel | Increased strength + lower cost |

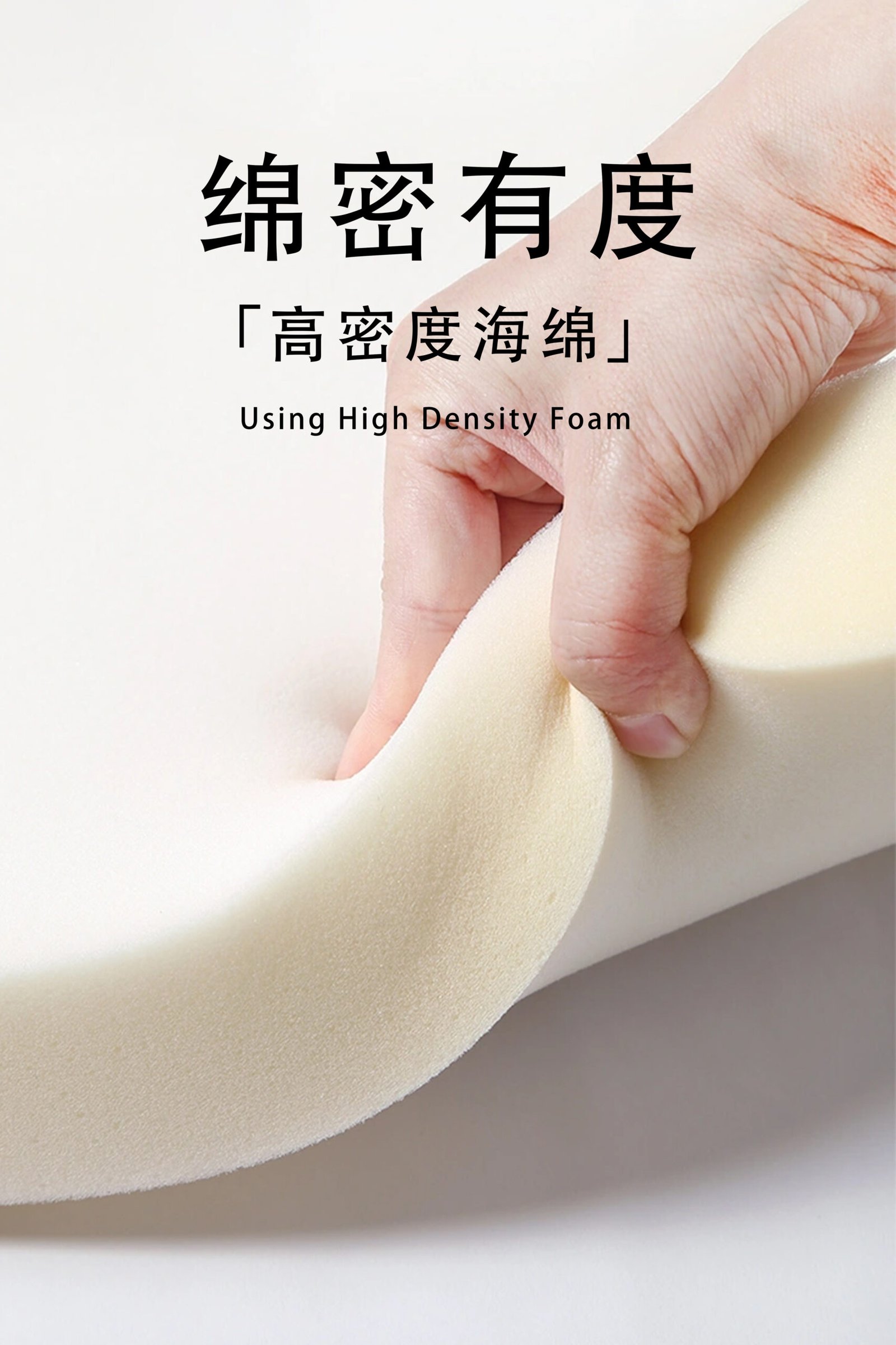

| Foam Tech | Switched to CertiPUR-US foam | Better comfort, healthier foam |

| Aesthetics | Hired freelance designers from Milan | Modernized our color palettes |

Customers today want versatility. We once had a buyer request a sofa that doubles as a workspace. That feedback sparked a whole new laptop-table armrest product line.

Innovation doesn’t always mean big changes—it means useful ones.

How are production processes getting smarter?

Demand is up. But quality and speed need to scale together.

Suppliers now adopt automation, lean workflows, and modular production to cut waste, boost consistency, and lower cost.

At HSM, we run 10+ automated production lines. That’s how we keep up with:

- Global demand spikes during sales seasons

- E-commerce delivery timelines

- Quality control across batches

What’s changed in our factory?

- Added laser cutting systems for foam and fabric

- Introduced real-time QA dashboards

- Trained our staff to run smart sewing machines

These upgrades didn’t just improve speed—they dropped our defect rate by 36%.

Also, compressed sofa manufacturing means every millimeter matters. Automation reduces human error and keeps our tolerances tight.

How is sustainability changing the game?

Customers and retailers are asking tougher questions: “Where’s your wood from?” “Is your foam safe?” “Can I recycle your packaging?”

Suppliers are shifting to eco-friendly materials and cleaner operations to meet growing demand for green products.

Here’s what we’re doing:

- Using FSC-certified wood for all frames

- Switching to recycled polyester fabrics

- Replacing Styrofoam packaging with corrugated honeycomb cardboard

This isn’t just for the environment. One European buyer only signs with ISO 14001-certified partners.

And yes—it adds costs. But eco-investments pay off through:

- Premium product positioning

- Lower rejection rates in regulated markets

- Stronger brand reputation

Quick Tip:

If you're not promoting your sustainability, you're missing a key selling point—especially on Amazon, TikTok, and Shopify.

How does customer feedback shape product strategy?

Negative reviews hurt. But they teach.

Smart suppliers collect feedback, fix issues fast, and adjust designs based on real-world use.

We’ve set up a system where every return is logged and reviewed weekly. Patterns in complaints often point to simple fixes:

- Foam too soft? → Upgrade density from 28kg/m³ to 35kg/m³

- Screws missing? → Pre-pack with barcode checklist

- Instructions unclear? → Add QR code with video guide

We also follow up with top buyers through email surveys. Their feedback helps us plan new models.

Customer service isn't just support—it's R&D.

How are marketing strategies evolving?

Old-school catalogs are gone. Today’s buyer checks Instagram before checking out.

Marketing now means positioning your brand on multiple platforms with strong visuals, good storytelling, and clear benefits.

Here’s what works:

- Short videos showing 10-minute assembly

- Before-after photos for small apartments

- “Fits in your car trunk” demo reels

We split-test ads on TikTok and Meta. For one campaign, just changing the line from “space-saving sofa” to “foldable sofa bed under 10 minutes” increased click-through rates by 47%.

Clear value + clear visuals = conversions.

How do we expand to international markets?

Global markets offer huge opportunity—but each one is different.

Suppliers must research local preferences, adjust packaging, and meet specific certification standards.

Here’s how we break it down:

| Market | What They Care About | Our Tactic |

|---|---|---|

| U.S. | Fast delivery + comfort | Partnered with Amazon FBA warehouses |

| Germany | Eco-certifications + modularity | Highlighted FSC + ISO 14001 in ads |

| Middle East | Larger family units | Offered extended 4-seat options |

| Japan | Space-saving + light colors | Custom fabric collections |

We also use collapsible packaging tailored to container optimization for different routes—helping reduce freight costs by 15–20%.

Expanding globally isn’t about shipping more. It’s about selling smarter per region.

Conclusion

Compressed sofa suppliers adapt by listening to customer needs, improving product design, going green, upgrading tech, and fine-tuning market approaches. That’s how we stay ahead—one adjustment at a time.