Springs that break, sag, or fail under stress can ruin a product’s performance—or even cause serious damage. But heat treatment innovation is changing that.

Advanced heat treatment strengthens spring steel at the micro level—boosting fatigue life, resilience, and load-bearing power.

Whether in sofas, cars, or aerospace, better springs start with smarter metallurgy.

What exactly is advanced heat treatment?

If a spring is the heart of a system, then heat treatment is what gives it life.

Heat treatment is the precise heating and cooling of metal to change its internal structure—and improve its strength, toughness, and elasticity.

The most common processes include:

| Process | Purpose |

|---|---|

| Annealing | Softens metal and removes internal stress |

| Quenching | Rapid cooling to harden steel |

| Tempering | Reheating to reduce brittleness after quenching |

| Cryogenic | Ultra-low temp treatment to improve grain uniformity |

| Induction | Localized heating with electromagnetic coils |

| Laser Hardening | Pinpoint heat zones to strengthen specific areas |

These aren’t just old-school forge techniques. Today, they’re powered by CNC, AI, and laser control.

Why does heat treatment matter for spring performance?

Springs work under pressure—literally.

They bend, stretch, or twist over thousands of cycles without breaking. Heat treatment controls the spring’s internal structure so it can handle that stress.

Without it, even a strong-looking spring can:

- Sag over time

- Snap under shock

- Corrode or crack under fatigue

With proper treatment, the same spring can deliver years of reliable use.

What properties does heat treatment improve?

Here’s how performance improves when the steel is treated right:

| Property Improved | How It Helps Spring Performance |

|---|---|

| Fatigue resistance | Withstands millions of stress cycles without cracking |

| Elastic recovery | Returns to shape even after deep deflection |

| Load-bearing capacity | Carries more weight without permanent deformation |

| Hardness | Resists wear and surface indentation |

| Corrosion resistance | Withstands moisture, chemicals, and oxidation |

Microstructure Matters

Most of these improvements come from what happens inside the metal.

During heat treatment, the crystalline structure of steel transforms. For example:

- Austenite becomes martensite after quenching—hard, but brittle

- Tempering modifies martensite into a tougher, springy form

- Cryogenic treatments refine the grain for added fatigue life

This is material science with measurable impact.

How does this apply to different types of springs?

Different spring designs have different jobs—and need specific treatments.

| Spring Type | Treatment Focus |

|---|---|

| Compression | High hardness + fatigue resistance |

| Tension | Good ductility + tensile strength |

| Torsion | Balance between toughness + flexibility |

| Flat/Leaf | Surface hardness to resist sliding wear |

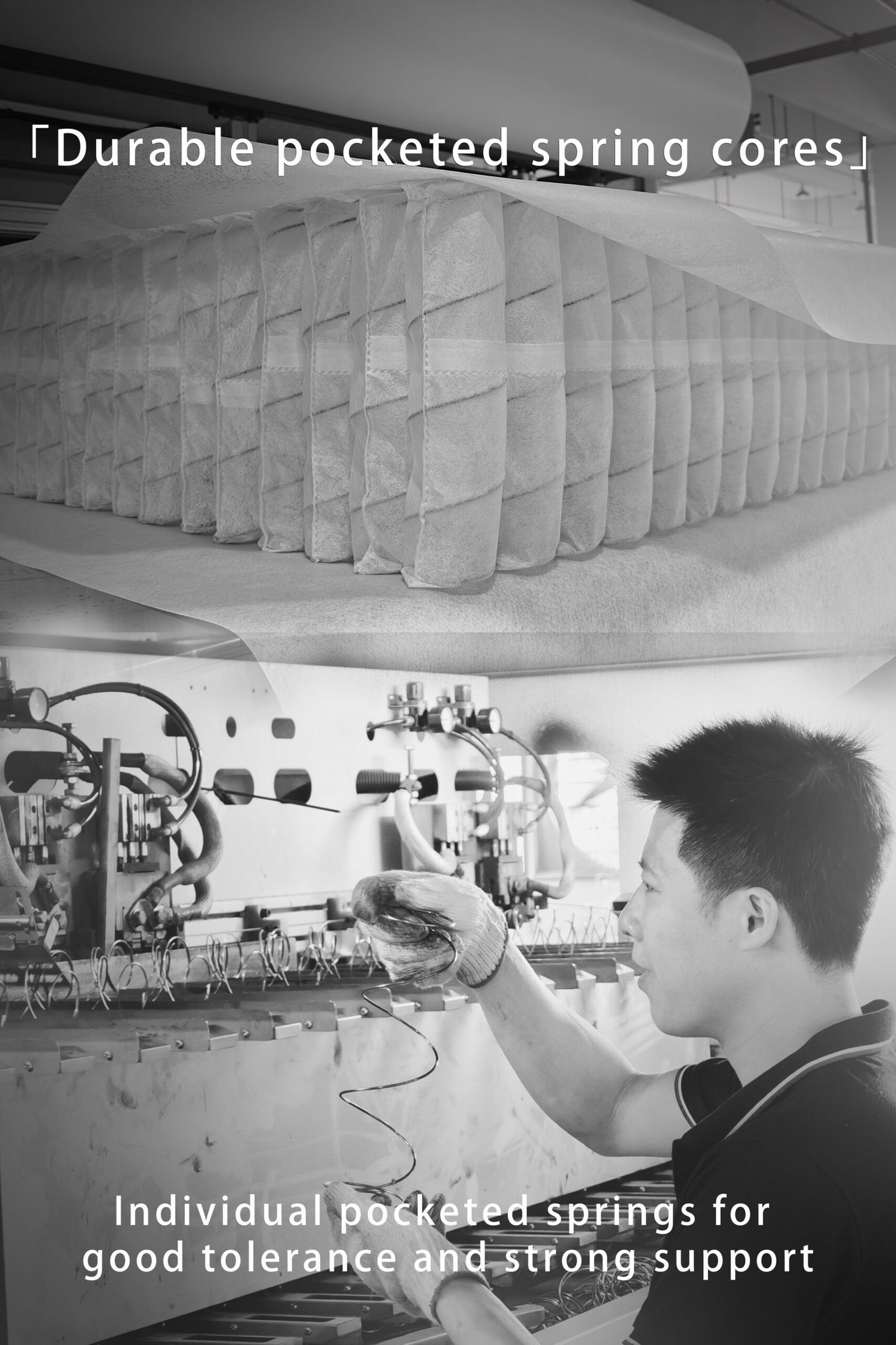

For example, a sofa’s compression spring must compress thousands of times without sagging—requiring precise quenching and tempering.

What advanced methods are leading the industry now?

Manufacturers are replacing generic heating with pinpoint precision.

Induction Heat Treatment

- Heats only specific zones

- Very fast cycle times

- Great for large-scale production

- Perfect for torsion or coil ends

Cryogenic Treatment

- Takes steel to -196°C

- Transforms retained austenite to martensite

- Reduces microcracks

- Boosts fatigue life significantly

Laser Hardening

- Focused beam targets high-wear areas

- No distortion of the entire part

- Ideal for selective surface strengthening

- Used in automotive and aerospace springs

These innovations reduce energy use, improve uniformity, and make springs perform longer under real-world loads.

What’s the impact on sofa springs?

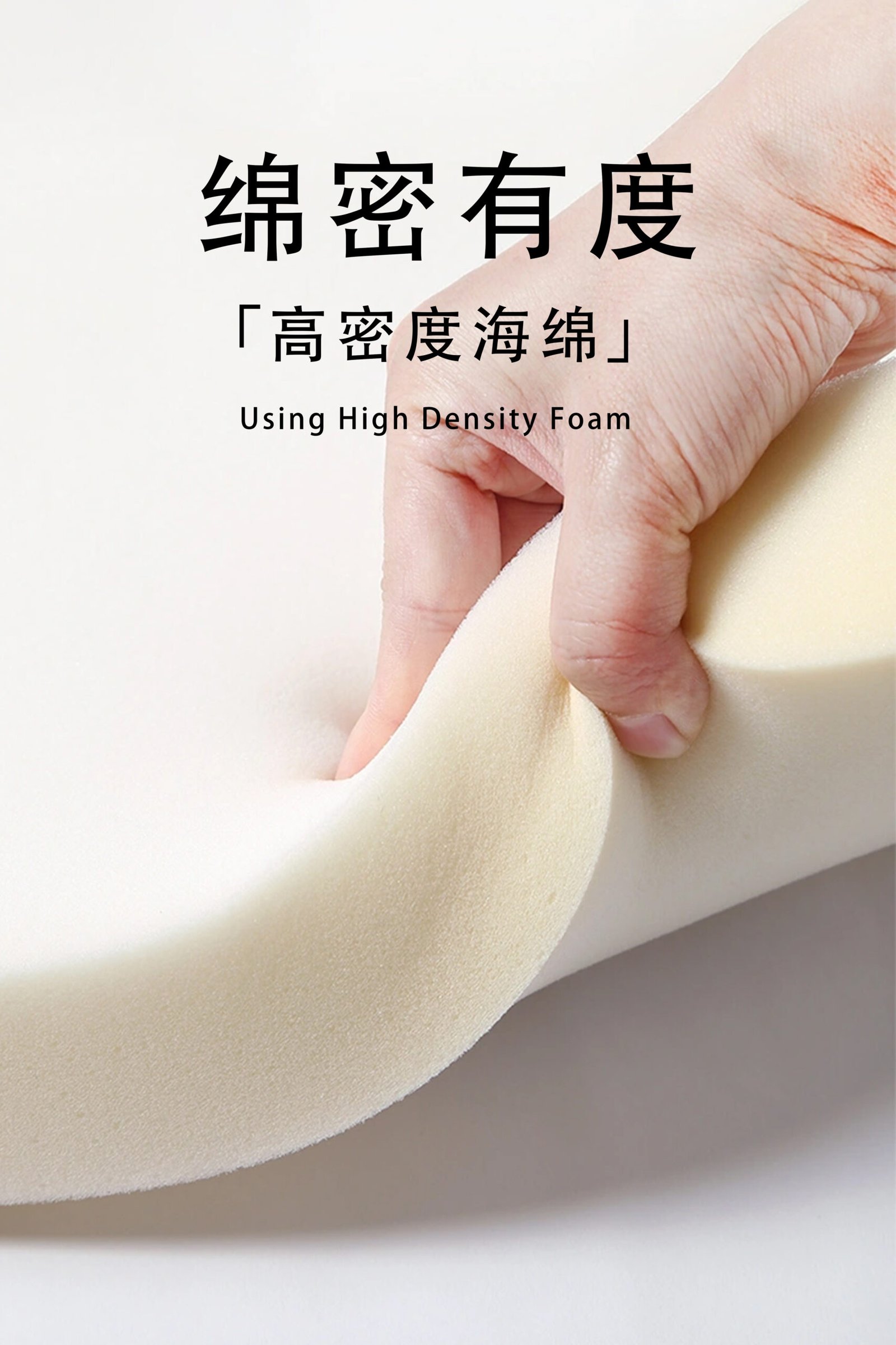

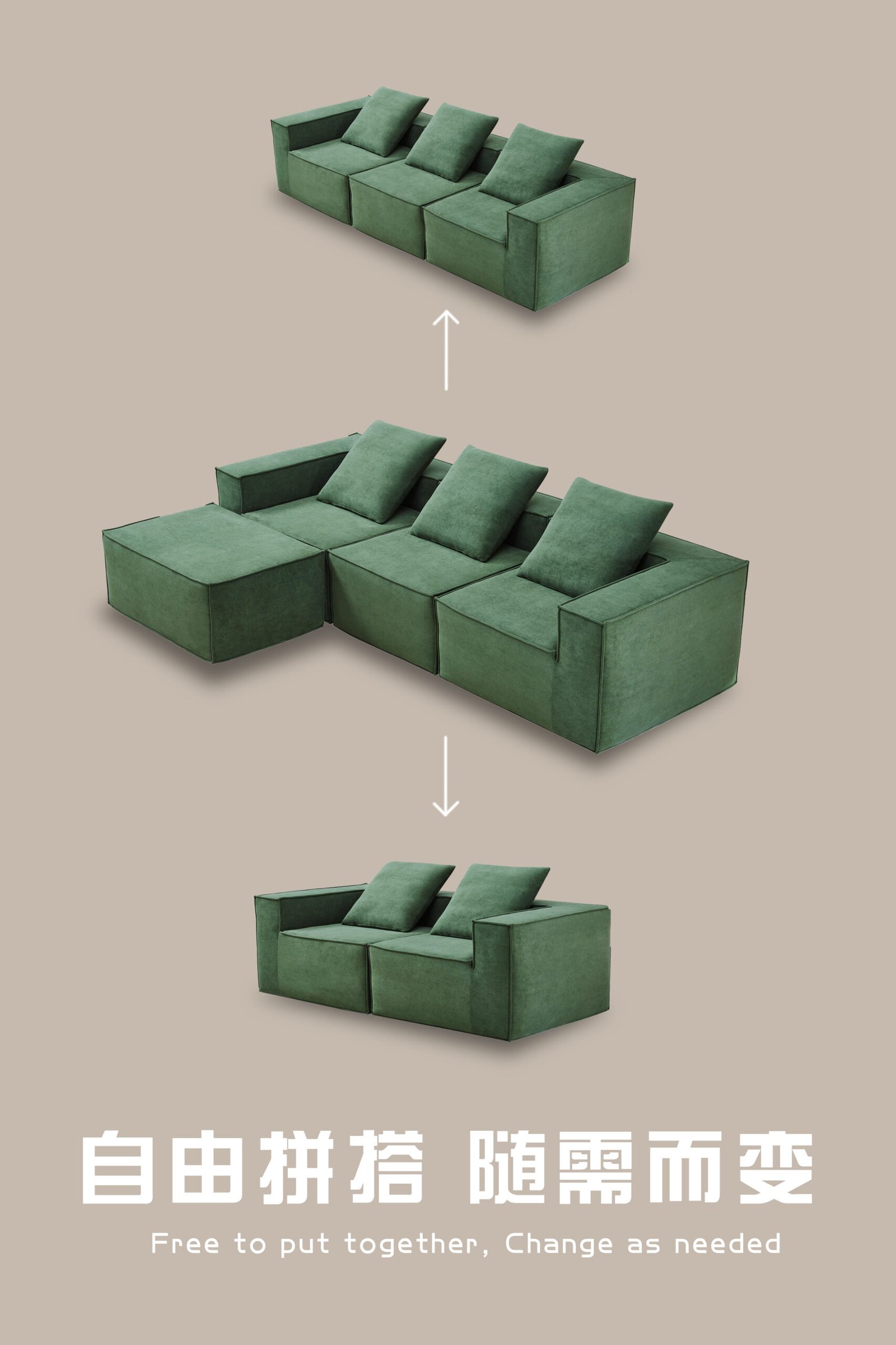

In the compressible sofa industry, comfort and lifespan depend heavily on spring quality.

By using advanced heat-treated springs, compressed sofas gain:

- Better resistance to deformation over time

- Consistent support even after long shipping or compression

- Longer product life under daily home use

- Fewer returns and complaints from sagging cushions

At HSM, for example, we integrate automated tempering and quenching lines to ensure every spring meets optimal performance before compression packaging.

How do manufacturers ensure quality after heat treatment?

Post-treatment testing is critical.

Common methods include:

- Hardness testing (Rockwell or Vickers)

- Fatigue testing (millions of compression cycles)

- Tensile testing (to break point)

- Microstructure inspection under electron microscope

This data ensures each batch meets safety, consistency, and performance specs.

What's next for spring performance?

We’re entering an age of smart metallurgy.

- AI-controlled heat treatment lines adapt to wire type and size in real time

- New alloys optimized for ultra-lightweight but strong springs

- In-line laser tempering during coil winding

- Recyclable, eco-treated springs for sustainable sofas

These technologies will produce smarter, longer-lasting springs—at scale.

Conclusion

Advanced heat treatment isn’t just a backend process. It’s the hidden power behind every high-performance spring.

From automotive to compressed sofas, the durability, comfort, and reliability you feel all start with metal treated right—down to the molecule.