In the modern furniture industry, compressed sofas — compactly packaged, vacuum-sealed sofas that expand to full size after unpacking — have become a revolutionary concept. Their portability, space-saving features, and reduced shipping costs have transformed how consumers purchase and experience sofas. Behind this innovation is the sophisticated construction process employed by a skilled compressed sofa factory such as Modular-Sofas.com, which combines advanced materials, precise engineering, and quality craftsmanship.

This comprehensive guide will take you through every aspect of compressed sofa construction, providing an in-depth explanation of the materials, technology, production steps, and quality control measures involved. The goal is to empower readers with full understanding about how these highly engineered sofas are created to meet modern demands for comfort, style, and convenience.

The Essence of Compressed Sofa Construction

At the heart of every compressed sofa lies a balance between modularity, durability, and compressibility. Unlike traditional bulky sofas, they are crafted for compact packaging without compromising comfort or longevity. This requires special attention to:

- Selecting compressible yet supportive foam fillings

- Designing flexible, foldable frames

- Using stretchable, durable fabrics

- Employing specialized vacuum compression and packaging techniques

Such construction enables sofas to be compressed by up to 90% in volume for shipment, then effortlessly expand back to their original shape and size upon unpacking.

Key Components of a Compressed Sofa

Understanding construction requires recognizing the main components of a compressed sofa:

- Frame: The structural skeleton, providing stability and shape. Usually made from lightweight metals, engineered wood, or composites designed to fold or break down.

- Filling: Foam or other cushioning materials engineered for resilience and elasticity, allowing compression without lasting deformation.

- Fabric Cover: Durable, breathable, and stretchable fabric that wraps the cushioning and frame, designed to endure folding and vacuum sealing.

- Compression Packaging: Vacuum-sealed plastic bags and protective cartons that lock the sofa in a compressed form for transport and storage.

Step-by-Step Guide to Compressed Sofa Construction

The entire manufacturing process of compressed sofas can be divided into distinct, interconnected stages as outlined below.

| Production Stage | Description | Purpose / Key Focus |

|---|---|---|

| Material Preparation | Selection and quality control of frame materials, foam fillings, and upholstery fabrics | Ensures strength, comfort, compressibility, and durability |

| Frame Fabrication | Cutting, welding/assembling foldable sofa frames and surface finishing | Provides rigid yet flexible structure suitable for compression |

| Foam Processing | Cutting, shaping, and sometimes pre-compressing foam pieces | Guarantees uniform comfort and resilience to repeated compression |

| Fabric Cutting & Sewing | Precision cutting of fabric panels and sewing to make stretchable sofa covers | Produces protective, flexible covers tailored to sofa design |

| Assembly | Inserting foam fillings into covers and attaching covers firmly onto the frame | Creates the finished sofa ready for compression |

| Compression Treatment | Vacuum compressing the assembled sofa using specialized equipment while controlling pressure | Reduces shipping volume, maintains product integrity |

| Packaging & Shipping | Sealing compressed sofas in protective packaging, labeling and preparing for transport | Protects product in transit and eases handling |

Material Preparation: Foundation of Quality and Comfort

The first critical decision involves selecting materials that uphold comfort, durability, and compression capability.

Frame Materials:

- Options include lightweight metals like steel or aluminum, engineered wood composites, or high-strength polymers.

- Must support folding mechanisms (hinges, joints) for compression without warping or breaking.

- Surface finishes like powder coating or varnishing enhance durability and aesthetics.

Filling Materials:

- High-resilience polyurethane foams and memory foams dominate due to their elasticity and recovery after compression.

- Some designs incorporate latex or specialty blended foams for enhanced breathability and hypoallergenic properties.

- The foam density is carefully balanced to prevent sagging while allowing compressibility.

Fabric Choices:

- Outside fabrics include cotton blends, microfiber, velvet, linen, or performance textiles with stain resistance.

- Materials are chosen for stretchability to accommodate compression and quick recovery to smooth forms post-expansion.

- Breathability and ease of cleaning are also important consumer considerations.

Modular-Sofas.com selects materials after stringent testing to ensure long-term performance under repeated compression and use.

Frame Fabrication: Building the Sofa Skeleton

The frame supports the sofa structure, maintaining shape and bearing loads.

- Design for Modularity: Frames incorporate foldable joints or are produced in modular sections—this approach allows parts to collapse or detach, minimizing volume during packaging.

- Cutting and Assembly: Advanced CNC machines cut metal or wood components accurately. Skilled welders or assemblers join parts with mechanical fasteners and hinges.

- Surface Treatment: To resist corrosion and wear during compression cycles, frames receive powder coating or painting.

- Integration of Protective Elements: Padding or anti-scratch materials may be added to joints or contact points to prevent damage during folding and packing.

This phase ensures the frame remains lightweight yet robust, perfectly configured for the specific sofa model.

Foam Processing: The Core Cushioning System

Foams provide the necessary softness and support expected by consumers while needing to compress without damage.

- Cutting and Shaping: Large foam blocks are cut into seat cushions, backrests, armrests, and other components. Hot-wire cutters or CNC foam cutting machines ensure exact shapes.

- Compression Enhancement: Some foam parts may be pre-conditioned or processed to improve flexibility and compression recovery.

- Quality Assurance: Fillings are checked for uniform density, consistent thickness, and capability to regain shape after compression.

Proper foam technology is vital since it greatly affects both the sofa’s comfort and compression performance.

Fabric Cutting and Sewing: Tailoring the Exterior

The fabric encasements are custom-tailored to fit each sofa precisely and endure compression.

- Digital Pattern Design: CAD software generates cutting patterns tailored to sofa dimensions and stretch zones. This precision reduces fabric waste.

- Cutting: Automated or manual tools cut the fabric panels accordingly.

- Sewing: Expert seamstresses or robotic sewing machines assemble panels, creating covers with reinforced seams and opening mechanisms (zippers, Velcro) where needed.

- Testing: Elasticity, abrasion resistance, and colorfastness tests ensure the fabric will sustain compression cycles and normal use.

High craftsmanship here ensures aesthetics and durability.

Assembly: Bringing Components to Life

At the assembly stage, all elements come together.

- Filling Insertion: Foam cushions are inserted into their fabric covers with care to avoid damage or distortion.

- Fitting onto Frame: The covered cushions and frame sections are joined via fasteners or stretch fittings. Assembly ensures a snug fit, smooth lines, and structural integrity.

- Final Inspection: Dedicated personnel inspect the final sofa for comfort, fit, and readiness for compression.

Well-executed assembly is key to customer satisfaction and product longevity.

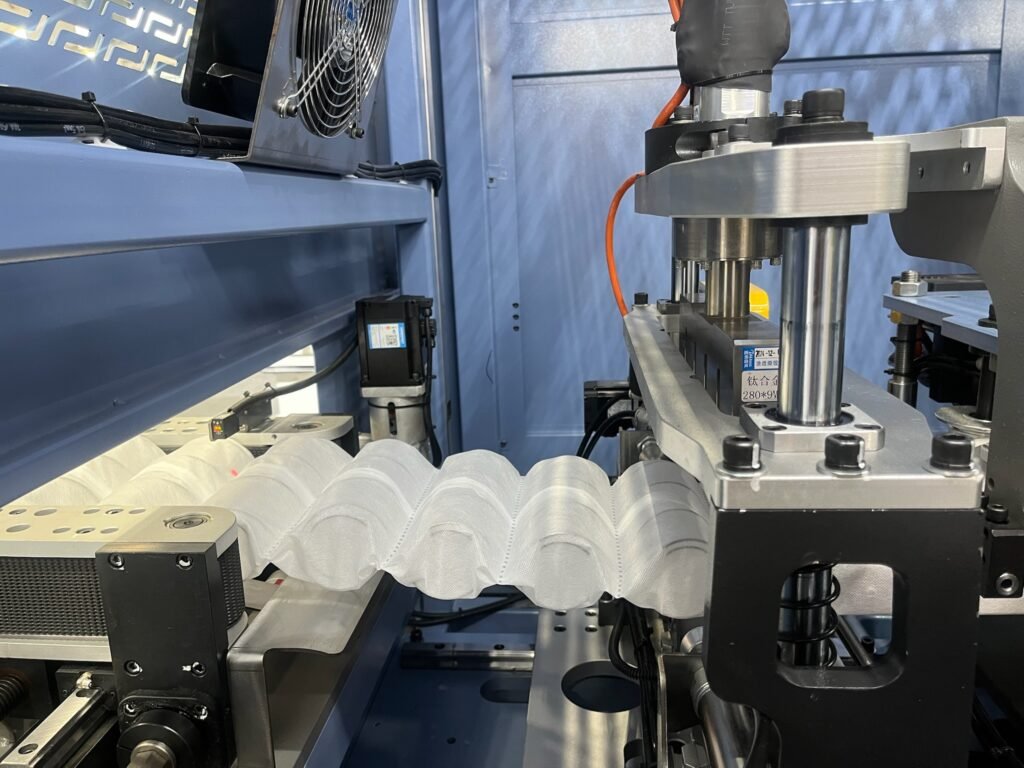

Compression Treatment: The Defining Innovation

Compression is the defining step that sets these sofas apart.

- Vacuum Compression: The fully assembled sofa is placed in an industrial vacuum chamber or compression machine. Air is evacuated to reduce volume drastically.

- Controlled Pressure & Timing: Pressure levels and compression duration are closely monitored to prevent permanent deformation or fabric damage.

- Rolling or Folding: Depending on design, the compressed sofa is rolled or folded tightly to fit into small, compact boxes.

This technology dramatically lowers shipping costs, reduces warehouse space and carbon footprint.

Packaging and Shipping: Protection and Convenience

After compression, products require secure packaging for transit.

- Packaging Materials: Thick, airtight plastic bags are used to maintain vacuum sealing. Outer cartons or custom boxes protect against mechanical shocks.

- Labeling: Packages bear clear information about model, dimensions, weight, and handling instructions to streamline warehouse management and consumer delivery.

- User Experience: Manuals or instructions accompany packages to help customers unpack and assemble sofas quickly.

The goal is safe delivery and effortless expansion, enhancing brand reputation.

Modular-Sofas.com and Excellence in Compressed Sofa Construction

Modular-Sofas.com exemplifies industry-leading compressed sofa manufacturing. With expertise encompassing each of the above stages, the company offers:

- Innovative Modular Designs: Sofas that can be customized and adapted for various spaces while still fully compatible with compression.

- Sustainable Materials: Use of eco-friendly foams, fabrics with low environmental impact, and recyclable packaging.

- Stringent Quality Controls: Ensuring sofas meet comfort, durability, and safety standards pre- and post-compression.

- Efficient Production Processes: Leveraging automation and skilled craftsmanship to maintain consistency and scalability.

These advantages enable Modular-Sofas.com to meet the growing global demand for efficient, stylish furniture solutions.

Summary Table: Compressed Sofa Construction Process

| Construction Phase | Key Activities | Importance |

|---|---|---|

| Material Preparation | Selecting foam, frame, and fabric materials with testing for compressibility | Ensures durability, comfort, and compression compatibility |

| Frame Fabrication | Cutting, folding/joint design, welding/assembling, and surface finishing | Provides flexible yet sturdy sofa skeleton |

| Foam Processing | Cutting foam to precise shapes; optional pre-compression conditioning | Maintains softness and elastic recovery |

| Fabric Cutting & Sewing | Digital pattern making, fabric cutting, sewing, and quality testing | Guarantees flexible, durable sofa covers |

| Assembly | Inserting fillings, fitting covers on frame, final inspection | Produces finished sofa ready for compression |

| Compression Treatment | Vacuum compression, rolling/folding, timing and pressure control | Reduces sofa volume up to 90% for efficient shipping |

| Packaging & Shipping | Vacuum sealing, protective boxing, labeling, and staging for logistics | Protects product and optimizes delivery |

Looking Ahead: The Future of Compressed Sofa Construction

As technology advances, compressed sofas continue to evolve. Future trends likely include:

- Smart Materials: Self-healing fabrics and foams that improve longevity under repeated compression.

- Sustainability: Greater use of bio-based, recyclable materials and carbon-neutral manufacturing.

- Customization Technologies: AI-driven design and modularity to tailor sofas exactly to consumer needs and spaces.

- Integration of Technology: Embedding smart home capabilities within modular compressed sofa structures.

Modular-Sofas.com stays committed to innovation, positioning itself at the cutting edge of these exciting developments.

Conclusion

The art and science of compressed sofa construction is a complex blend of material engineering, design innovation, and precise manufacturing techniques. Each stage—from material selection through vacuum compression and packaging—is rigorously controlled to deliver products that satisfy the modern consumer's demand for comfortable, stylish, and space-efficient furniture.

For companies like Modular-Sofas.com, mastery of this construction process combined with sustainable practices and modular customization creates unique value propositions in a highly competitive market. Understanding this detailed production guide offers valuable insights into how compressed sofas are expertly crafted to offer comfort, convenience, and environmental benefits for contemporary lifestyles.