In recent years, the furniture market has undergone significant transformations driven by evolving consumer demands for space efficiency, sustainability, and convenience. The sofa, being a centerpiece in any living room, has especially seen innovative developments such as compressed sofas. As specialists in modular sofas at modular-sofas.com, we understand that packaging plays a critical role in manufacturing, shipping, and user experience.

This article dives into the five key differences between compressed sofas and non-compressed (traditional) sofas in terms of product packaging, providing industry insights for manufacturers, retailers, and customers. Understanding these differences helps businesses optimize logistics and helps consumers make informed purchasing decisions.

Introduction: The Rise of Compressed Sofas

Traditional sofas have long been bulky, heavy, and difficult to transport. However, compressed sofas, innovated by leveraging high-density foam and modular designs, are revolutionizing how sofas are packaged, shipped, and handled. These sofas are compressed and vacuum-sealed into compact packaging, significantly reducing volume and costs.

Manufacturers operating as a compressed sofa factory can leverage these innovations for enhancing operational efficiency and improving customer satisfaction. Let’s explore the critical differences in detail.

1. Design Structure and Packaging Volume

The design and structural makeup of a sofa fundamentally dictate its packaging requirements.

Compressed Sofa Packaging

Compressed sofas employ modular design elements and high-resilience foam that can be temporarily deformed and vacuum-sealed to reduce size drastically. This compression allows the sofa to be rolled or folded into a compact package without damage.

- Modular sections are designed to snap together or align perfectly post-unpacking.

- Packaging materials are lightweight films or thin cardboard cartons.

Non-Compressed (Traditional) Sofa Packaging

Traditional sofas are crafted with rigid wooden or metal frames, thick cushions sewn on, and fixed upholstery, which makes compression impossible without damage.

- Packaged in bulky, sturdy boxes or crates.

- Additional cushioning materials (foam peanuts, air pillows) are used to protect the structure and fabric.

Packaging Volume Comparison Table

| Feature | Compressed Sofa | Traditional Sofa |

|---|---|---|

| Design Structure | Modular, made with high-density foam & fabric | Fixed frame, assembled with upholstery and cushions |

| Packaging Volume | Reduced by 70-80% through compression and rolling | Large, proportional to sofa size and shape |

| Space Efficiency | Ideal for tight spaces; small footprint | Requires large storage and transport space |

Summary: Compressed sofa packaging significantly reduces transportation and storage space requirements, improving overall supply chain efficiency.

2. Transportation and Logistics Efficiency

Packaging volume heavily influences logistics costs and handling ease.

Compressed Sofa Logistics Benefits

- Smaller cubic volume means more units per shipment, maximizing container/load efficiency.

- Packaging weight is lighter due to reduced bulk and minimal packing materials.

- Easier handling for warehouse staff and delivery personnel.

- Suitable for last-mile delivery challenges in urban environments with narrow staircases or doorways.

Traditional Sofa Logistic Challenges

- Bulky, heavy packaging requires special vehicles or multiple trips.

- Higher labor costs due to needing several people to load, unload, and maneuver furniture.

- Risk of damage due to fixed shapes and delicate upholstery exposed during transfers.

Transportation & Logistics Comparison Table

| Logistics Factor | Compressed Sofa | Traditional Sofa |

|---|---|---|

| Packing Weight | Light to moderate | Heavy |

| Vehicle Space Utilization | High (can stack and densely pack) | Low (boxes are large and bulky) |

| Handling Convenience | Easy for one or two people | Requires multiple handlers |

| Delivery Flexibility | High, adaptable to constrained urban conditions | Limited due to size and weight |

Summary: Compressed packaging decreases transportation cost per unit by maximizing shipping volume and improving last-mile delivery flexibility.

3. Packaging and Production Costs

Manufacturers consider packaging costs a significant portion of production overhead.

Compressed Sofa Costs

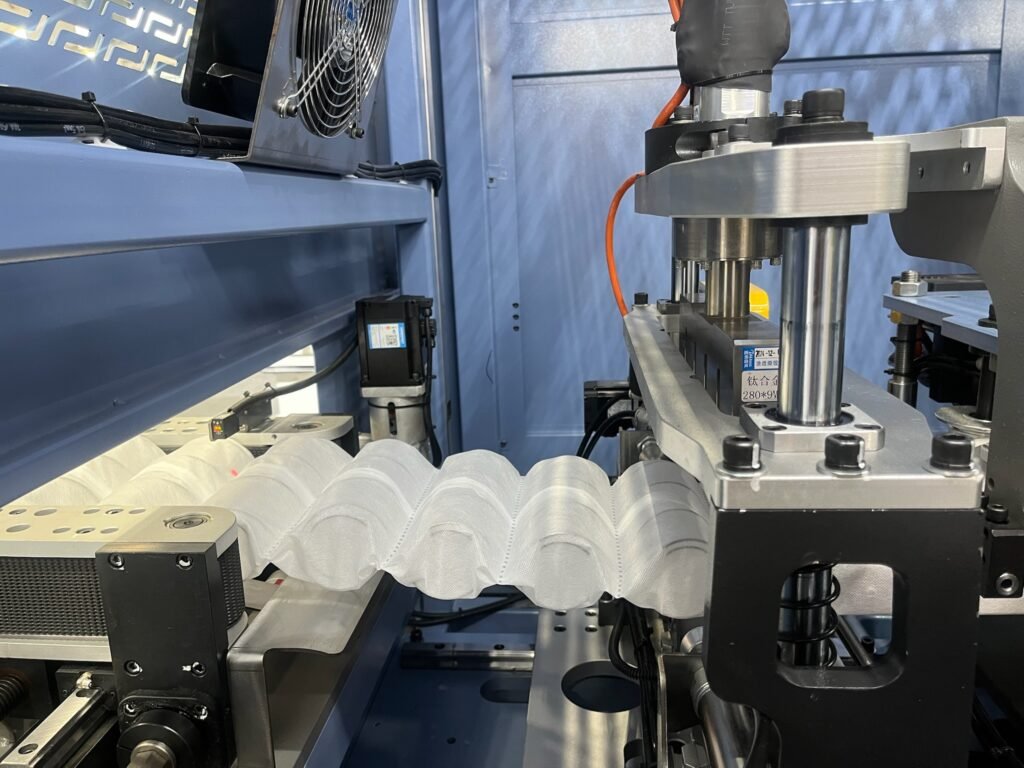

- Often uses vacuum-seal technology or compression rollers automated in factories.

- Requires less packaging material—mainly recyclable plastic films or thin cardboard.

- Lower labor cost due to automated or semi-automated packaging.

- Reduced storage space cuts warehousing costs.

Traditional Sofa Costs

- Heavy wooden crates, thick cardboard boxes, and protective foam dramatically increase costs.

- More labor-intensive packing processes.

- Larger warehouse footprint due to bulky packaging.

Packaging & Production Cost Comparison Table

| Cost Element | Compressed Sofa | Traditional Sofa |

|---|---|---|

| Packaging Materials | Minimal, lightweight plastic and cardboard | Large wooden crates and cushioning materials |

| Labor Cost for Packaging | Low to moderate, often mechanized | High, manual-intensive packaging |

| Storage Expense | Lower, due to compact packaging | Higher, large space required |

| Transportation Cost | Reduced, due to volume savings | High, due to bulky shipments |

Summary: Compressed sofas offer significant cost savings across packaging, storage, and transportation stages, enhancing factory and supply chain profitability.

4. Product Unpacking & Assembly User Experience

Customer satisfaction is greatly influenced by the unpacking and setup process.

Compressed Sofa Unpacking Experience

- Delivered in compact boxes or bags.

- Requires removing vacuum seal or unfolding.

- Foam cushions expand to full shape within minutes.

- Modular units connect simply, often without special tools.

- Transportation-friendly packaging benefits consumers who move frequently.

Traditional Sofa User Experience

- Delivered mostly pre-assembled or partially assembled.

- Ready to use immediately after delivery.

- Moving through doorways or staircases can be difficult.

- Heavy weights make handling tough for single individuals.

User Experience Comparison Table

| Experience Factor | Compressed Sofa | Traditional Sofa |

|---|---|---|

| Unpacking Time | 5-15 minutes for unfolding and expansion | Generally immediate; no unpacking needed |

| Assembly Difficulty | Low; typically modular and tool-free | None or minimal |

| Portability | High; easier to move and relocate | Low; bulky and heavy |

| Required Tools | Usually none or minimal | Usually none |

Summary: While compressed sofas require minor setup, the quick expansion and modular design enhance portability and convenience, meeting modern consumers’ preferences.

5. Environmental Impact and Sustainability

Sustainability is critical for manufacturers today and is becoming a major purchasing factor for consumers.

Compressed Sofa Environmental Advantages

- Smaller packaging volume means fewer trucks and less fuel consumption during transportation.

- Reduced use of heavy and non-recyclable packing materials.

- Compression reduces warehouse energy usage due to less space requirement.

- Many compressed sofa producers use eco-friendly foams and fabrics, often recyclable or biodegradable.

Traditional Sofa Environmental Concerns

- Packaging waste is larger due to crates, plastic wraps, foam, and bubble wrap.

- Increased carbon footprint from multiple trips and larger vehicles.

- Wood crates add to deforestation concerns if not sustainably sourced.

Environmental Impact Comparison Table

| Factor | Compressed Sofa | Traditional Sofa |

|---|---|---|

| Carbon Emissions | Lower, due to logistics efficiency | Higher due to larger shipments |

| Packaging Waste | Minimal; primarily thin films and recyclable materials | Considerable; heavy foam and wood waste |

| Material Sustainability | Often utilizes eco-friendly or recycled materials | Variable; often conventional materials |

| Recyclability | High recyclable content in packaging | Lower due to mixed materials |

Summary: Compressed sofa production aligns with growing sustainability demands, reducing environmental impact from manufacturing to delivery.

Comprehensive Comparison Overview

| Key Dimension | Compressed Sofa | Non-Compressed Traditional Sofa |

|---|---|---|

| Design & Packaging Volume | Modular, compressible foam, 70-80% smaller packaging volume | Rigid frame, large bulky boxes |

| Logistics Efficiency | High vehicle packing efficiency, easy handling | Low efficiency, requires larger freight and manpower |

| Packaging & Production Cost | Lower materials and labor cost | Higher packaging and labor costs |

| User Unpacking Experience | Requires unfolding and minimal assembly | Pre-assembled, no assembly needed |

| Environmental Impact | Reduced emissions, lower waste, recyclable packaging | Higher carbon footprint, more bulky packaging waste |

Why Choose a Compressed Sofa Factory like Modular Sofas?

At Modular Sofas, we specialize in innovating modular and compressed sofas using leading-edge manufacturing technology. Our compressed sofas:

- Are expertly designed for compact packaging and easy assembly.

- Feature high-quality materials ensuring comfort and durability.

- Reduce logistics costs, enabling competitive pricing.

- Support green initiatives for sustainable furniture production.

Our compressed sofa factory approach integrates design, packaging, and logistics seamlessly to deliver superior customer value worldwide.

Final Thoughts

The furniture industry is evolving with technological advancements and increased sustainability expectations. From packaging size to user experience and environmental impact, the differences between compressed and traditional sofas are profound.

For manufacturers, investing in compressed sofa designs and packaging innovations means unlocking higher efficiency, reducing costs, and expanding market reach. Retailers can offer convenient, affordable solutions to customers, and consumers benefit from easier delivery, setup, and eco-conscious products.

As a pioneer compressed sofa factory, Modular Sofas is committed to leading this transformation, delivering quality modular sofas that meet modern living demands.