A compressed sofa that breaks after one month? That’s not just disappointing—it damages your brand.

Quality control measures for compression sofas cover material selection, durability testing, ergonomics, surface inspection, assembly accuracy, and compliance with safety standards to ensure reliability and customer satisfaction.

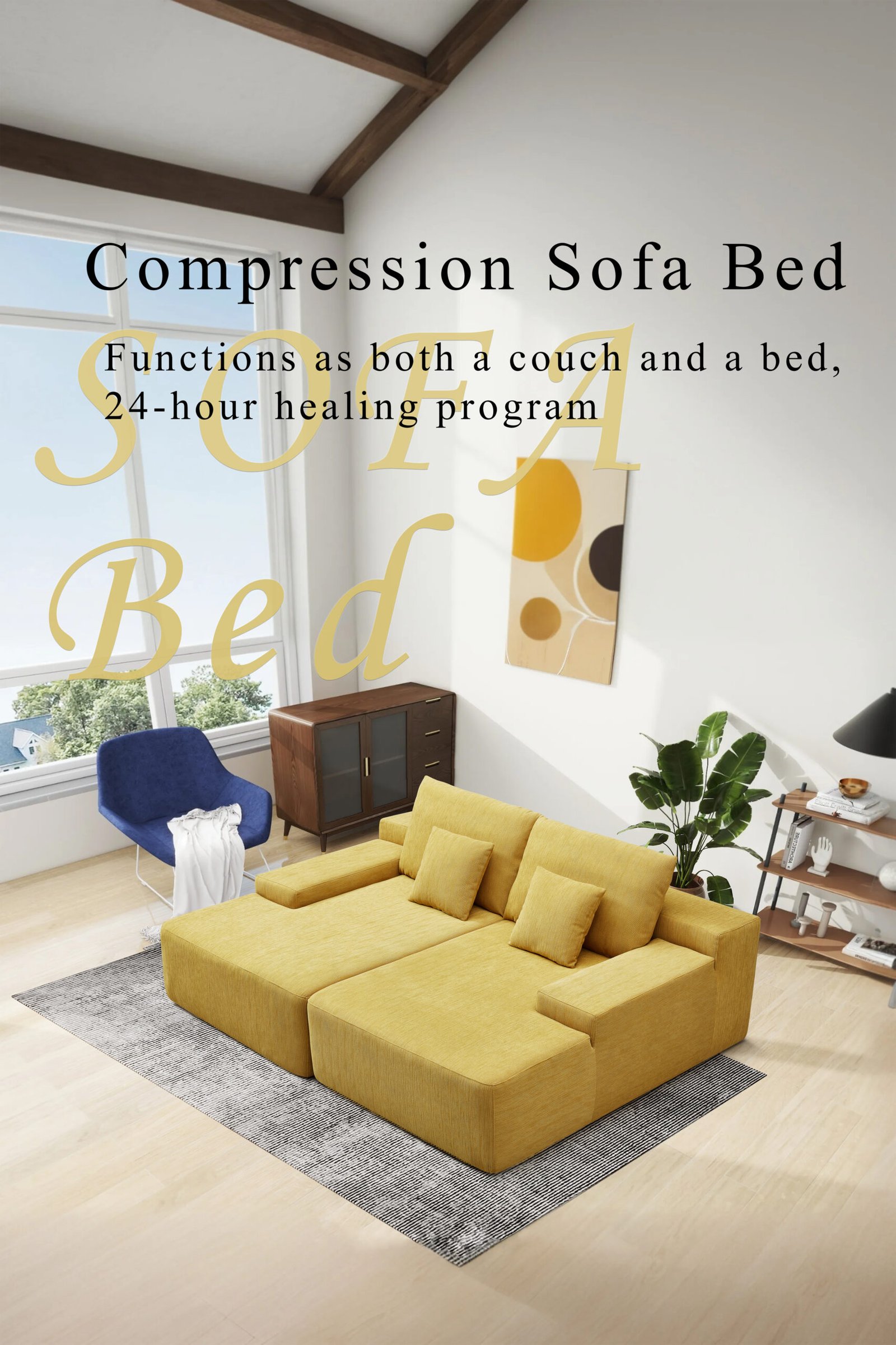

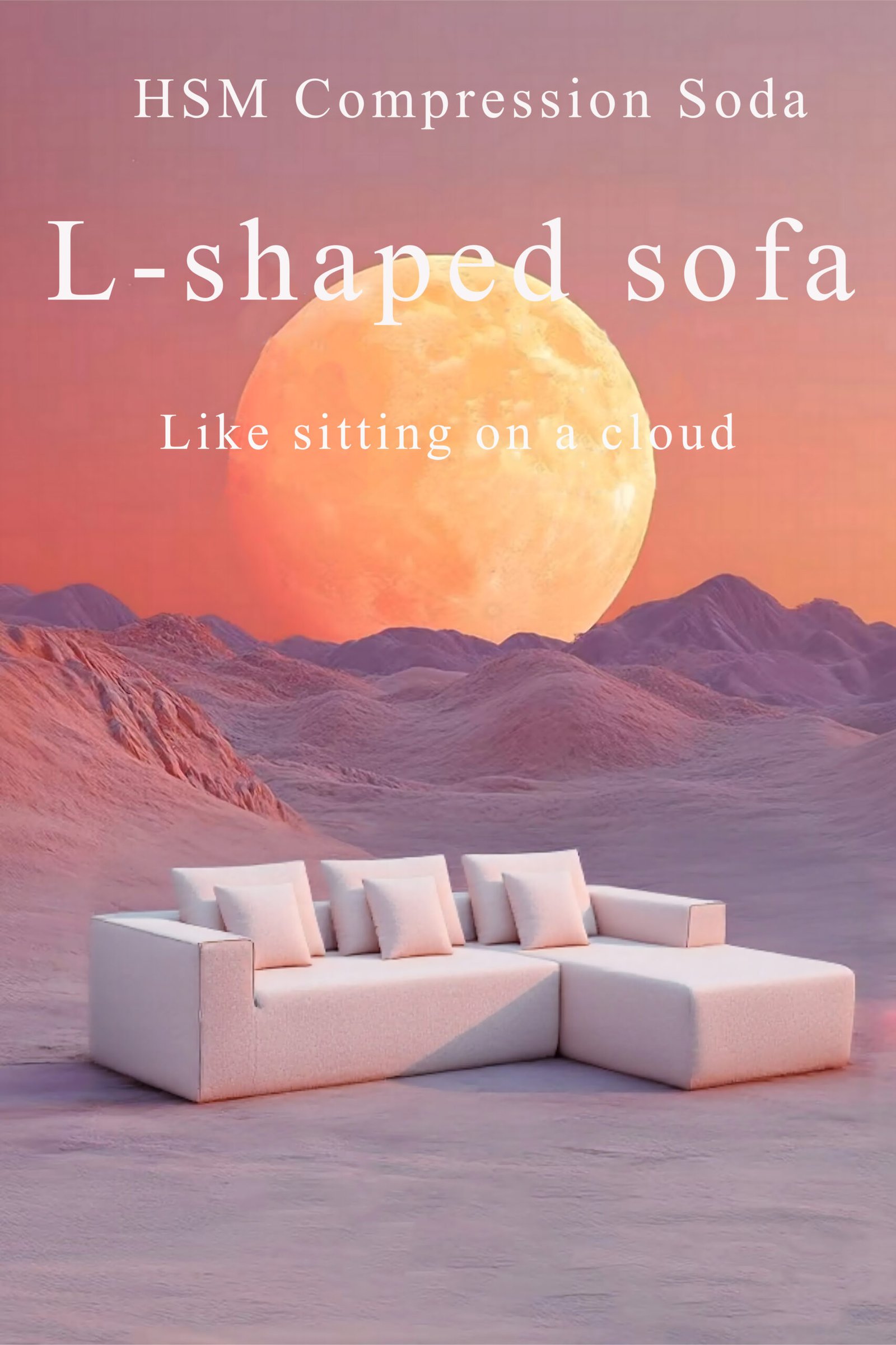

When we talk about compressed sofas, we’re not just talking about space-saving convenience. We’re talking about how well they hold up—through shipping, unpacking, and daily use. So in this post, I’ll walk you through every checkpoint we follow at HSM to ensure the sofas that reach you (or your customers) are durable, comfortable, and defect-free.

How do we verify the materials used in compression sofas?

Poor materials mean poor results—no matter how good the design.

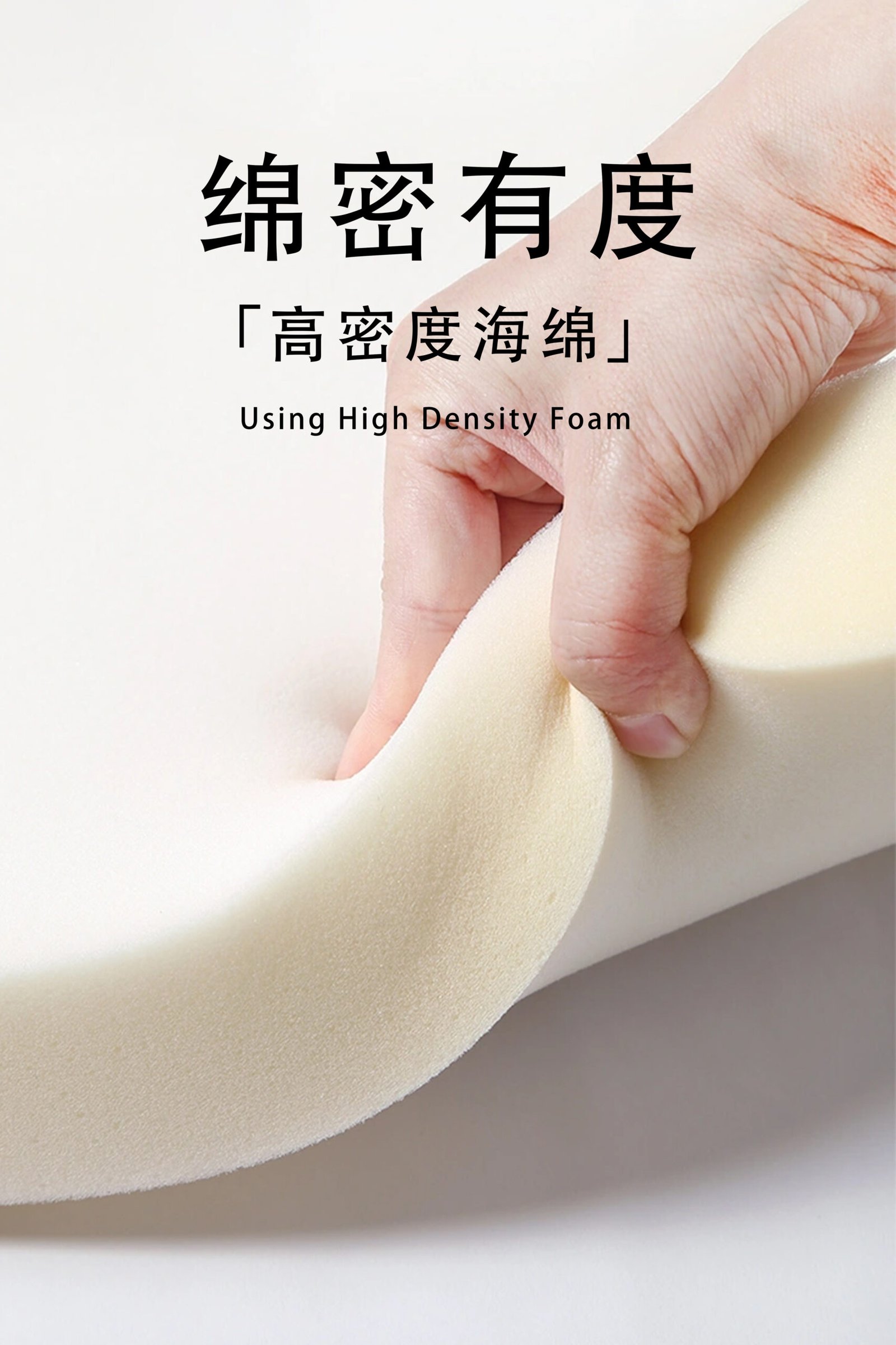

Material verification starts with testing the foam, fabric, and frame for density, durability, and structural integrity before production even begins.

Key Material Tests:

| Material | Test Method | Purpose |

|---|---|---|

| Foam | Compression-recovery cycles | Checks support and shape retention |

| Fabric | Martindale abrasion test | Measures wear resistance |

| Frame | Static load test | Confirms strength under heavy use |

| Color/Print | UV and washing fastness | Ensures visual consistency |

At HSM, we reject any batch of material that fails these tests—no compromise.

What happens during the manufacturing inspection?

Even with great materials, sloppy assembly ruins the end product.

Inspections are done at every stage—cutting, sewing, and final assembly—to catch issues early and maintain alignment with design specifications.

In-Process Inspections:

-

Cutting Stage:

- Are foam and fabric pieces within ±2mm tolerance?

- Are patterns aligned correctly?

-

Sewing Stage:

- Are stitches straight and evenly spaced?

- Is thread tension balanced?

-

Assembly Stage:

- Do frame joints lock tight?

- Is upholstery tensioned without wrinkles?

Each unit is signed off before moving to the next stage, which helps reduce rework costs and waste.

How is strength and durability tested?

You don’t want returns from customers saying “the seat collapsed in 3 weeks.”

We simulate long-term use with repetitive stress tests on both the frame and the cushions to ensure they last years—not weeks.

Strength Test Protocols:

| Component | Test Type | Simulation Target |

|---|---|---|

| Frame | Static load (1100N+) | 10+ years of adult use |

| Springs | 80,000 compression cycles | 8 years of bouncing & sitting |

| Foam Seat | Recovery rate check | Confirm bounce-back post-compression |

| Joints | Shear and tensile force test | Prevent loosening with use |

These tests ensure our sofas survive both the shipping process and daily wear in homes or showrooms.

Is the sofa ergonomically tested for comfort?

Even a strong sofa is useless if it feels awkward to sit on.

We evaluate seat depth, cushion softness, backrest angle, and real user feedback to ensure comfort and posture support.

Comfort Evaluation Steps:

- Use test groups to gather subjective feedback

- Measure lumbar support zones with pressure mapping

- Adjust foam layering for ideal support

- Compare seat and back height to ergonomic standards (e.g., 90°–100° recline)

When our users tell us a model feels “too upright” or “too soft,” we tweak the angles or foam density right away.

How is surface and finish quality controlled?

Wrinkled covers, mismatched colors, or itchy fabric? That’s a no-go.

Surface inspection checks color consistency, texture, and any visual or tactile defects to ensure a premium finish.

What We Inspect:

- Color matching between parts and batches

- No pilling or loose threads

- Seam alignment and pattern continuity

- Surface feel (smooth, plush, consistent)

We use swatches and control samples for side-by-side comparison under consistent lighting.

Are dimensions checked accurately?

Too long and it won’t fit in the box. Too short and it won’t feel right.

Dimensional accuracy is verified with tools like laser meters and digital calipers before and after compression to guarantee assembly precision.

| Dimension | Tolerance Range | Tool Used |

|---|---|---|

| Frame Length | ±3mm | Digital ruler |

| Seat Depth | ±2mm | Caliper |

| Back Height | ±2mm | Laser level |

| Packaging Volume | Exact requirement | Volume scanner |

Dimensional checks reduce waste, return risk, and ensure compatibility with customer expectations.

How are the joints and assembly strength validated?

Nothing worse than a squeaky or wobbly sofa on Day 1.

We stress-test joint areas with tension and pressure to ensure all connections are locked and loaded.

Tests include:

- Tensile pull test: Simulates backrest movement pressure

- Drop test (30cm x 3 times): Mimics accidental handling impact

- Shake test: Simulates years of motion

Any looseness triggers a redesign of the fastening structure or material selection.

Are safety and compliance standards followed?

Non-compliance isn’t just risky—it can block your product at customs.

We follow strict regional safety standards like CA TB117, EN 12520, or REACH for fire resistance, chemical limits, and child safety.

Common compliance checks:

- Fire-retardant certification for upholstery foam

- Formaldehyde and VOC testing for adhesives

- Mechanical safety reports for structural integrity

We provide full documentation on request to support certifications and global exports.

How is packaging and shipping quality maintained?

Crushed boxes and torn wraps kill customer trust—fast.

Compression packaging is checked for seal integrity, impact protection, and moisture resistance to ensure safe arrival.

Checklist before dispatch:

- Is vacuum seal fully intact?

- Are foam guards placed at weak corners?

- Does the outer box pass drop and crush tests?

- Is the barcode properly attached?

We also test how long the sofa takes to recover after unpacking—and flag any delay over 30 minutes.

Conclusion

Quality control isn’t just a checklist. It’s the backbone of trust in every compressed sofa we build. With solid materials, smart testing, and careful packaging, your sofa arrives strong, safe, and ready for years of comfort.