Compressed sofas have revolutionized the furniture industry with their compact design and easy transportation. But what exactly goes into making these space-saving sofas?

A compressed sofa consists of a sturdy frame, comfortable cushion filling, and durable upholstery fabric. These materials are designed to withstand compression during packaging while maintaining comfort and functionality.

Understanding the components of a compressed sofa helps consumers make informed purchasing decisions. Let’s break down the key materials used.

What Are Compressed Sofa Frames Made Of?

A sofa’s durability and stability start with its frame. The frame provides structural support and determines how long the sofa will last.

Compressed sofa frames are typically made from hardwood, plywood, metal, or engineered wood, each offering different benefits in terms of strength and longevity.

Common Frame Materials

| Material | Benefits | Drawbacks |

|---|---|---|

| Hardwood (Oak, Maple, Walnut) | Strong, long-lasting, resists warping | Heavy and expensive |

| Plywood | Affordable, lightweight, stable | Less durable than hardwood |

| Metal (Steel, Aluminum) | Lightweight, modern look, resistant to bending | Can be prone to rust if not treated |

| Engineered Wood (MDF, Particleboard) | Budget-friendly, easy to shape | Less durable, susceptible to moisture damage |

High-quality compressed sofas often use a combination of metal and wood to balance strength and weight.

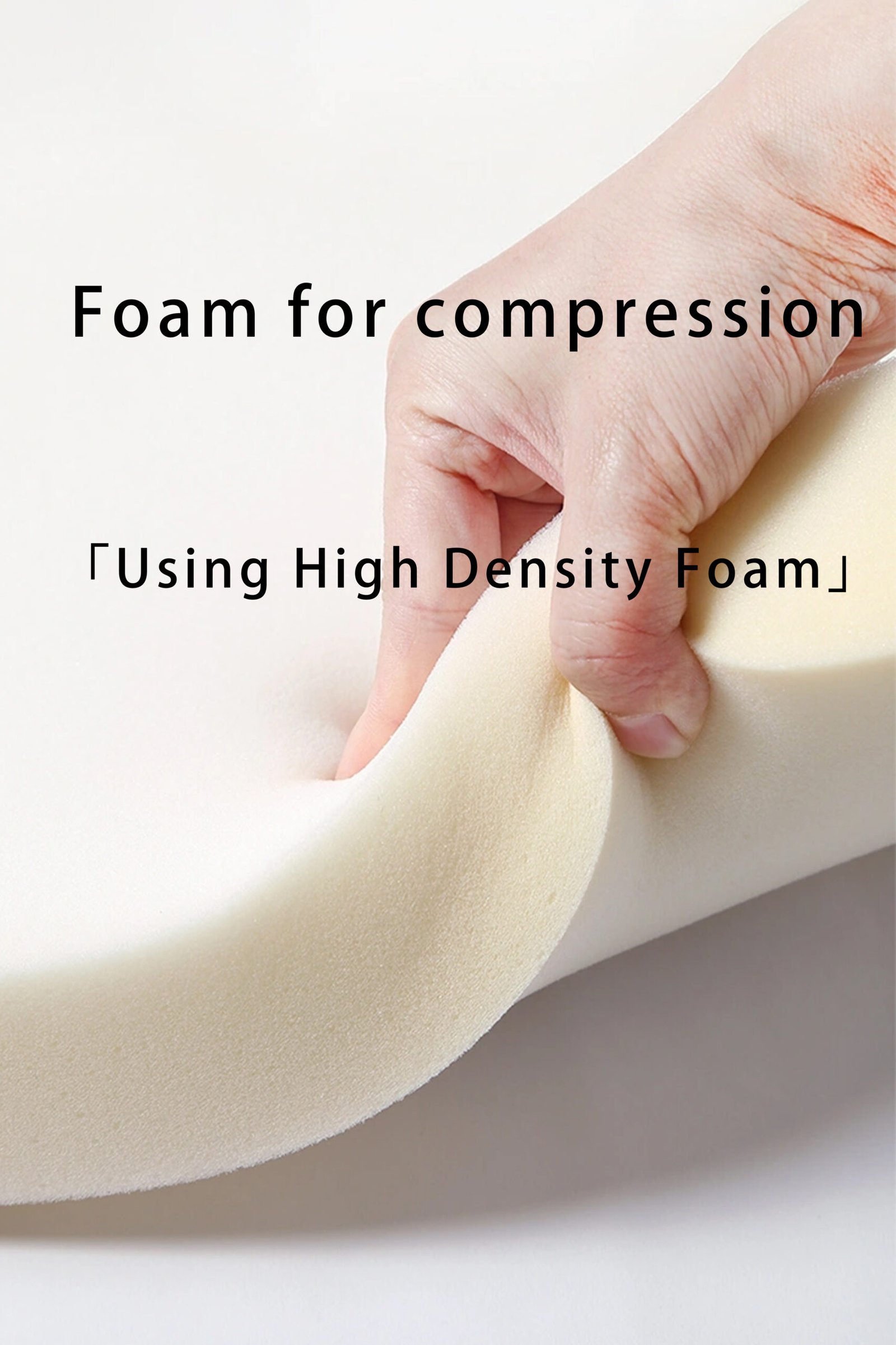

What Type of Cushion Filling Do Compressed Sofas Use?

A sofa’s comfort depends largely on its cushion filling. Since compressed sofas must regain their shape after unpacking, the right cushion material is crucial.

Compressed sofas commonly use high-density foam, memory foam, polyester fiber, or down feathers for cushioning.

Types of Cushion Fillings

| Cushion Filling | Comfort Level | Durability |

|---|---|---|

| High-Density Foam | Firm support, retains shape well | Long-lasting, but can feel stiff |

| Memory Foam | Contours to the body, reduces pressure points | Softens over time |

| Polyester Fiber | Plush and lightweight | Flattens quicker than foam |

| Down Feathers | Luxurious softness, best for lounging | Requires regular fluffing |

Foam-based cushions are the most common choice for compressed sofas as they are durable and can expand back to their original form after compression.

What Upholstery Fabrics Are Used for Compressed Sofas?

The upholstery fabric affects the sofa’s aesthetics, durability, and ease of maintenance.

Compressed sofas are available in materials like leather, faux leather, microfiber, linen, and velvet, each with unique benefits.

Common Upholstery Fabrics

| Fabric | Pros | Cons |

|---|---|---|

| Leather | Durable, easy to clean, luxurious look | Expensive, requires conditioning |

| Faux Leather | Affordable alternative, resistant to stains | Can crack over time |

| Microfiber | Soft, stain-resistant, pet-friendly | Can attract dust |

| Linen | Natural, breathable, stylish | Wrinkles easily, harder to clean |

| Velvet | Elegant, plush feel | Requires delicate care |

For durability and easy maintenance, microfiber and faux leather are popular choices in compressed sofas.

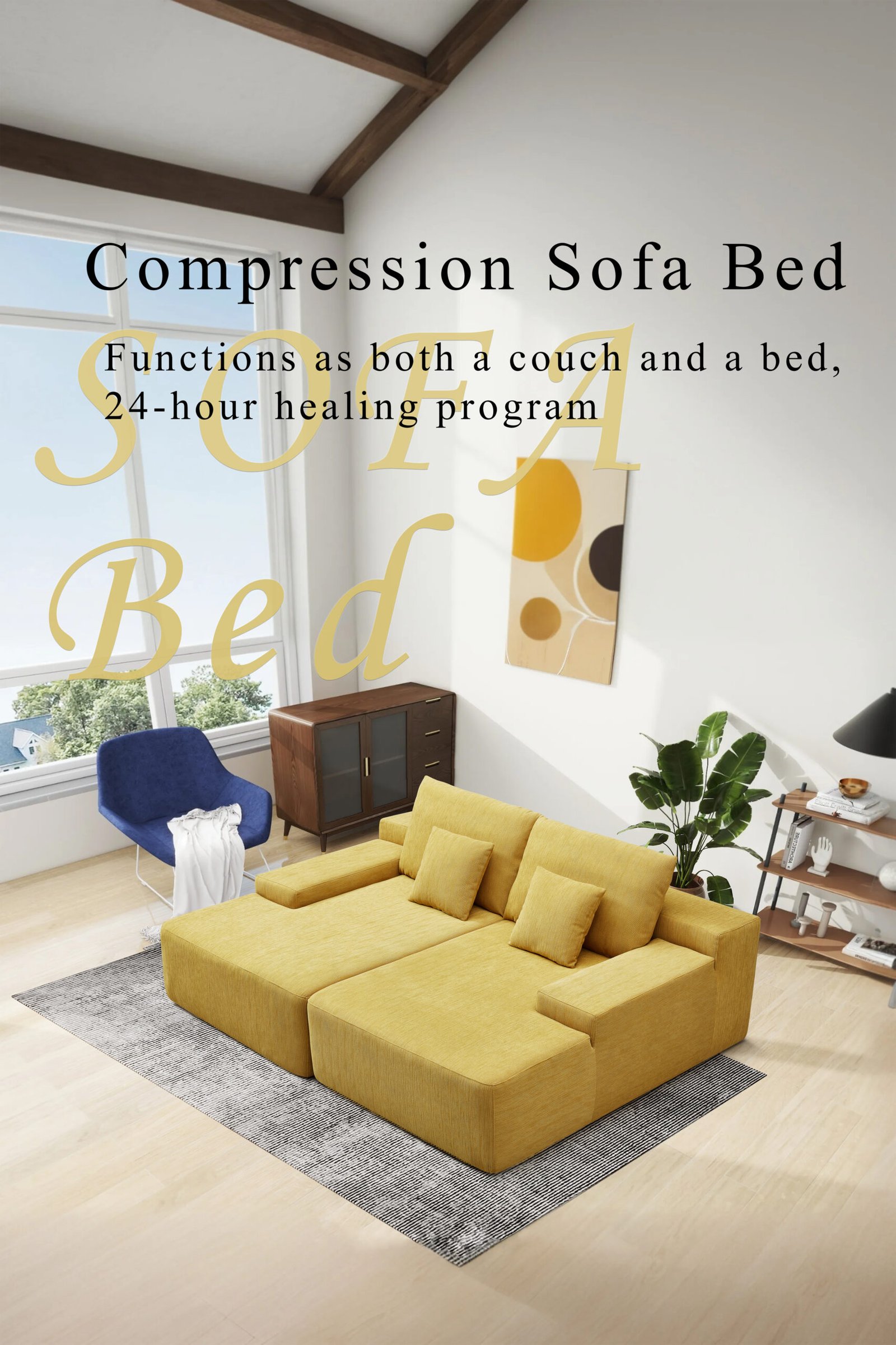

How Does Compression Technology Work in Sofas?

Compressed sofas are designed to be vacuum-packed for easy transportation. But how does this process work?

Compression technology involves vacuum sealing and mechanical compaction, reducing the sofa’s size for shipping while ensuring it regains its shape upon unpacking.

Compression Process

- Vacuum Sealing: Air is removed from foam cushions to shrink their volume.

- Frame Disassembly: Frames are designed to be collapsible or modular.

- Compact Packaging: Components are packed in a tight box, reducing shipping costs.

- Expansion Upon Unpacking: Once opened, cushions gradually regain their full form.

This innovative process makes compressed sofas lightweight, easy to ship, and space-efficient.

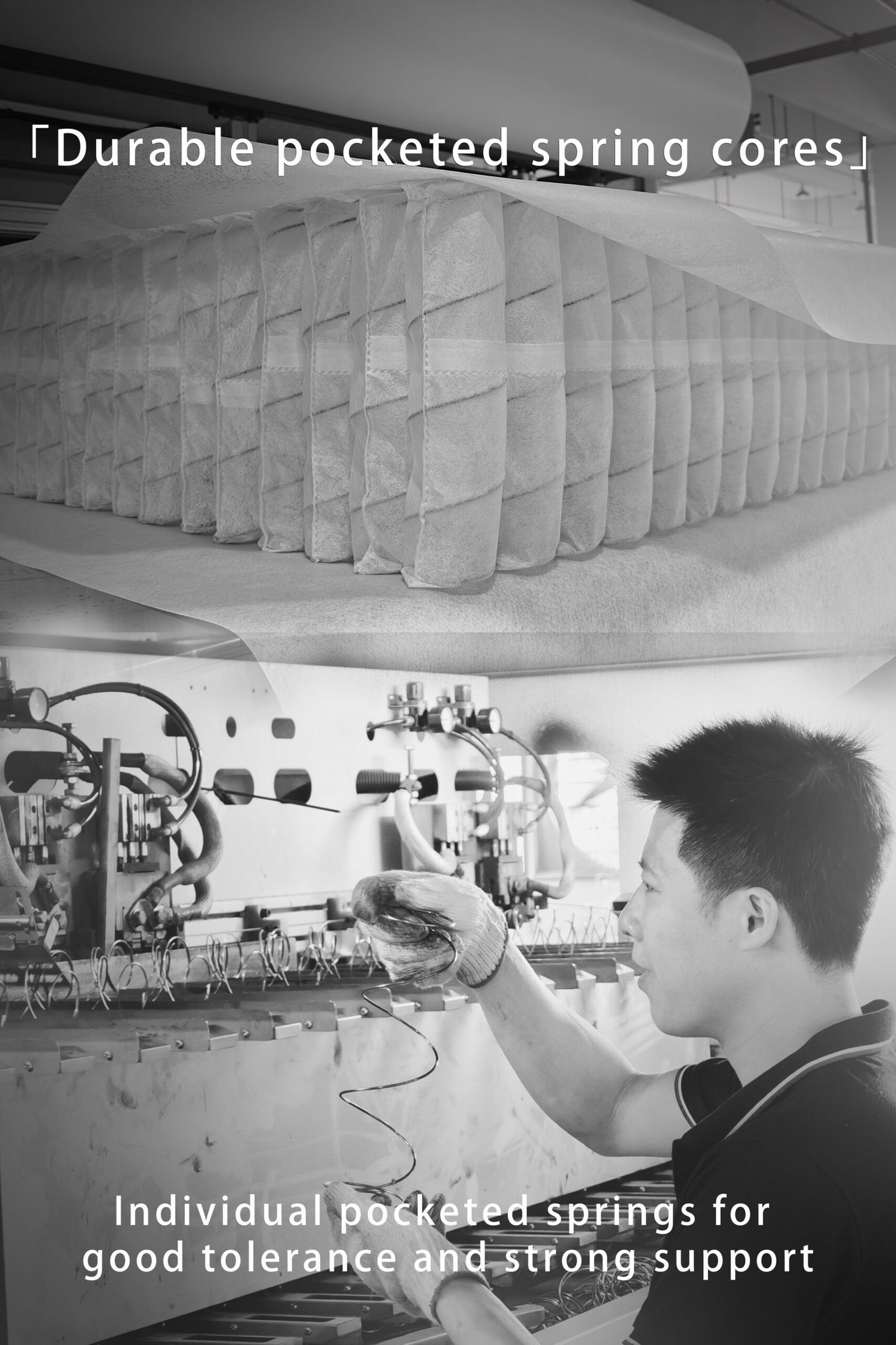

Are Compressed Sofas as Durable as Traditional Sofas?

Many buyers worry that compressed sofas won’t last as long as traditional sofas.

While compressed sofas use durable materials, their lifespan depends on the quality of construction and materials used.

Factors Affecting Durability

- Frame Strength: Hardwood and metal frames last longer than particleboard.

- Cushion Quality: High-density foam cushions hold their shape better over time.

- Upholstery Type: Leather and microfiber fabrics are more resistant to wear and tear.

Well-constructed compressed sofas can last 5-10 years, making them a reliable furniture option.

Conclusion

A compressed sofa is made of **a sturdy frame (wood or metal), resilient cushion filling (foam or fiber), and