Compressed sofas are a marvel of modern engineering, designed to maximize efficiency and minimize space. But how exactly do they achieve their compact size?

Compressed sofas achieve their compact size through a process that combines disassembly (if necessary), protective wrapping, vacuum sealing, and compression using hydraulic machines.

This innovative method ensures that sofas are delivered in a space-saving form without compromising their structural integrity. Let’s explore this fascinating process in detail.

What Is the Key to Reducing a Sofa’s Volume?

The key to compressing a sofa lies in careful preparation and the use of specialized equipment. Every step is crucial to ensure the sofa maintains its quality after being unpacked.

The process involves flattening the sofa’s cushioning and frame, removing air from the packaging, and securely sealing the unit to keep it compact.

This ensures a balance between reducing size and maintaining functionality, making the sofa ready for efficient shipping.

Factors That Contribute to Volume Reduction

- Material Flexibility: Sofas made with compressible foam and springs are ideal for this process.

- Protective Layers: Wrapping ensures no damage occurs during compression.

- Vacuum Technology: Removing air significantly decreases the volume.

Key Statistics:

| Stage | Volume Reduction |

|---|---|

| Wrapping & Sealing | 10-15% |

| Vacuum Compression | 40-50% |

| Final Hydraulic Pressing | Up to 70% |

How Does the Compression Process Work?

The compression process uses advanced technology to minimize sofa size without damaging its materials. Let’s break it into steps:

1. Wrapping: Protective layers like bubble wrap or foam are applied to cushion the sofa.

2. Sealing: A vacuum bag encases the sofa to remove air.

3. Compression: Hydraulic presses apply pressure to reduce thickness and volume.

4. Boxing: The compact unit is placed in a sturdy box for transportation.

Role of Machines in Compression

- Vacuum Sealers: Remove air to shrink the packaging.

- Hydraulic Compressors: Apply even pressure to flatten the sofa’s cushioning and frame.

- Automated Wrappers: Ensure quick and precise application of protective layers.

Ensuring Quality After Compression

To maintain quality, manufacturers use compression-resistant materials, reinforced packaging, and proper pressure levels. This ensures the sofa looks and feels perfect once unpacked.

Why Are Certain Materials Better for Compression?

Not all sofas can undergo compression. The materials used play a vital role in determining how compact a sofa can become.

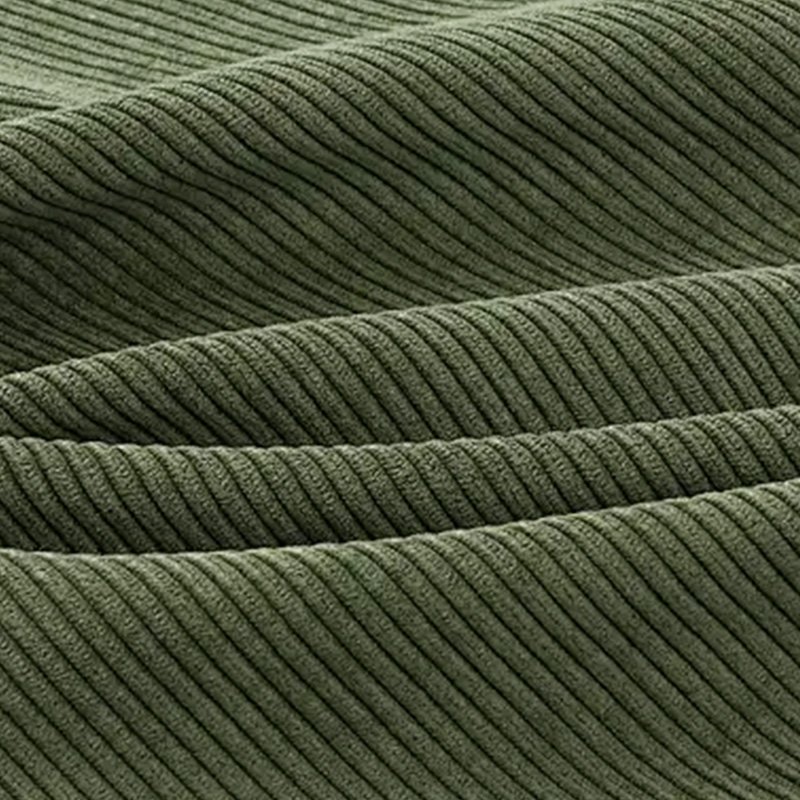

Flexible materials like memory foam, high-density polyurethane, and pocket springs are ideal because they compress easily and regain their shape upon unpacking.

These materials are designed to endure pressure without losing their structural integrity.

Material Considerations

- Foam Quality: Softer foams compress more but must retain durability.

- Spring Design: Pocket springs perform well because they are independent and resilient.

- Frame Construction: Modular frames or metal structures ensure easy assembly after compression.

Comparison of Materials:

| Material | Compression Suitability |

|---|---|

| High-Density Foam | Excellent |

| Memory Foam | Excellent |

| Pocket Springs | Very Good |

| Wooden Frames | Limited |

How Do Compressed Sofas Expand After Delivery?

When customers receive their compressed sofa, it needs to return to its original size. This process is simple and ensures convenience for users.

Compressed sofas expand by removing them from their packaging and allowing air to naturally refill the vacuumed cushioning. Some models may include simple assembly steps.

This re-expansion is a key feature of compressed furniture, offering a seamless customer experience.

Steps for Unpacking:

- Carefully cut the vacuum-sealed bag.

- Allow the sofa to regain its shape (usually within 24-48 hours).

- Assemble any modular parts if necessary.

Tips for Customers

- Avoid sharp objects when opening the package.

- Let the sofa expand in a well-ventilated space.

- Follow assembly instructions for optimal results.

Conclusion

Compressed sofas achieve their compact size through innovative engineering and advanced technology. From material selection to hydraulic compression, every step ensures a space-saving and efficient solution for manufacturers and consumers alike.