Introduction

As the compress sofa market expands rapidly—driven by urbanization, e-commerce, and the demand for space-saving solutions—B2B buyers, manufacturers, and distributors must pay close attention to the foam types used in these products. Just as essential oil brands carefully select bottle sizes to balance preservation, branding, and consumer needs1, choosing the right foam type is crucial for ensuring comfort, durability, and logistics efficiency in compress sofas. This guide provides a comprehensive overview of foam types in compress sofas, their applications, and how B2B stakeholders can leverage foam selection for product differentiation and market success in 2025 and beyond.

Why Foam Type Matters More Than You Think

The choice of foam in compress sofas directly impacts:

- Comfort and Support: The foam’s density and resilience determine the sofa’s seating experience.

- Compression and Recovery: Only certain foams can withstand vacuum compression and reliably return to their original shape.

- Durability and Lifespan: High-quality foams resist sagging, deformation, and breakdown, ensuring long-term value for B2B clients.

- Logistics and Packaging: The right foam type optimizes compression ratios, reducing shipping costs and storage space.

Selecting the optimal foam is not just a technical decision—it’s a strategic move that shapes customer satisfaction and brand reputation.

Exploring Common Foam Types in Compress Sofas and Their Uses

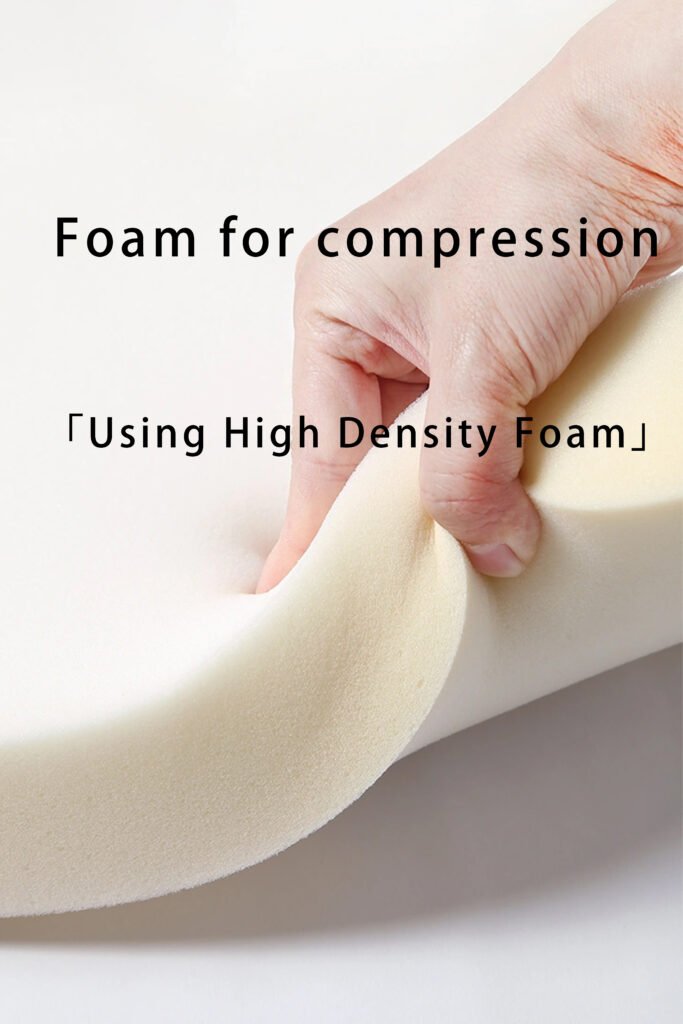

1. High-Resilience (HR) Polyurethane Foam

- Features: Excellent bounce-back, high durability, and superior comfort.

- Applications: Premium compress sofas, modular seating, and hospitality projects.

- B2B Advantage: Ensures sofas survive repeated compression cycles and offer a luxurious feel, supporting premium positioning.

2. Memory Foam

- Features: Conforms to body shape, relieves pressure points, and provides a plush seating experience.

- Applications: Sofa beds, sleeper sofas, and ergonomic seating.

- B2B Advantage: Appeals to health-conscious and luxury markets, but requires careful engineering to balance compression recovery and long-term shape retention.

3. Conventional Polyurethane Foam

- Features: Cost-effective, moderate comfort, and good compressibility.

- Applications: Entry-level compress sofas, budget-friendly models, and high-volume projects.

- B2B Advantage: Allows for competitive pricing and high-volume supply, but may have shorter lifespan compared to HR or memory foam.

4. Latex Foam

- Features: Naturally resilient, hypoallergenic, and highly durable.

- Applications: Eco-friendly and sustainable compress sofas, high-end hospitality, and wellness-focused projects.

- B2B Advantage: Supports green marketing and appeals to clients with sustainability goals, aligning with current eco-friendly furniture trends2.

5. Hybrid Foam Blends

- Features: Combines properties of HR foam, memory foam, and latex for tailored performance.

- Applications: Custom compress sofas for niche markets or specific B2B requirements.

- B2B Advantage: Enables fine-tuning of comfort, support, and compression characteristics for differentiated product lines.

How to Choose the Right Foam Type for Your B2B Needs

For Retailers & Wholesalers

- Market Positioning: Match foam type to your target segment—HR and latex for premium, conventional PU for value markets.

- Customer Feedback: Monitor returns and reviews to identify foam-related satisfaction or issues.

- Sustainability: Offer latex or recycled-content foams to meet growing demand for eco-friendly options2.

For Manufacturers

- Compression Testing: Rigorously test foam samples for recovery rate, density, and durability under vacuum compression.

- Customization: Provide B2B clients with foam selection options to tailor sofas for specific markets or projects.

- Quality Control: Implement strict standards to ensure consistent foam performance across production runs.

For Distributors

- Bulk Orders: Stock a range of foam types to serve diverse B2B buyers, from budget to luxury.

- Education: Equip sales teams with knowledge about foam benefits and trade-offs to support consultative selling.

Custom Foam Solutions for Unique Market Needs

Just as essential oil brands offer custom bottle sizes for branding and functionality1, compress sofa suppliers can differentiate with custom foam blends, densities, and certifications (e.g., CertiPUR-US, OEKO-TEX). This enables B2B clients to create exclusive product lines, address unique project requirements, and strengthen their market position.

Market Trends: Sustainability, Health, and Performance

- Eco-Friendly Foams: Demand for recycled, plant-based, or biodegradable foams is rising, especially in Europe and North America2.

- Health & Wellness: Anti-microbial and hypoallergenic foams are gaining traction in hospitality and healthcare sectors.

- Performance Innovation: New foam technologies focus on improved airflow, temperature regulation, and enhanced compression recovery.

Conclusion

Foam selection is a critical factor in the success of compress sofas for the B2B market. By understanding the properties, applications, and advantages of each foam type, stakeholders can make informed decisions that boost product quality, customer satisfaction, and brand differentiation. As the market evolves, staying ahead of foam technology trends and offering custom, sustainable solutions will be key to long-term success.