Introduction

In the competitive world of furniture manufacturing and distribution, packaging is more than just a protective cover—it is a strategic tool that shapes brand identity, optimizes logistics, and enhances customer satisfaction. For B2B stakeholders such as manufacturers, wholesalers, and distributors, the packaging of compress sofas must balance durability, cost-efficiency, sustainability, and market appeal. This guide explores ten critical considerations to ensure your compress sofa packaging stands out in 2024 and beyond, helping your business secure a competitive edge in the global furniture market.

Brand Identity and Visual Impact

Packaging is the first touchpoint between your brand and your clients. For compress sofas, a visually appealing, well-branded carton can reinforce your company’s identity and communicate professionalism to B2B buyers. Incorporate your logo, consistent color schemes, and clear messaging to make your packaging instantly recognizable and memorable in showrooms or during delivery12.

Understanding Your Target Market

Know the needs and preferences of your B2B clients—whether they are retailers, e-commerce platforms, or hospitality buyers. Consider if your target audience values eco-friendly materials, quick assembly, or premium finishes. Tailor your packaging features and communication to address these priorities, fostering stronger business relationships and repeat orders.

Packaging Structure and Layering

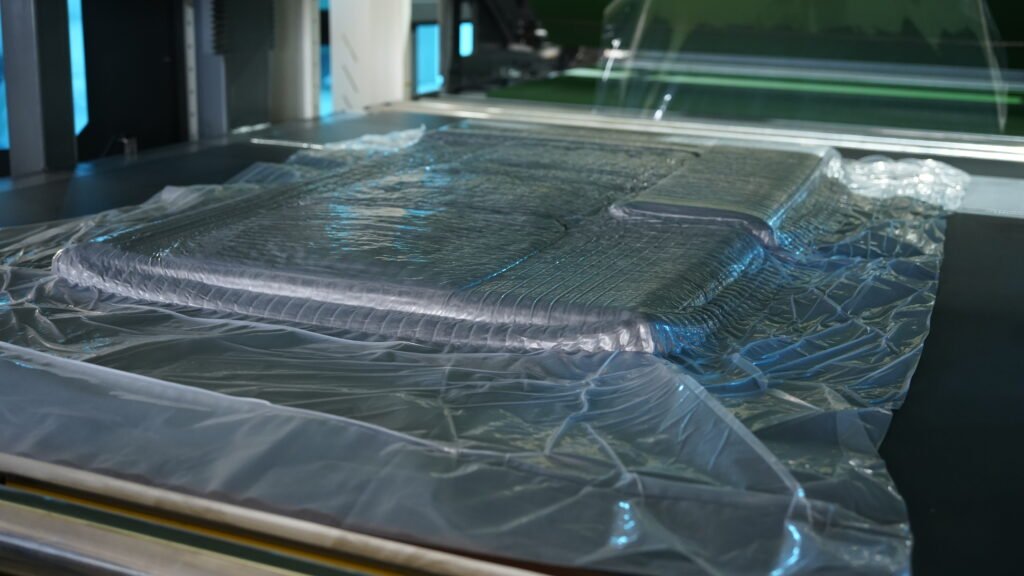

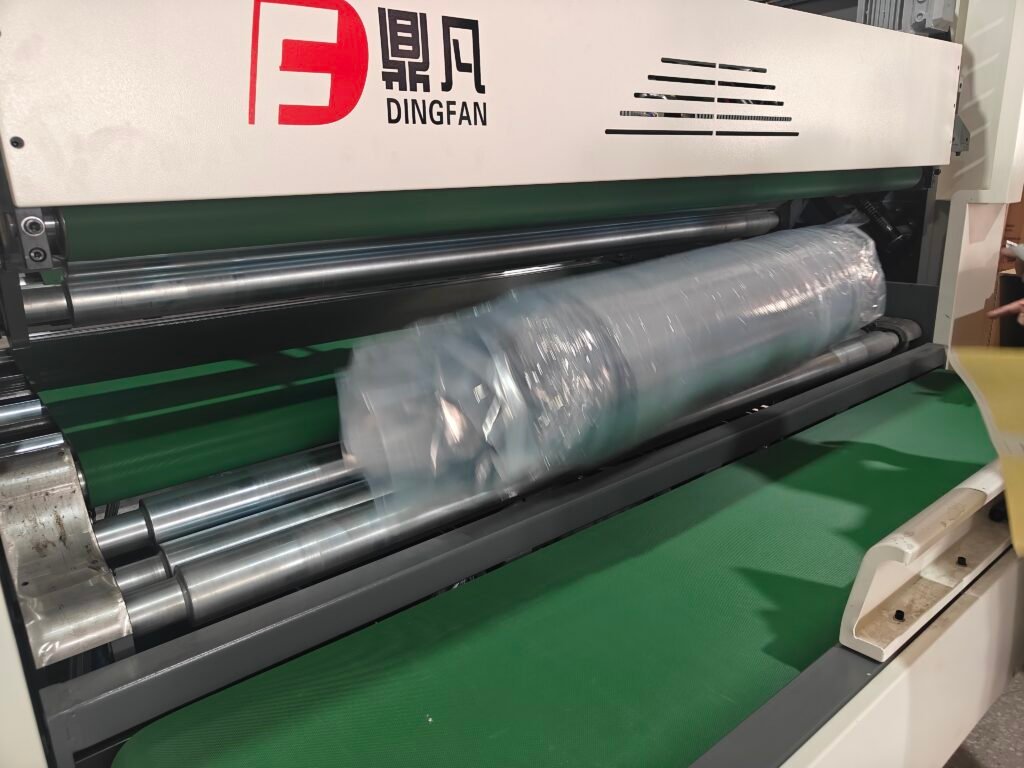

Effective compress sofa packaging typically involves multiple layers: an outer carton for protection and branding, inner packaging (such as vacuum-sealed bags and foam inserts) for shock absorption, and sometimes tertiary packaging for bulk shipments. Each layer must be engineered for maximum protection and efficiency, especially during long-distance transport and warehousing1.

Material Selection and Sustainability

Choose packaging materials that balance strength, weight, and environmental impact. Corrugated cardboard, biodegradable plastics, and recycled materials are increasingly favored by B2B buyers seeking to meet corporate sustainability targets. Highlighting your use of eco-friendly materials can enhance your appeal to environmentally conscious partners.

Compliance and Regulatory Requirements

Ensure your packaging meets all relevant regulations for labeling, safety, and materials—especially for export markets. Include clear handling instructions, product information, and any required certifications. Accurate and compliant packaging builds trust and reduces the risk of customs delays or legal issues1.

Cost Optimization and Budget Control

Packaging costs directly impact your bottom line. Evaluate material choices, design complexity, and supplier options to achieve a balance between cost and quality. Bulk purchasing and standardized sizes can help reduce expenses, but never compromise on protection or brand presentation, as these factors influence B2B customer satisfaction and repeat business1.

Consistency and Cohesive Branding

Maintain a consistent look and feel across all your compress sofa packaging. Cohesive branding—through colors, fonts, and design elements—reinforces your company’s identity and makes your products easily identifiable in warehouses and retail environments. Consistency also streamlines logistics and inventory management for your B2B partners.

Information Clarity and Labeling

Clear, informative labeling is essential for B2B logistics and end-user assembly. Include product codes, assembly instructions, safety warnings, and destination details. Consider adding QR codes for digital manuals or video guides, enhancing the unboxing and setup experience for your business clients.

Logistics and Transportation Efficiency

Design your packaging for maximum shipping and storage efficiency. Optimize carton dimensions for container loading, pallet stacking, and warehouse racking. Lightweight, compact packaging reduces freight costs and minimizes handling risks—key concerns for wholesalers and distributors managing large-scale shipments.

Health, Safety, and Product Protection

Prioritize packaging solutions that safeguard the sofa’s structural integrity and prevent damage from moisture, impacts, or contamination. Use protective inner layers such as foam inserts or air pillows, and ensure all materials are safe for prolonged contact with upholstery fabrics. Rigorous quality checks and secure sealing methods are essential to maintain product quality throughout the supply chain.

Conclusion

Thoughtful packaging design is a cornerstone of success in the B2B furniture industry. By considering brand identity, target market needs, material sustainability, regulatory compliance, and logistics efficiency, you can create compress sofa packaging that not only protects your product but also elevates your brand and streamlines your supply chain. In 2025 and beyond, these ten considerations will help your business stand out and thrive in a dynamic, global marketplace.