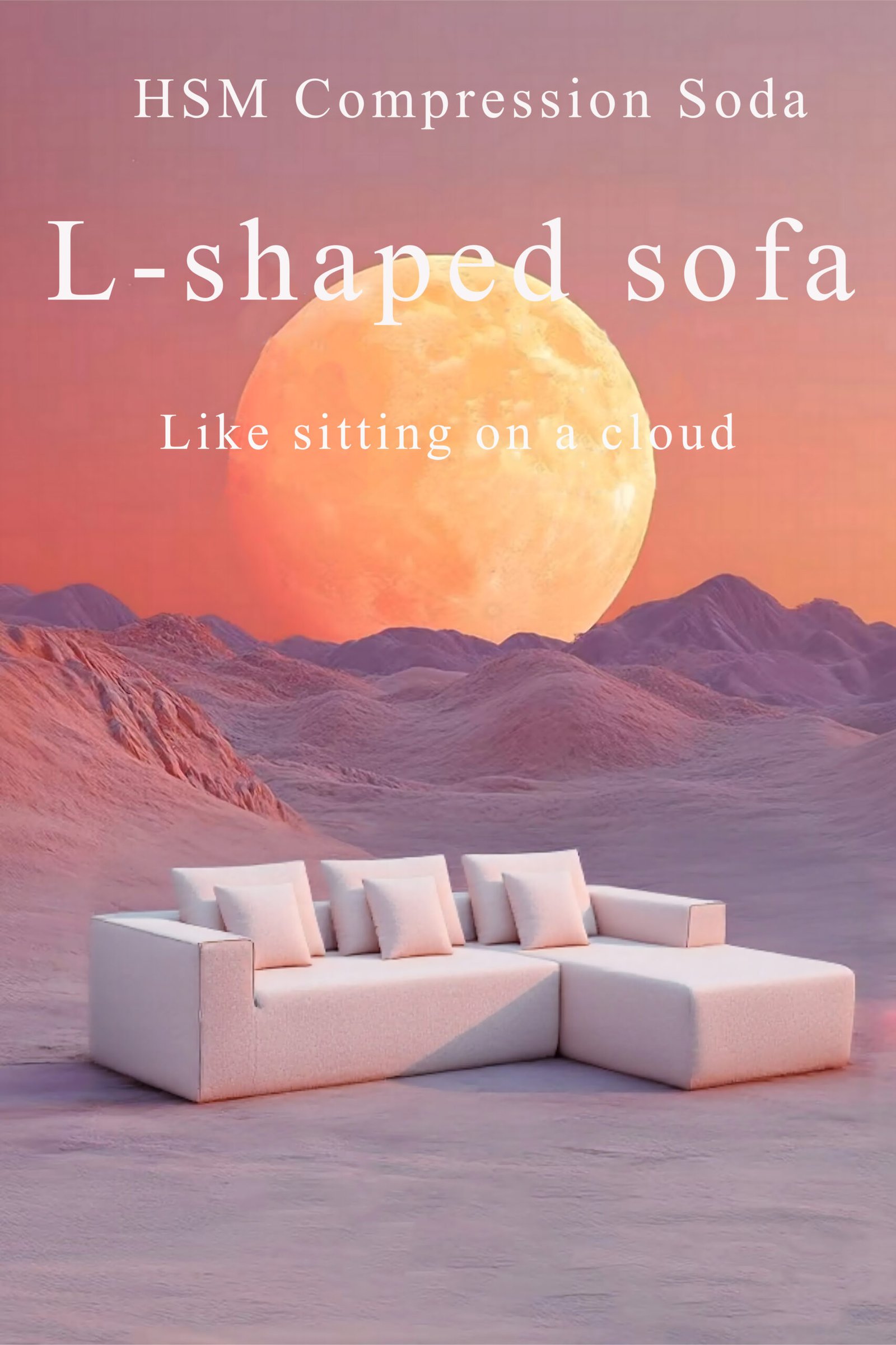

In a crowded market, how do sofa brands stand out?

By turning ordinary sofas into brand ambassadors—compressed sofa suppliers use custom branding to deliver both function and identity.

From logo placement to packaging design, suppliers handle every detail to ensure your product carries your unique brand story.

A sofa is not just for sitting. It's for selling your brand.

What does the custom branding process look like?

Branding starts long before the product is made.

Suppliers begin with deep client consultations to understand visual identity, positioning, and end-user expectations.

They ask:

- What’s your logo? Where should it go?

- What are your core brand colors?

- What emotions should the product evoke?

- Who is your target buyer?

These questions help the supplier map out everything from color schemes to unboxing experience. A collaborative discovery process ensures no detail is missed.

How do suppliers collaborate on custom sofa designs?

Once branding goals are clear, it’s time to bring them to life.

Suppliers and clients co-create designs through digital tools, samples, and revisions.

What happens during design collaboration:

- Clients submit brand guides, product specs, and visual references

- Suppliers use CAD tools to create branded mockups

- Feedback rounds refine color, size, placement

- Virtual previews or physical samples are approved before production

This iterative process ensures both functionality and aesthetic alignment—your sofa not only looks good, but also makes sense for shipping and cost.

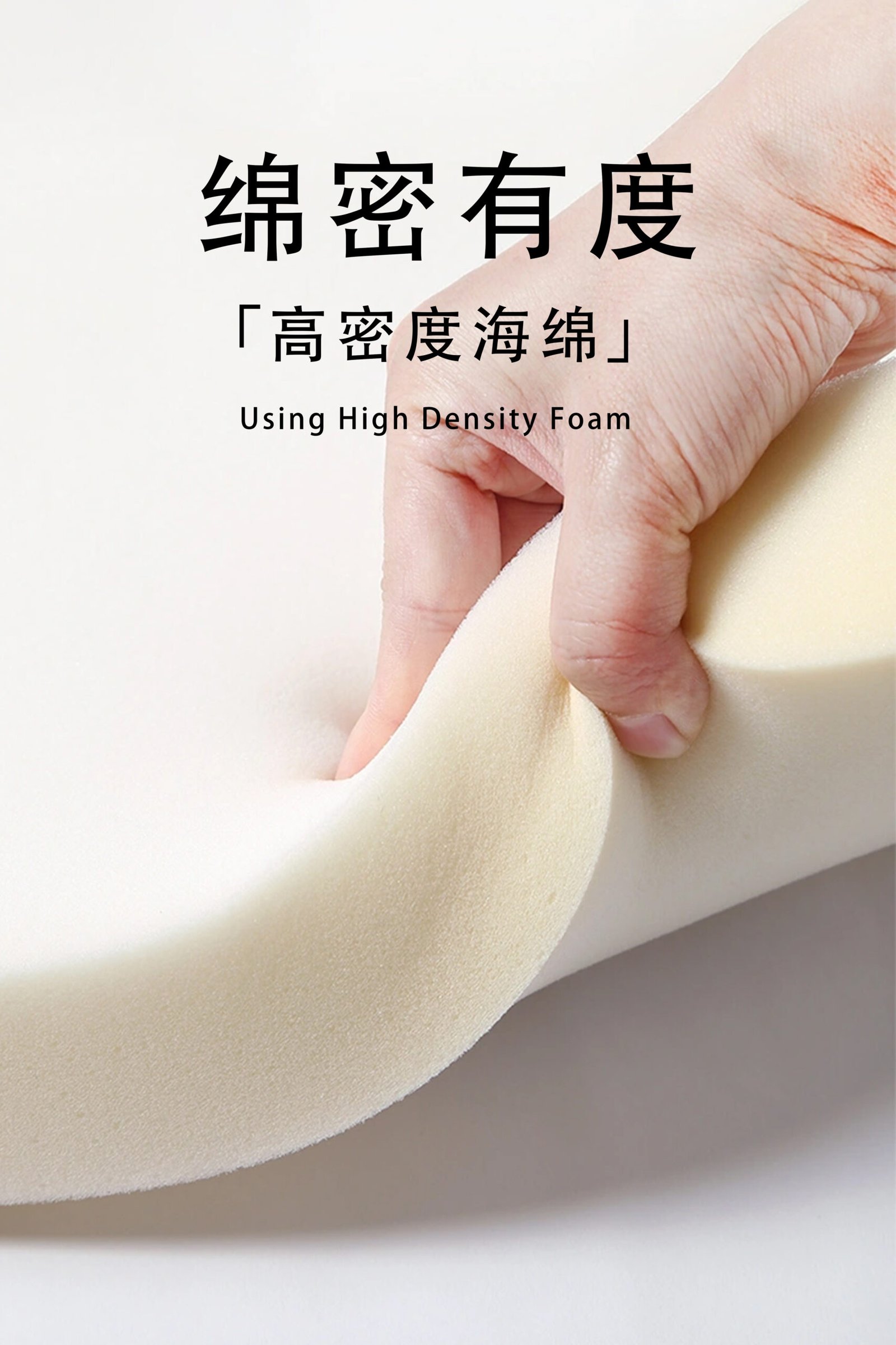

How do suppliers choose the right materials for branding?

Material matters—a lot.

Suppliers select fabrics and frames that work well with the chosen branding method, whether embroidery, print, or embossing.

Factors they consider:

| Material Type | Ideal Branding Method | Notes |

|---|---|---|

| Polyester | Heat transfer, embroidery | Popular for its durability |

| Leatherette | Debossing, screen print | Offers a premium feel |

| Linen blends | Embroidery, digital print | Natural texture for lifestyle brands |

Suppliers also test material samples to ensure colors hold fast and branding doesn't fade or peel over time.

What printing techniques are used for sofa branding?

Not all branding is printed—some is stitched, pressed, or fused.

Suppliers use different techniques based on budget, volume, and visual impact.

Popular methods include:

- Digital printing: Vibrant colors, best for intricate logos

- Embroidery: Durable and premium, adds texture

- Heat transfer: Fast and cost-effective for large batches

- Debossing: Subtle and sophisticated, great for leather finishes

Every method is tested for durability through rub tests, heat resistance checks, and lightfast evaluations to ensure long-lasting branding.

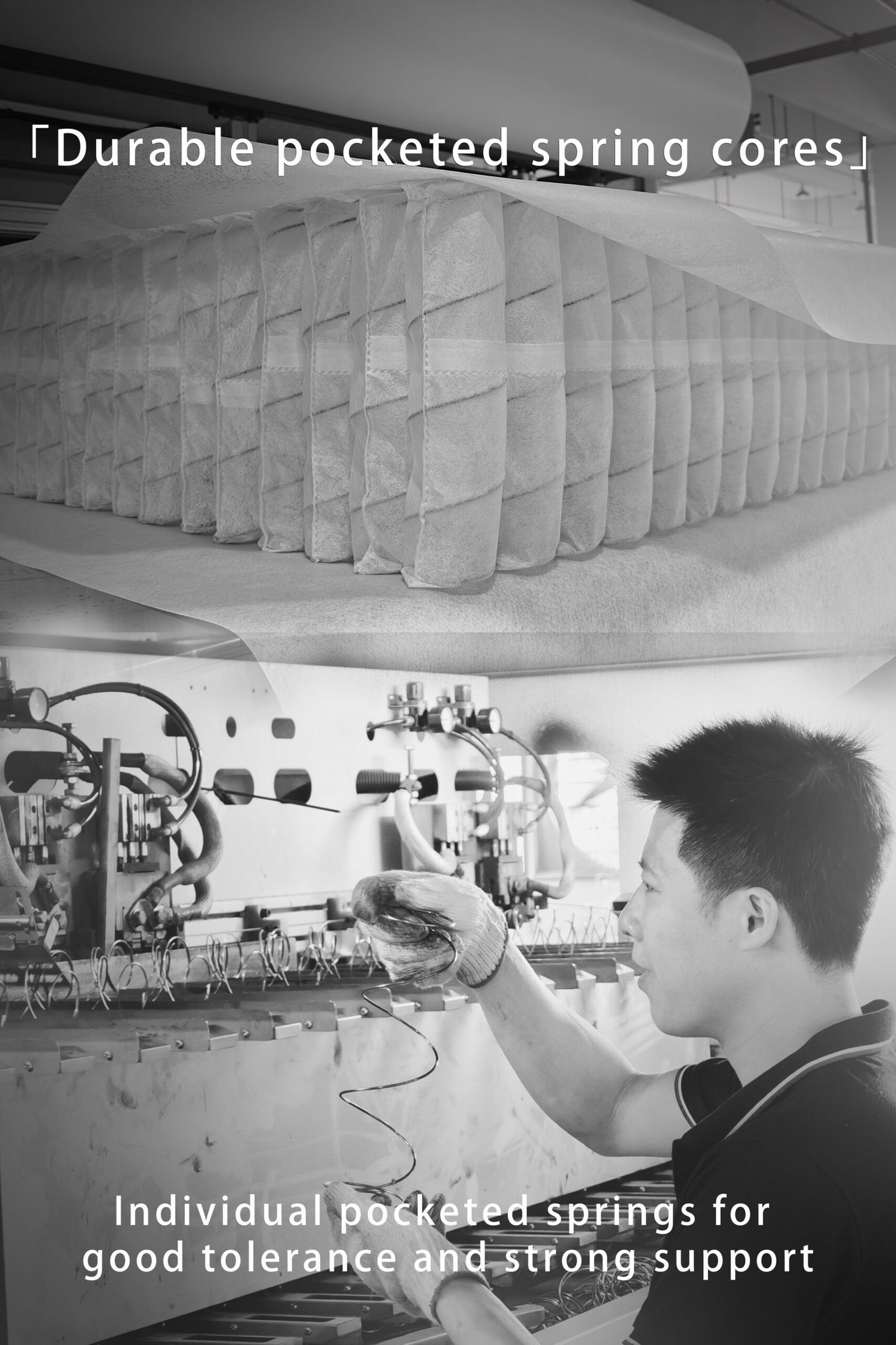

How do suppliers ensure quality during branding?

Branding must be precise—misaligned logos ruin credibility.

That’s why suppliers enforce strict quality control during and after branding application.

Key QC checks include:

- Logo placement accuracy (±2mm tolerance)

- Color matching with Pantone references

- Stitch alignment and thread quality (for embroidery)

- Adhesion tests (for heat transfers)

Every branded unit is inspected before packaging. Any unit that fails QC is reworked or rejected. Suppliers understand: your brand’s reputation is riding on every sofa.

How is branding extended to packaging and shipping?

The experience doesn’t end when the sofa is made—it continues with the box.

Suppliers offer branded packaging options to reinforce identity and create a memorable unboxing.

They can add:

- Custom-printed cartons

- Branded instruction manuals

- Thank-you cards or QR codes

- Logo labels or tapes

For e-commerce sellers, this is critical. Packaging is often the first physical brand touchpoint for the customer.

How do suppliers handle revisions and scalability?

A branding plan that works for 100 units might fail at 10,000.

Suppliers offer scalable branding workflows and clear revision protocols.

They:

- Save digital assets and templates for reuse

- Offer tiered branding options for different budget levels

- Build SOPs for logo application at every production stage

- Allow clients to test small batches before committing

This structure ensures consistent results, even as order sizes grow or product ranges expand.

What compliance and certifications are involved?

Custom-branded products still need to meet safety and legal requirements.

Suppliers help clients navigate labeling laws, flammability standards, and export compliance.

Certifications they may support:

- REACH / RoHS: For chemical safety

- OEKO-TEX: Fabric health compliance

- ISO 9001: Process quality

- FIRA / BIFMA: Structural integrity

Branded tags and labels can include compliance marks, ensuring trust across global markets.

Conclusion

Custom branding turns a sofa into a sales tool.

Compressed sofa suppliers don’t just make products—they bring brands to life.

From early sketches to final packaging, they manage every step with precision and passion. In a fast-moving market, that kind of partnership is not just useful—it’s essential.