Need to fulfill hundreds of sofa orders with one smooth operation? Compressed sofa suppliers have the process dialed in—here’s how they pull it off.

Compressed sofa suppliers handle bulk orders by combining efficient planning, scalable manufacturing, optimized packaging, and integrated logistics systems—ensuring fast delivery without compromising on quality.

Let me show you how each piece of this bulk-order puzzle fits together.

How do compressed sofa suppliers qualify for bulk order production?

Bulk orders aren’t just “bigger orders.” They demand infrastructure, systems, and experience.

Suppliers who can handle bulk orders usually have:

- At least 10+ years of production experience

- Automated production lines for volume scaling

- A dedicated team for OEM/ODM requests

- Certified QC systems (like ISO 9001)

- Case studies or references from past high-volume clients

These suppliers are prepared to meet tight deadlines with consistency and speed.

What’s involved in planning a bulk sofa order?

Planning begins even before the first sofa is made.

Suppliers plan bulk orders by forecasting demand, locking in materials, scheduling production, and assigning resources in advance.

Here’s what that looks like:

- Forecasting: Based on past orders or projected launch volume

- Scheduling: Slotting bulk orders into dedicated production weeks

- Resource Allocation: Ensuring enough foam, fabric, wood, and labor

- Timeline Agreement: Shared with the buyer up front

This upfront coordination prevents production delays or material shortages down the line.

How do they manage materials and inventory?

Bulk production eats materials fast. Smart suppliers stay ahead of the curve.

To meet large order volumes, compressed sofa suppliers build strong relationships with raw material vendors and manage inventory with software.

They use tools like:

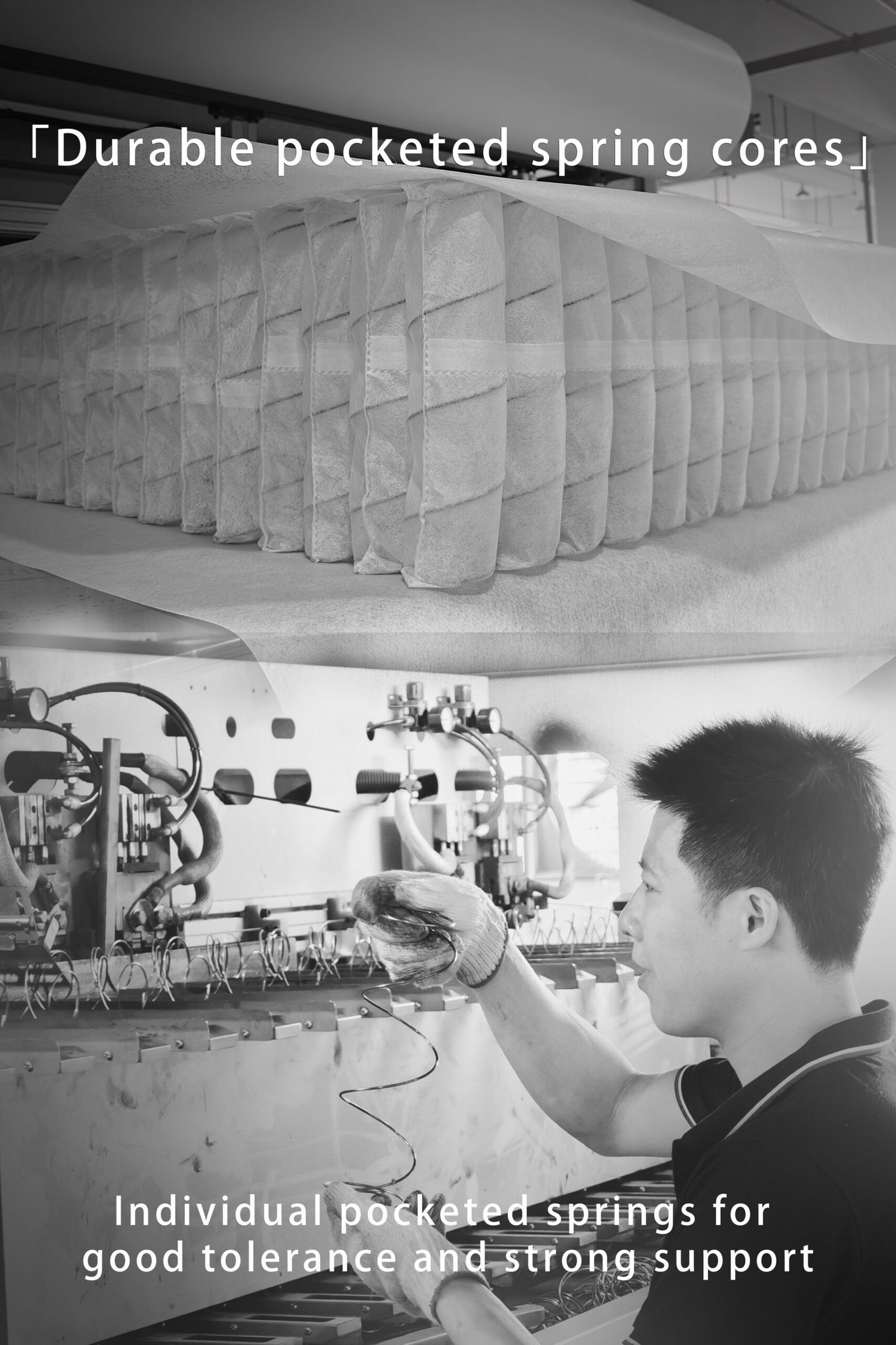

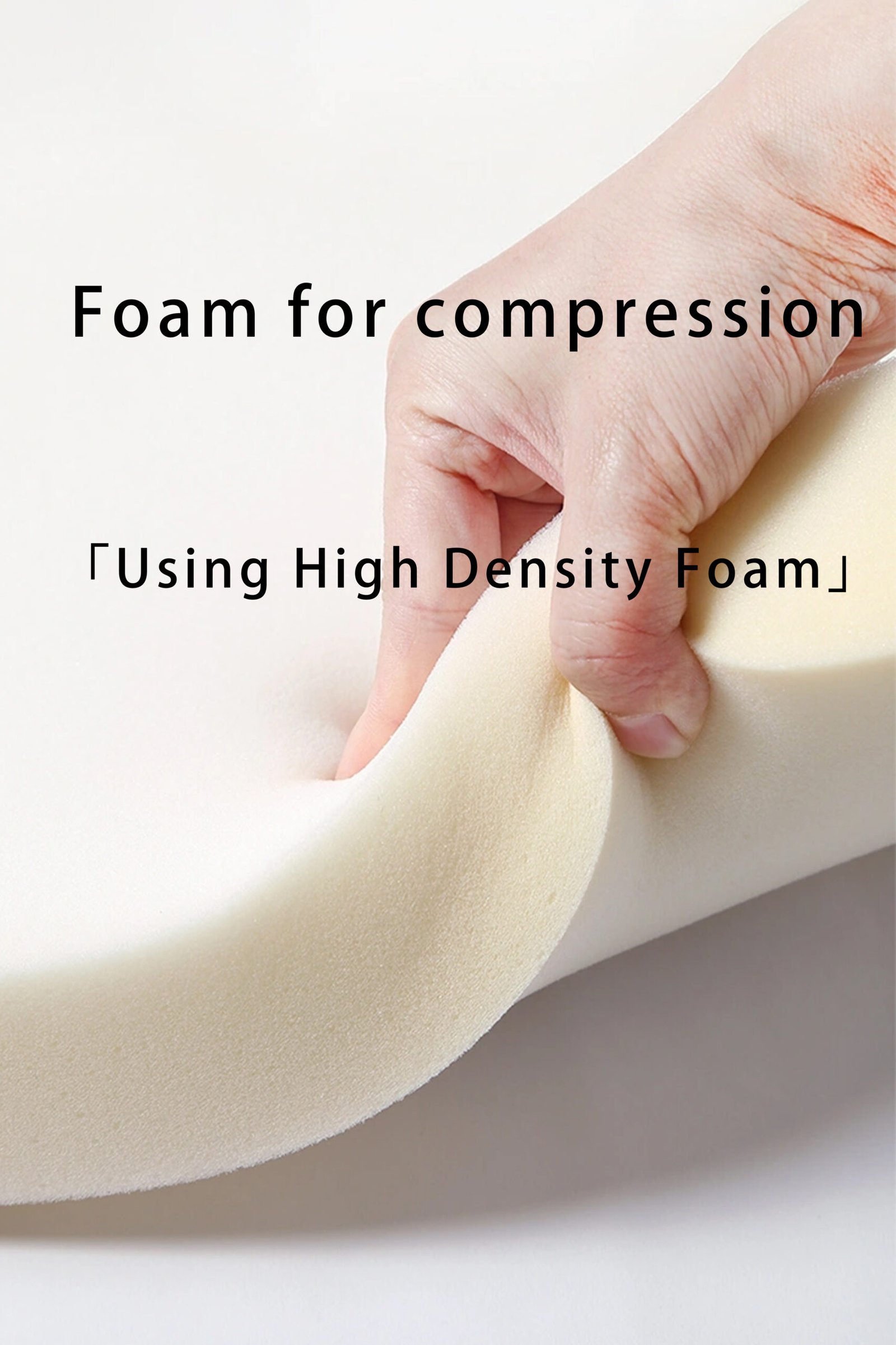

- Reorder point systems for foam, fabric, and springs

- Just-in-time (JIT) strategies for high-demand materials

- Bulk purchasing contracts to lock in prices and availability

- Barcode/RFID tracking inside warehouses

This keeps production flowing—even during global supply chain hiccups.

What makes their production process scalable?

You can’t build 500 sofas a week with manual labor alone.

Suppliers use lean manufacturing, automation, and modular design principles to scale up sofa production.

Key production strategies:

- CNC fabric and foam cutting for precise and fast prep

- Assembly line stations for modular sofa components

- Continuous improvement loops to eliminate waste

- Workforce shift planning to add labor without burnout

With these systems, a supplier can double or triple output—without dropping quality.

How do suppliers maintain quality at scale?

More orders = more chances for something to go wrong—unless you build in quality checks.

Compressed sofa suppliers maintain high quality during bulk runs with multi-stage QC, random audits, and third-party inspections.

Here’s a typical QC system:

| Stage | What’s Checked |

|---|---|

| Incoming materials | Foam density, spring elasticity, fabric |

| In-process | Stitching, frame integrity, dimensions |

| Finished product | Compression integrity, defects, labeling |

| Pre-shipment | Carton quality, barcode matching |

Some buyers even request third-party QA labs (like SGS) to run compliance checks.

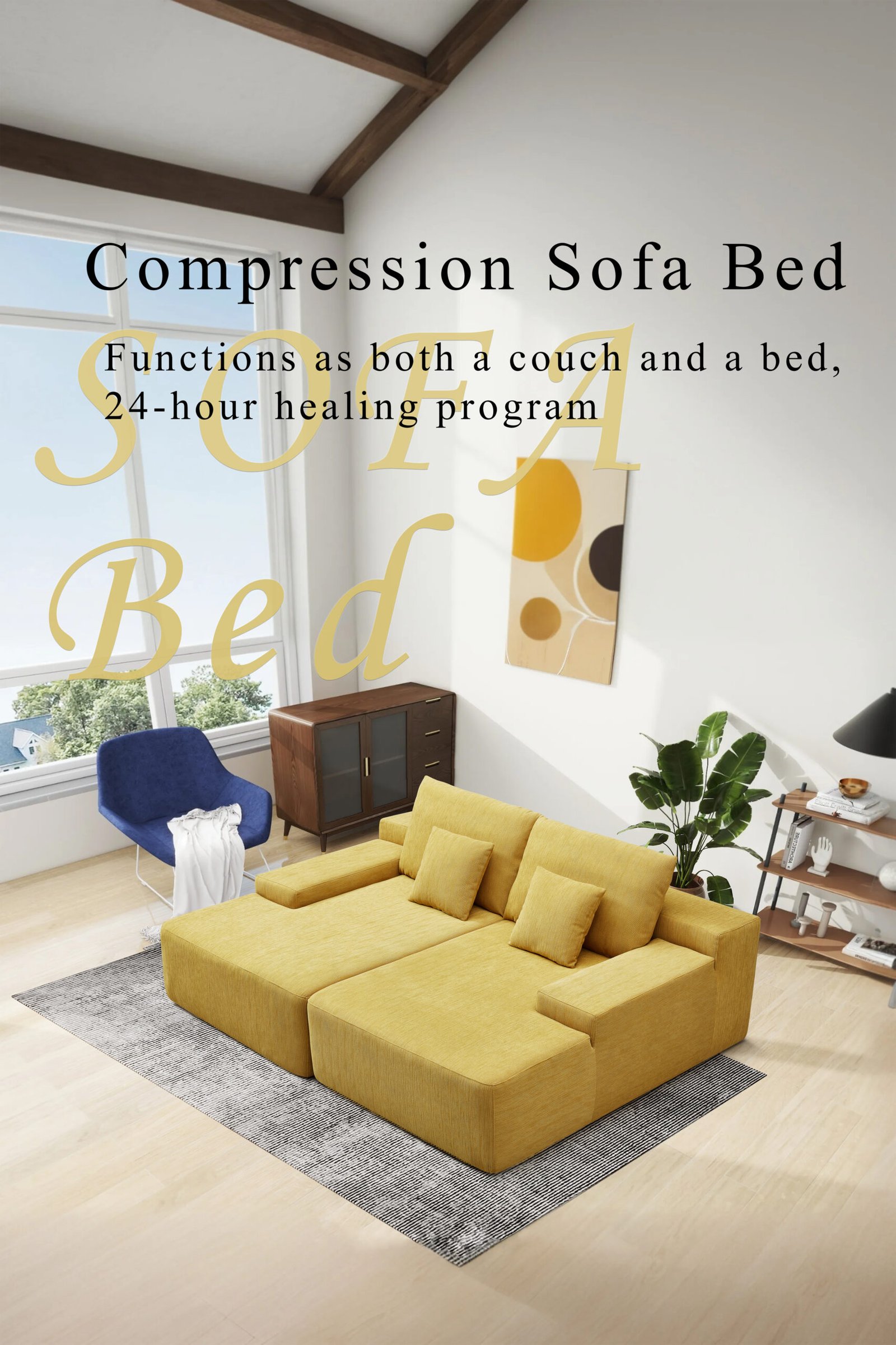

What about packaging and compression at scale?

You can’t ship 1,000 sofas without space-efficient packaging.

Suppliers use heavy-duty compression machines and durable packaging materials to reduce volume and protect during transit.

Key features include:

- Vacuum-pack sealed foam units

- Reinforced honeycomb cartons

- Moisture barrier film + corner protectors

- Custom labels or QR codes for tracking

Compressed packaging reduces warehouse space and cuts freight costs—perfect for LCL/FCL shipments.

How is logistics coordinated for large orders?

Bulk orders don’t end at the factory gate.

Suppliers work with freight forwarders and logistics partners to manage container loading, customs, and last-mile delivery.

They coordinate:

- Container planning: Based on order volume and destination

- Documentation: Commercial invoice, packing list, bill of lading

- Real-time tracking: Using ERP or freight apps

- Drop-shipping: For e-commerce fulfillment (if needed)

Some suppliers even offer DDP shipping terms to simplify importing.

Can suppliers customize bulk orders?

Bulk doesn’t mean boring.

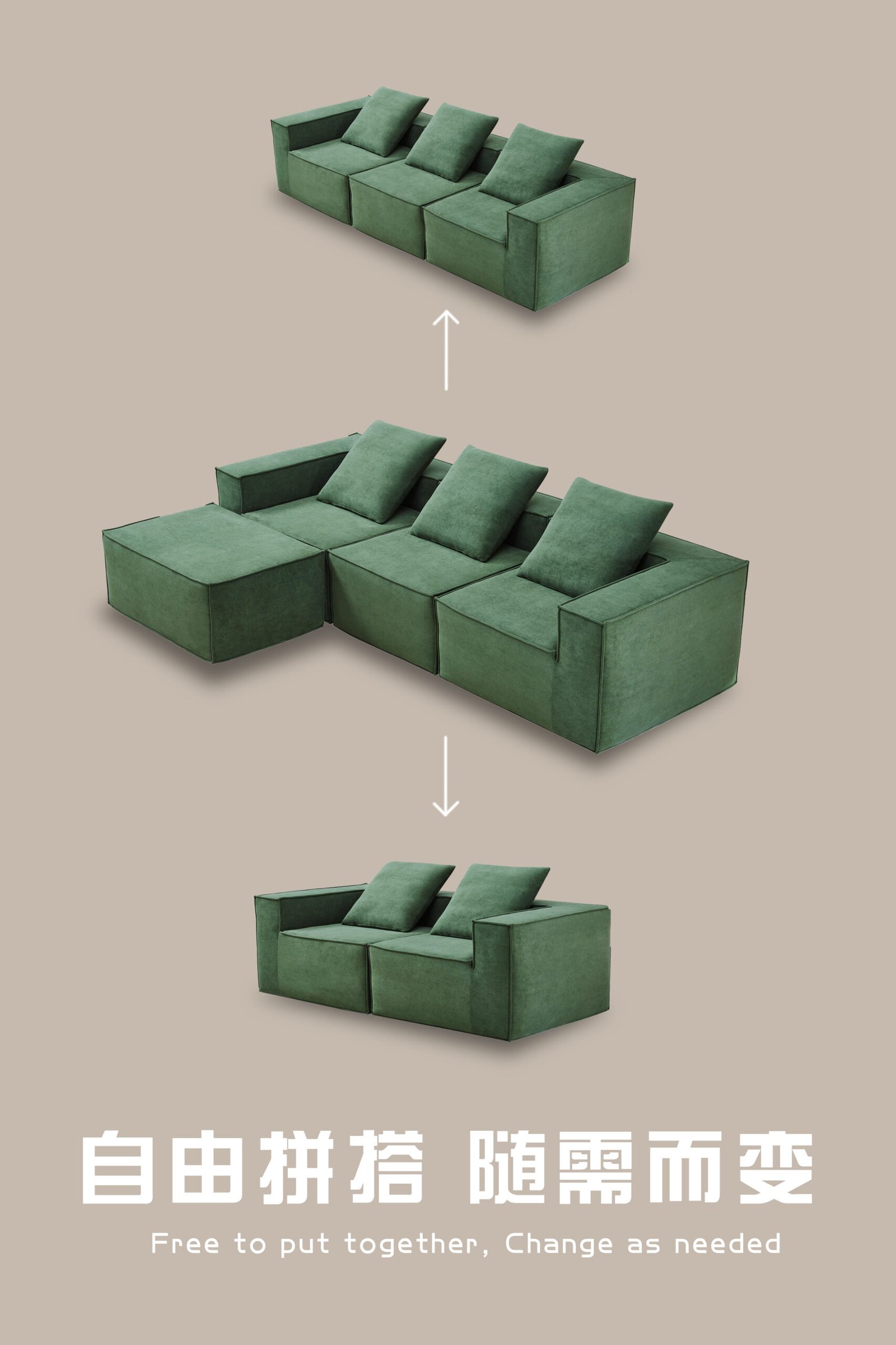

Suppliers offer customization options even for large orders—like fabric colors, logos, and carton designs.

Popular customizations include:

- Brand labels or hangtags

- Retail-ready packaging

- Bespoke fabric combinations

- Private label documentation

As long as MOQs are met, most requests can be handled without delaying timelines.

Do suppliers follow sustainability practices?

Green isn’t a trend—it’s a requirement for many buyers.

Top compressed sofa suppliers implement eco-friendly practices in bulk production and shipping.

Sustainability steps include:

- Using recycled or recyclable packaging

- Low-emission foam and water-based glues

- Energy-efficient machinery

- Partnering with green-certified logistics carriers

Ask for certifications like FSC, REACH, or OEKO-TEX during supplier vetting.

Conclusion

Compressed sofa suppliers handle bulk orders with precision. From supplier vetting and material sourcing to smart compression and streamlined shipping, every part of the process is optimized for scale. That’s how they meet big orders—fast, affordable, and at quality you can trust.