Furniture is getting smarter, faster, and greener. But traditional sofas haven’t kept up. Compressed sofa suppliers are about to change that.

The future of compressed sofa suppliers lies in modular design, sustainable materials, smart logistics, and AI-driven customization—these innovations are reshaping how furniture is made, sold, and shipped.

If you're in the furniture business or considering compressed sofas, now’s the time to watch how suppliers are evolving. Let’s explore what’s coming next.

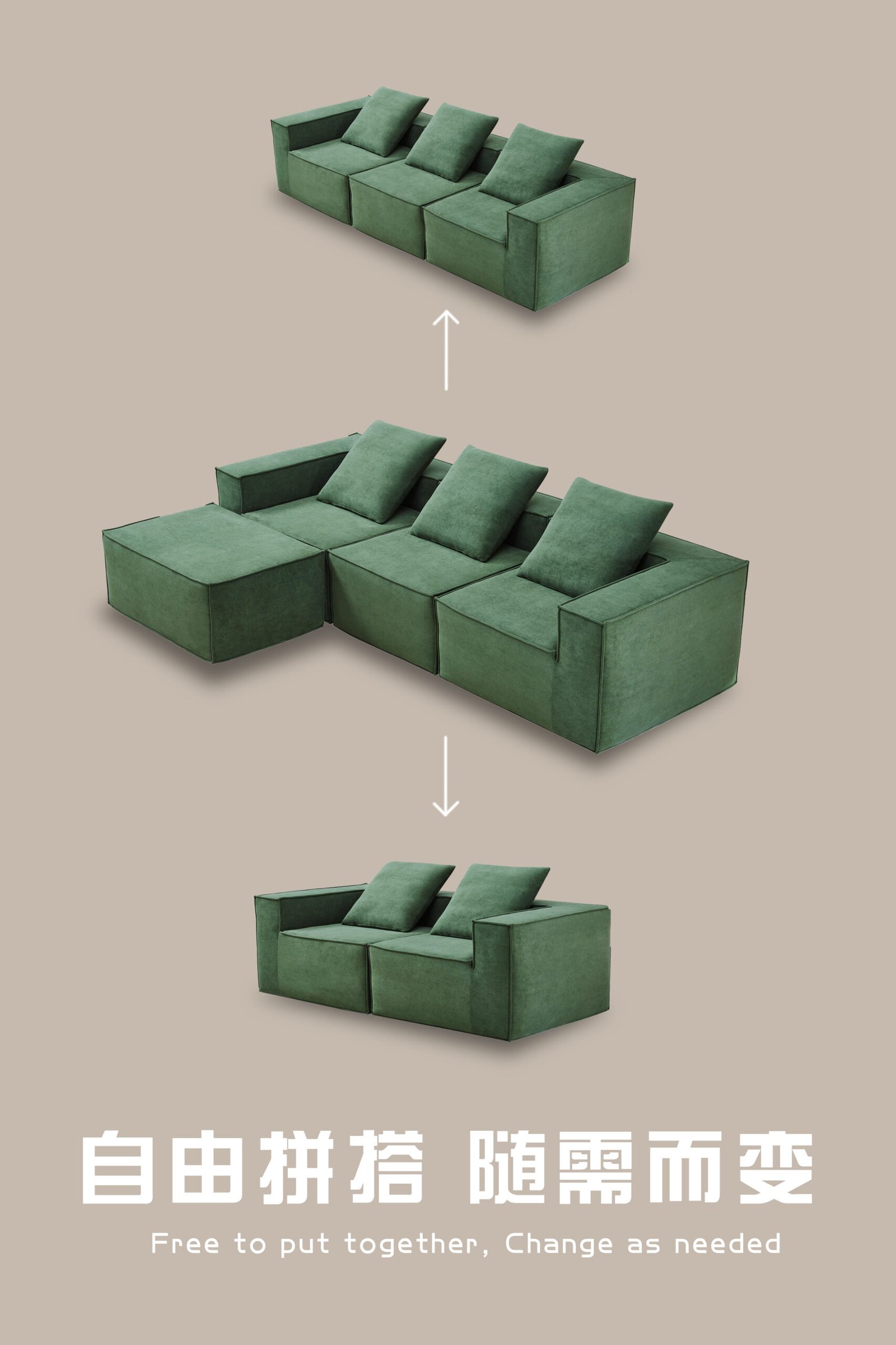

Are modular and multifunctional designs the next big thing?

People want flexibility. Small apartments, shared spaces, and hybrid work-life homes need furniture that can adapt. That’s the pressure. Modular design is the answer.

Compressed sofa suppliers are investing in modular systems that let users change shape, function, or layout based on real-life needs—without losing compression efficiency.

I saw this firsthand when a customer asked for a 3-seater that could transform into two lounge chairs. We developed it—and it ships compressed in two boxes.

Key Features of Modular Compressed Sofas

| Feature | Function |

|---|---|

| Detachable seats | Change from sofa to sectional or ottoman |

| Foldable arms/backs | Create beds or loungers from the same frame |

| Hidden storage | Maximize use in small rooms |

| Clip-lock bases | Easy reconfiguration and assembly |

These aren’t gimmicks. These are real solutions for urban living. As cities grow, modularity will define the next generation of compressed sofas.

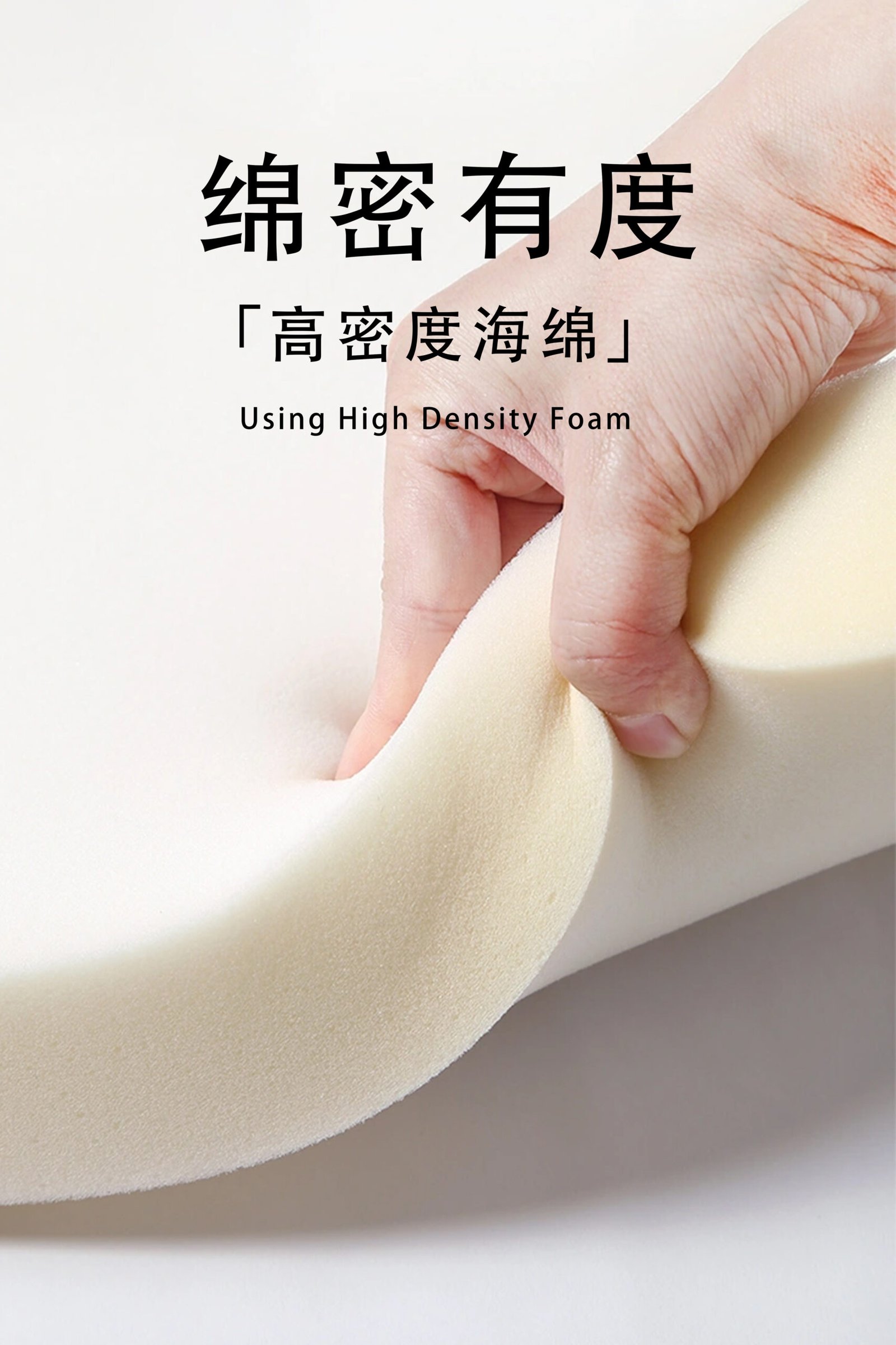

Will eco-friendly materials become standard?

Sustainability is no longer optional. Customers care. Retailers care. Governments care. If the product isn’t green, it won’t go far.

Suppliers are switching to eco-certified foams, recycled fabrics, water-based adhesives, and FSC-certified frames to meet the demand for sustainable compressed sofas.

I made the switch to OEKO-TEX and recycled PET fabric in 2023. The response? Stronger sales and easier access to European retailers with strict import policies.

Popular Sustainable Materials

| Material | Source | Benefit |

|---|---|---|

| Recycled foam | Manufacturing scraps | Reduces landfill waste |

| PET fabric | Recycled plastic bottles | Durable and stain-resistant |

| FSC-certified wood | Responsible forestry | Lower deforestation impact |

| Water-based glue | Non-toxic adhesives | Safer and compliant with EU laws |

More countries are introducing carbon caps and material regulations. Suppliers who adapt now will win tomorrow.

How will AI and digital tools transform customization?

Buyers want unique sofas—but they don’t want delays. Customization used to mean slow production. That’s changing.

The future of compressed sofa customization lies in AI-powered configurators, 3D preview tools, and on-demand manufacturing that reduce lead time and increase accuracy.

I use a real-time design tool on my site that lets clients choose fabric, shape, and leg type—then sends specs directly to the production floor.

Tools Reshaping Sofa Customization

1. 3D Configurators

- Let buyers view models in their room

- Instantly swap colors, materials, and layouts

- Auto-generate production-ready blueprints

2. AI Design Assistants

- Recommend layouts based on space size and use

- Predict color trends by region or customer profile

- Reduce back-and-forth and shorten sales cycles

3. Digital Twins

- Every sofa model has a virtual version

- Tracks materials, packaging spec, and recovery performance

- Helps monitor quality over time

Customization doesn’t have to slow you down. Smart tools mean faster, better results for both the factory and the customer.

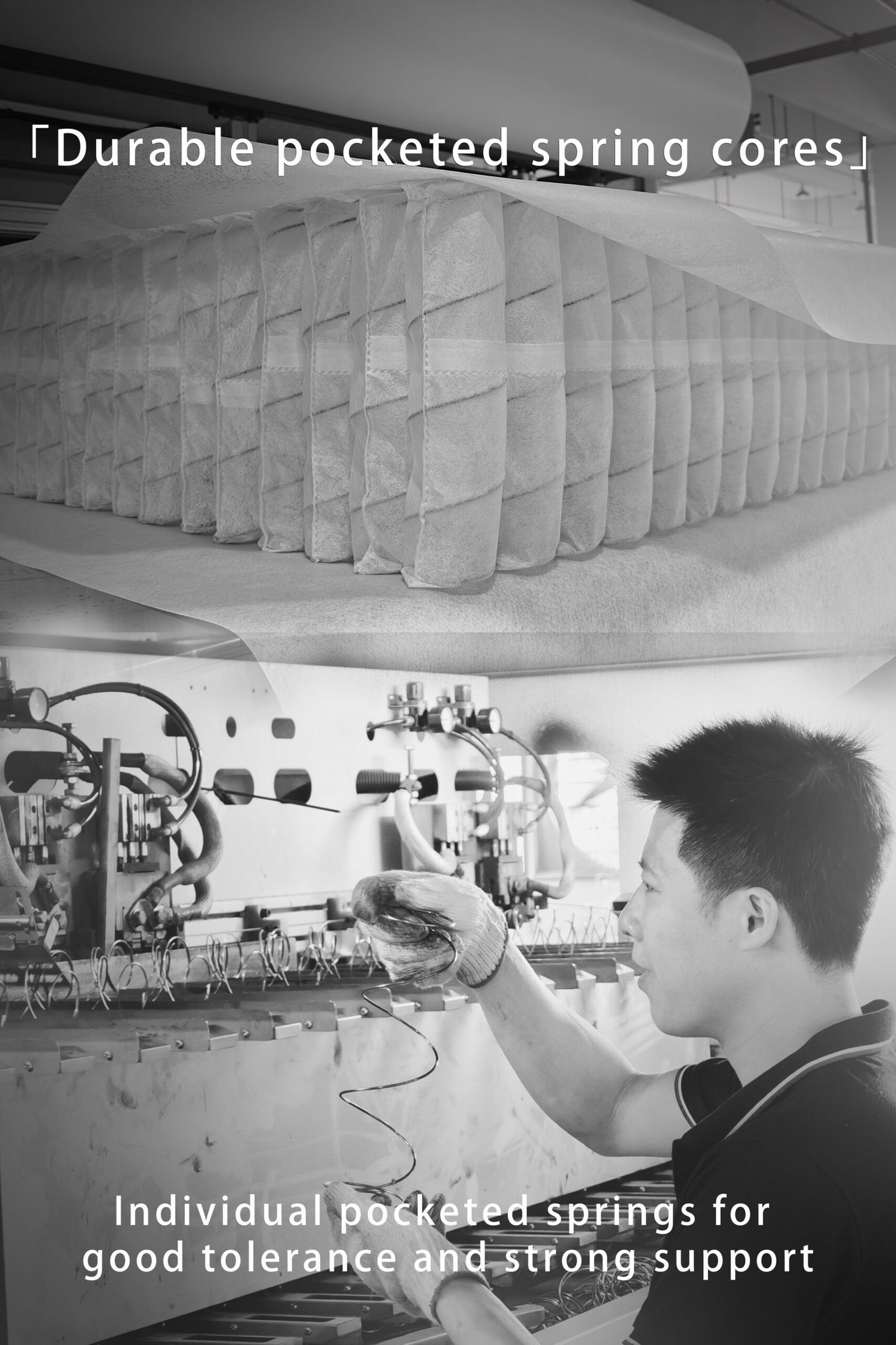

Will automation improve compression efficiency?

Compression works—but manual work slows things down. And quality depends on consistency. That’s where automation wins.

Advanced compression lines, robotic arms, and smart vacuum sealing are making compressed sofa manufacturing faster, safer, and more consistent than ever.

At HSM, we upgraded our compression system in 2024. Output increased by 35%, error rate dropped by 80%, and worker injuries dropped to zero.

What’s New in Compression Automation?

| Tech | Function | Benefit |

|---|---|---|

| Robotic arms | Position and press foam/fabric evenly | Reduces human error |

| Smart vacuum sensors | Adjust sealing pressure by product | Prevents over-compression |

| Modular conveyor lines | Scale based on order size | Ideal for factories of any size |

Automation doesn’t just boost volume. It protects your brand reputation with consistent results.

What does the global market want next?

Sofa preferences are no longer local. Global buyers want style, sustainability, and speed—all at once.

Compressed sofa suppliers are adapting to international demand by offering design localization, multilingual support, and region-specific compliance built into production.

We now offer sizing and material presets by market—wider seats for the US, firmer cushions for Japan, sustainable fabric for Germany.

Market-Specific Adjustments That Work

| Country | Key Preference | Supplier Response |

|---|---|---|

| USA | Wide armrests, soft cushions | Added 3-seater XL option |

| Canada | Neutral tones, eco-certification | Use GREENGUARD-certified foam |

| Germany | Tight fabric weave, no off-gassing | Offered EU REACH compliance |

| Japan | Narrow frames, fast recovery foam | Introduced 2-layer decompression foam |

The compressed sofa business isn’t one-size-fits-all anymore. Smart suppliers listen and localize.

Conclusion

Compressed sofa suppliers are no longer just solving shipping—they’re leading trends in tech, sustainability, and design. The future belongs to those who adapt fast and think smart.