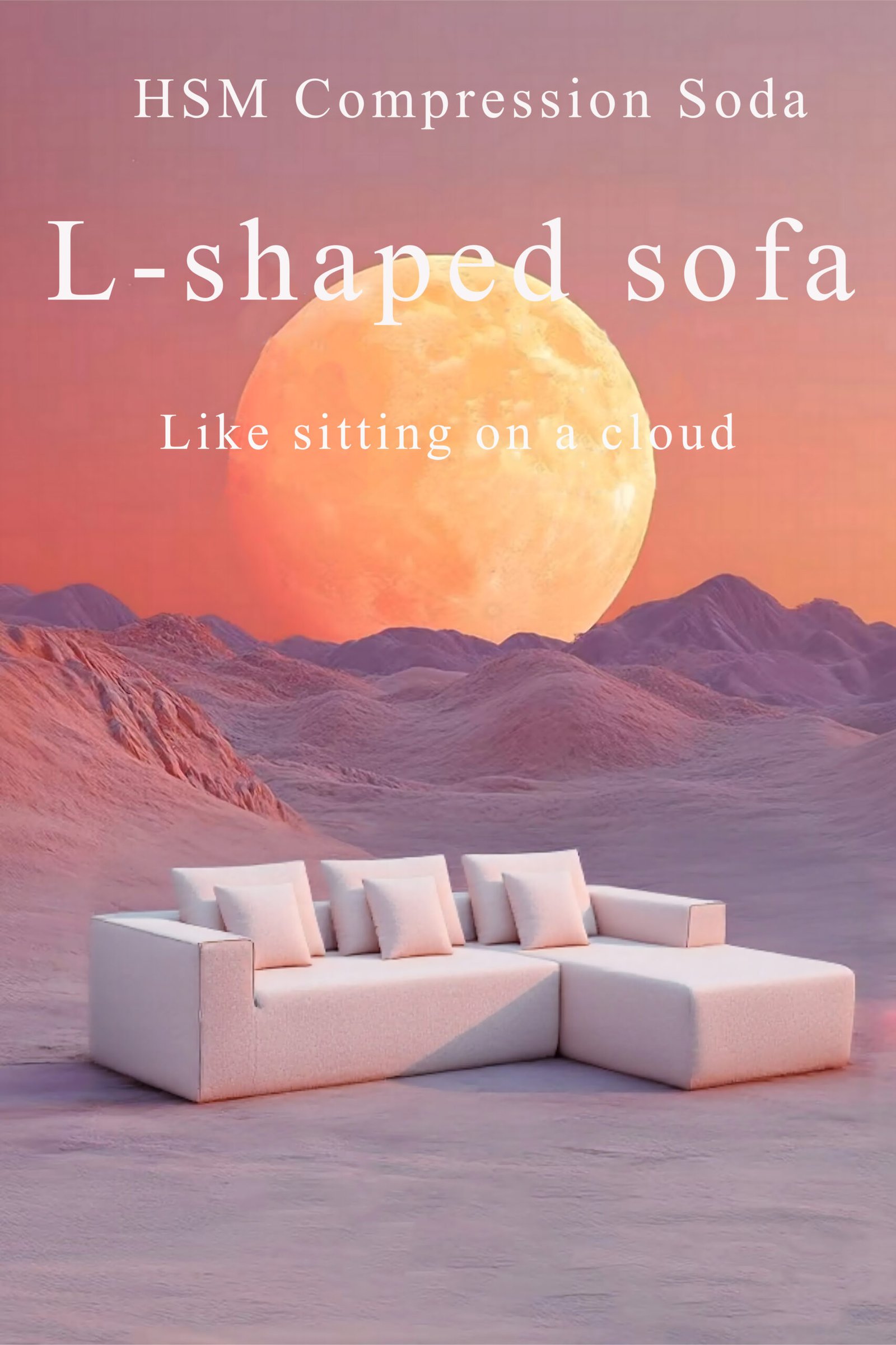

Sofas are big, heavy, and hard to move—until you meet the compression sofa. But how exactly does it shrink and bounce back?

The innovative technology of compression sofas lies in their modular structures, memory-based foam systems, and compression-friendly manufacturing techniques that allow the furniture to shrink for shipping and expand without damage.

Let’s break down the real tech magic that makes compressed sofas possible—and why it’s changing how we design, ship, and use furniture.

How do compression sofas work technically?

It seems like magic—a full-sized sofa packed into a tiny box. But it's not magic. It's material science and modular engineering.

Compression sofas rely on a combination of memory foam, elastic fabrics, flat-pack modular components, and vacuum-packing technology to reduce their volume for shipping and storage.

Technical Components Behind the Design

| Technology Element | Purpose |

|---|---|

| Memory Foam Layers | Compress easily and expand back to shape without deforming |

| Elastic Upholstery | Allows stretch and contraction without tearing |

| Modular Frame Sections | Separate parts that can be compacted and reassembled |

| Vacuum Compression Bag | Removes air to reduce volume during packaging |

The first time I opened a vacuum-packed compressed sofa at our workshop, I couldn’t believe how fast it expanded. In less than 60 seconds, it grew from a 20cm-thick slab to a full seat with armrests. That’s not design fluff—that’s tested resilience.

What are the key materials enabling compression?

Ordinary sofas use materials that crush or tear when compressed. Compression sofas need smarter stuff.

The tech starts with materials—especially foam that can collapse under pressure and then bounce back, and fabrics that stretch without breaking.

Essential Material Tech

🧠 Memory Foam (Viscoelastic Polyurethane)

- Compresses evenly

- Returns to original shape without damage

- Provides ergonomic comfort

🧵 Elastic Knit or Spandex-Blend Upholstery

- Adapts to compression and expansion

- Doesn’t wrinkle or sag over time

🔧 Flexible Plywood or Reinforced Plastic Frames

- Modular and lightweight

- Strong enough to support weight after reassembly

Many of the newer models also integrate mesh ventilation panels to help foam “breathe” faster during expansion.

How is compression achieved in production?

It’s one thing to fold up a couch. It’s another to do it at scale, without damage, thousands of times a week.

Compression sofas are produced using a multi-step industrial process that includes foam baking, modular pre-assembly, and automated vacuum sealing.

Step-by-Step Manufacturing Process

-

Foam Shaping & Baking

Foam is cut into sheets, heated to activate elasticity, and cooled under pressure to condition recovery performance. -

Frame Modulation

The sofa’s base, arms, and back are pre-built as interlocking panels or collapsible frames. -

Layer Integration

Cushions and covers are attached using stretchable adhesives or Velcro. -

Vacuum Compression & Sealing

Entire unit is placed into a thick plastic film and compressed under industrial vacuum pumps. -

Box Packaging

Compressed sofa is inserted into flat-pack cartons with labeled instructions for easy assembly.

This process not only saves storage and shipping costs—it also reduces breakage during transit.

How does technology affect the user experience?

Tech should make life easier—not harder. Luckily, compression sofa technology delivers real-world benefits.

The result of all this innovation is that users get a sofa that’s easy to ship, fast to unpack, and durable in everyday use.

Real User Benefits

- Fast Setup: Most sofas expand in under 10 minutes

- Tool-Free Assembly: No screws, just slots and snaps

- Cleaner Indoor Air: New foams are low-VOC and safe

- Custom Fit: Some models include modular blocks that users can rearrange

One of our Canadian clients told me his favorite part wasn’t the look—it was that he could get the whole sofa into a condo elevator alone.

What are the latest tech trends in compression sofa innovation?

Innovation doesn’t stop at “fits in a box.” Brands are pushing the envelope further with smart features and sustainable upgrades.

The future of compression sofas includes AI-assisted cushioning, 3D-knit covers, and bio-based foam—all aimed at smarter, greener, more personalized furniture.

Emerging Tech Innovations

📱 Smart Sensors in Cushions

- Track weight and pressure for ergonomic feedback

🌱 Eco-Friendly Foams

- Made from soybean oil or recycled plastics

🧵 Seamless 3D-Knit Covers

- Fewer seams, better fit, and machine washable

🧩 Expandable Modules

- Add or remove armrests, chaise lounges, or headrests over time

I’ve personally tested a prototype that includes Bluetooth speakers in the headrest and wireless charging in the arm. It’s no longer just a sofa—it’s becoming a tech hub.

Conclusion

The innovative technology behind compression sofas blends smart materials, modular design, and user-focused engineering. It makes shipping cheaper, setup faster, and everyday use more comfortable—all while fitting into our modern, space-limited lives.