Introduction

For B2B stakeholders in the furniture supply chain, securely sealing and packing compress sofas is essential to maintain product integrity, optimize logistics, and ensure customer satisfaction. Proper sealing and packaging minimize damage risks, prevent contamination, and reduce shipping costs—critical factors for manufacturers, wholesalers, and distributors. This guide outlines five key steps to effectively seal and pack a compress sofa, incorporating industry best practices and quality assurance measures relevant for 2024 and beyond.

Selecting the Right Packaging Materials

The first step is choosing appropriate packaging materials. High-quality vacuum-sealable plastic films, reinforced corrugated cartons, protective foam inserts, and tamper-evident seals are standard in the industry. B2B buyers should verify that all materials are compatible with the sofa’s upholstery and frame, and comply with regulatory and sustainability requirements. Conducting compatibility tests helps avoid material interactions that could compromise product quality and packaging performance.

Preparing and Inspecting the Sofa

Before sealing, the compress sofa must be thoroughly cleaned and inspected. Removing dust, debris, or manufacturing residues from the upholstery and frame is crucial, as these can affect the vacuum seal’s adhesion and overall packaging integrity. Inspect the sofa for any surface defects and ensure all components are properly assembled and ready for compression. Attention to detail at this stage is vital for B2B clients who prioritize consistent product quality and reliability.

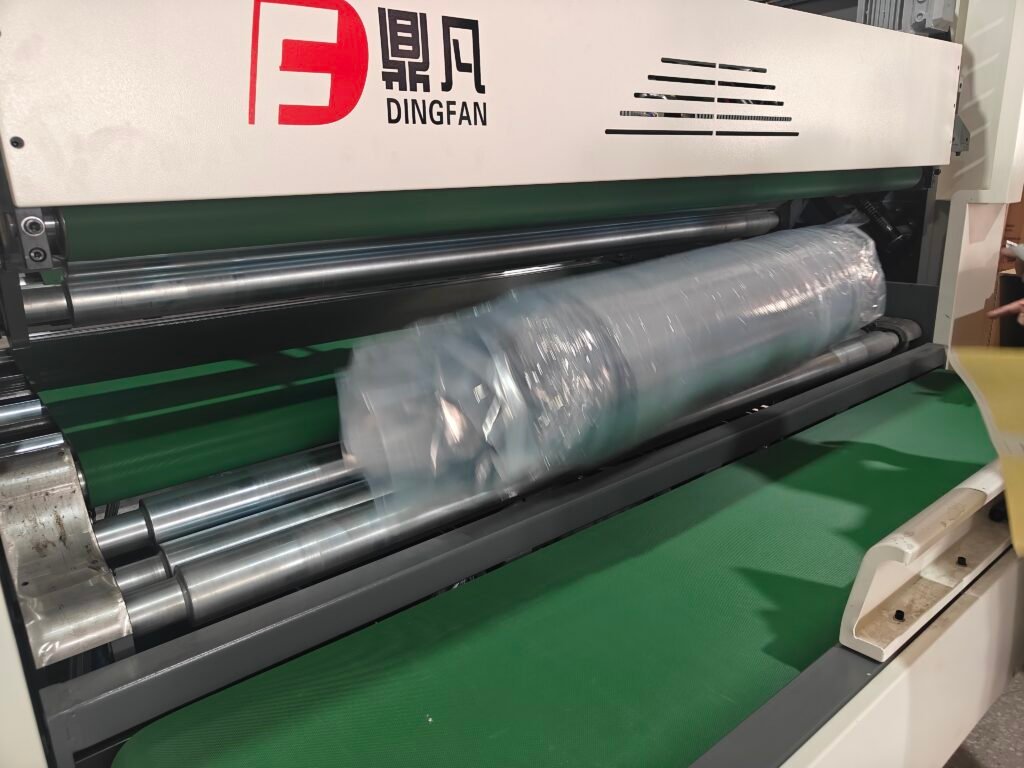

Vacuum Compression and Sealing

Industrial-grade vacuum packaging machines are used to compress the sofa by extracting air, reducing its volume by up to 90%. Once compressed, the sofa is immediately sealed in a durable vacuum bag, ensuring the seal is uniform, airtight, and free from wrinkles or gaps. For high-volume B2B operations, automated sealing equipment is recommended to guarantee consistency and efficiency. Manual sealing may be suitable for smaller batches but requires careful alignment and pressure to avoid incomplete seals.

Securing in Protective Cartons and Applying Tamper-Evident Seals

The vacuum-sealed sofa is placed into a custom-sized, reinforced corrugated carton. Protective foam inserts or air pillows are added to absorb shocks and prevent movement during transit. Tamper-evident seals or security labels are applied to the carton to assure B2B buyers of product authenticity and protection against tampering. Clear labeling with product codes, handling instructions, and destination information streamlines warehouse operations and inventory management.

Quality Inspection, Storage, and Handling

A thorough quality check of the sealed and packed sofa is conducted, inspecting for any visible gaps, misalignments, or packaging defects. The integrity of the vacuum seal and the structural stability of the carton are tested. Packed sofas should be stored in a cool, dry, and well-ventilated environment, away from direct sunlight and excessive humidity. Careful handling during loading and unloading is essential to prevent damage. Proper storage and handling ensure that sofas arrive at their destination in optimal condition, reinforcing brand reliability and competitive advantage for B2B clients.

Conclusion

Sealing and packing compress sofas securely is a multi-step process that requires precision, the right materials, and rigorous quality control. By following these five key steps, B2B manufacturers, wholesalers, and distributors can protect their products throughout the supply chain, reduce costs, minimize returns, and enhance customer trust in 2025 and beyond.